guard and the lo w er c hain span is within 1-1/2

to 2-1/2 inc hes (3.8 to 6.35 cm) ( Figure 30 ).

7. P osition the axle retaining brac k et tight ag ainst

the axle and the frame , then tighten the n ut on

the bolt to secure it in place ( Figure 31 ) and

tor que the n ut to 30 ft-lb (40.7 N ⋅ m).

8. Tighten the n uts securing the axle retaining

brac k et and tor que them to 75 ft-lb (102 N ⋅ m).

9. R e peat ste ps 3 through 8 for the other dri v e

c hain.

10. Star t the engine and raise the buc k et to retur n

the front wheels to the g round.

Hydraulic System

Maintenance

Replacing the Hydraulic

Filter

Important: Do not substitute an automoti v e

oil filter or sev er e h y draulic system dama ge

may r esult.

Chang e the h y draulic filter after the first 8

operating hours and then ev er y 400 operating

hours thereafter .

1. P osition traction unit on a lev el surface .

2. Raise the loader ar ms and install the cylinder

loc ks , stop the engine , and remo v e the k ey .

3. Place a drain pan under the filter .

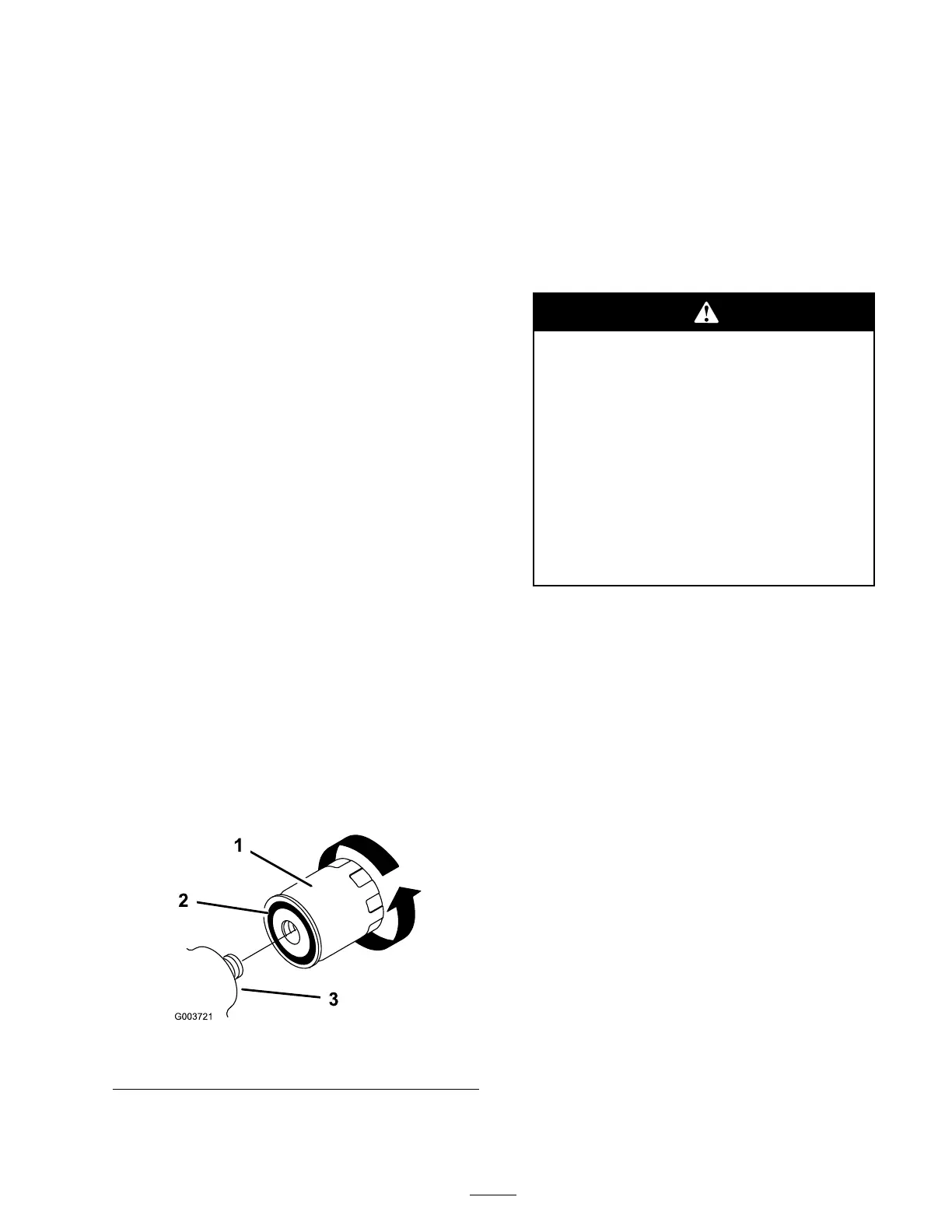

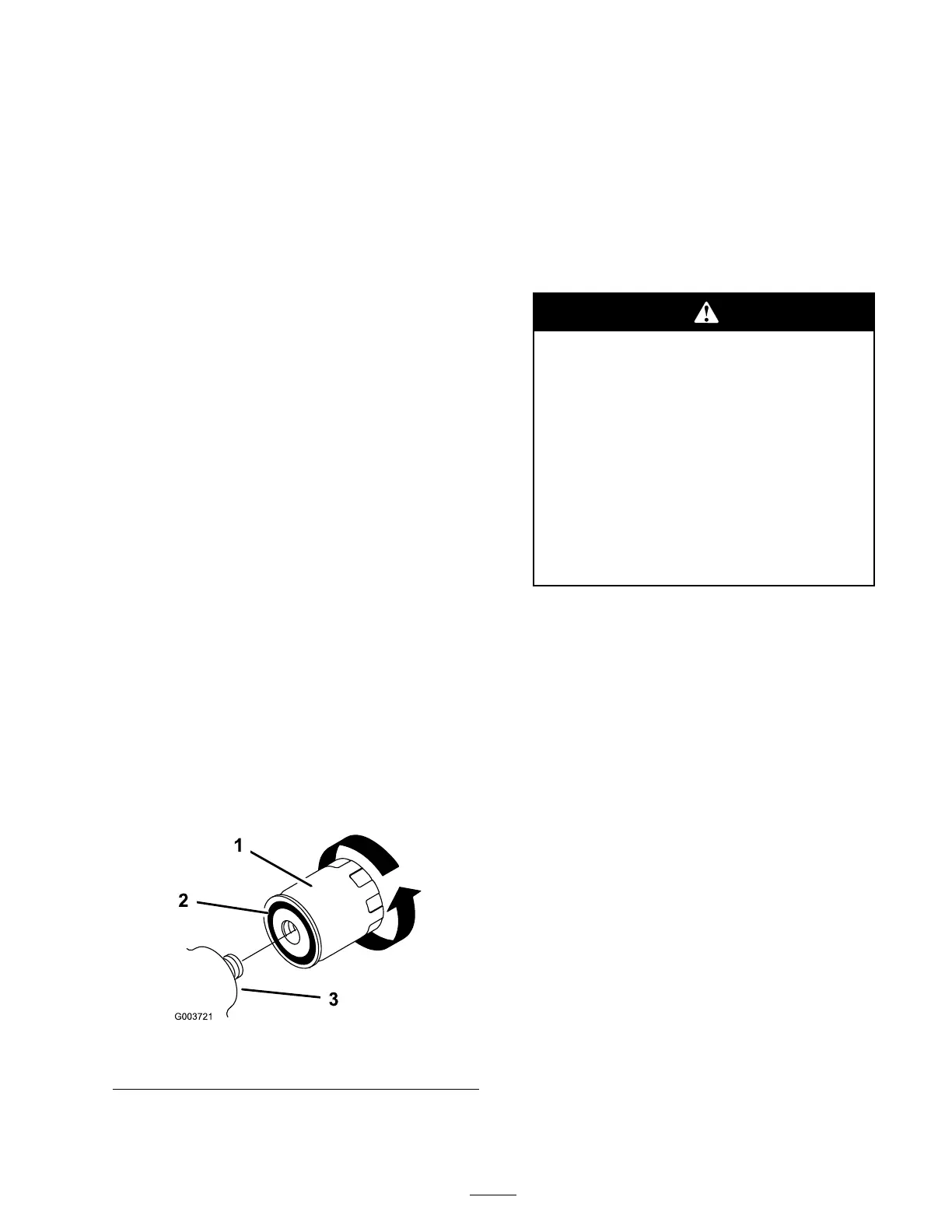

4. R emo v e the old filter ( Figure 32 ) and wipe the

surface of the filter adapter g ask et clean.

Figure 32

1. Hydraulic lter

5. Apply a thin coat h y draulic fluid to the r ubber

g ask et on the re placement filter ( Figure 32 ).

6. Install the re placement h y draulic filter onto the

filter adapter ( Figure 32 ). Tighten it cloc kwise

until the r ubber g ask et contacts the filter

adapter , then tighten the filter an additional

1/2 tur n.

7. Clean up any spilled fluid.

8. Star t the engine and let it r un for about tw o

min utes to purg e air from the system.

9. Stop the engine and c hec k for leaks .

Hy draulic fluid escaping under pr essur e

can penetrate skin and cause injur y .

F luid injected into the skin must be

surgicall y r emo v ed within a few hour s by

a doctor f amiliar with this f or m of injur y

or gang r ene may r esult.

• K eep y our body and hands a w ay fr om

pin hole leaks or nozzles that eject

high pr essur e h y draulic fluid.

• Use cardboard or paper to find

h y draulic leaks, nev er use y our hands.

10. Chec k the fluid lev el in the h y draulic tank (refer

to Chec king the Hy draulic Fluid in Operation ,

pag e 17 ) and add fluid to raise the lev el to mark

on dipstic k. Do not o v er fill the tank.

11. R emo v e and store the cylinder loc ks and lo w er

the loader ar ms .

Changing the Hydraulic

Fluid

Chang e the h y draulic fluid yearly .

1. P osition the traction unit on a lev el surface .

2. Raise the loader ar ms and install the cylinder

loc ks .

3. Stop the engine and remo v e the k ey .

4. Place a larg e drain pan under the traction unit

that can hold at least 17 US g allons (67 l).

5. R emo v e the drain plug from the bottom of the

h y draulic tank and allo w the fluid to completely

drain out.

6. Install the drain plug .

7. Fill the h y draulic tank with appro ximately

15 US g allons (57 L) of 10W -30 or 15w40

33

Loading...

Loading...