dir t or other debris from the radiator screen with

compressed air .

Changing the Engine Coolant

Ha v e an A uthorized Ser vice Dealer c hang e the

engine coolant yearly .

If y ou need to add engine coolant, refer to

Chec king, Adding, and Bleeding the Engine

Coolant in Operation , pag e 21 .

Belt Maintenance

Checking the Condition of

the Hydraulic Pump Belt

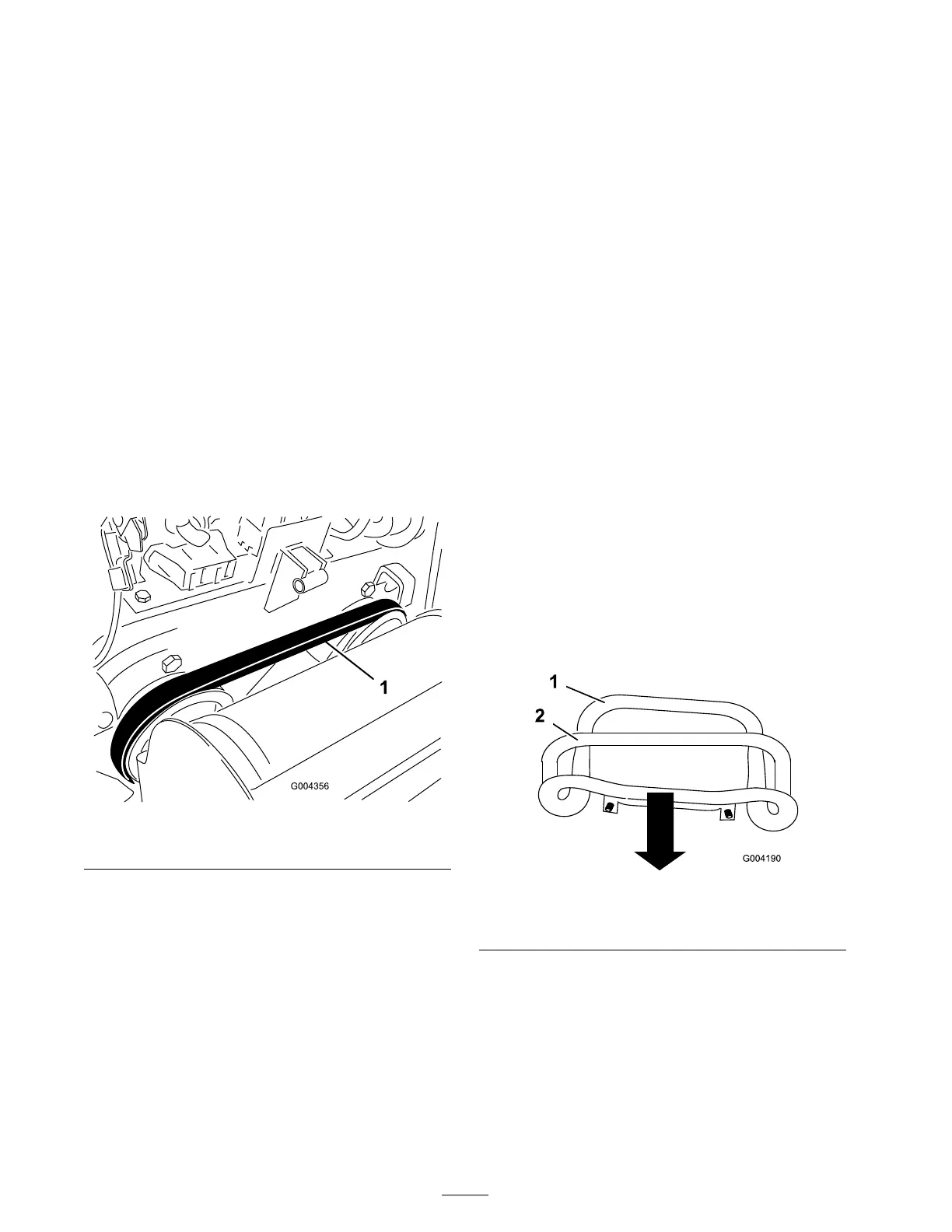

Chec k the condition of the h y draulic pump belt

( Figure 50 ) yearly . Ha v e an A uthorized Ser vice

Dealer re place it if it becomes damag ed or w or n.

Figure 50

1. Hydraulic Pump Belt

Checking the

Alternator/Fan Belt Tension

Chec k and adjust the tension of the alter nator/fan

belt ev er y 100 operating hours . R e place it ev er y

500 operating hours . R efer to the Engine Operator’ s

Manual for instr uctions .

Controls System

Maintenance

T he factor y adjusts the controls before shipping

the traction unit. Ho w ev er , after many hours of

use , y ou ma y need to adjust the traction control

alignment, the neutral position of the traction

control, and the trac king of the traction control in

the full forw ard position.

Important: T o adjust the contr ols pr oper l y ,

complete each pr ocedur e in the order listed.

Adjusting the Traction

Control Alignment

If the traction control bar does not rest flush

and square with the reference bar when in the

full bac kw ard position, immediately complete the

follo wing procedure:

1. P ark the traction unit on a flat surface and

lo w er the loader ar m.

2. Stop the engine and remo v e the k ey .

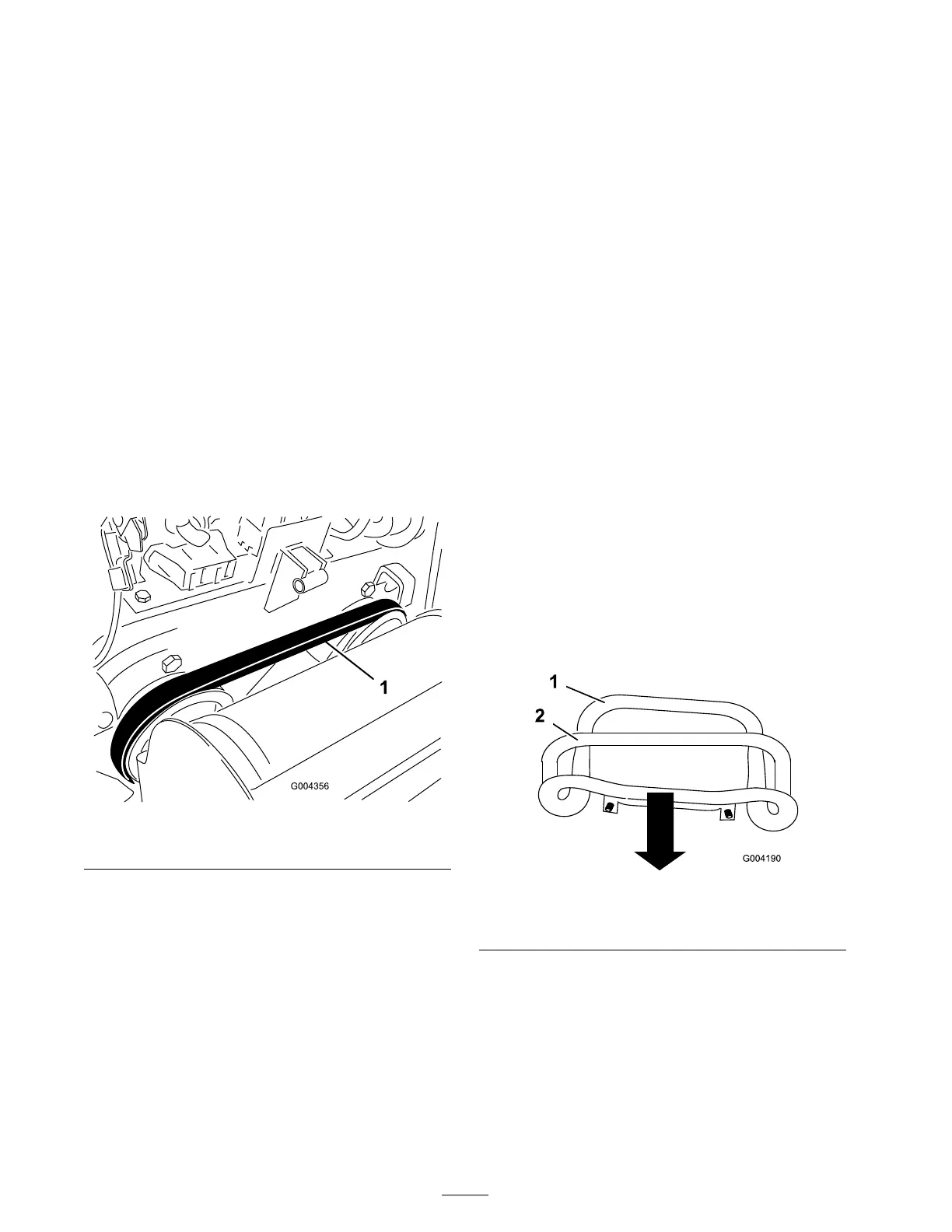

3. Pull straight bac k on the traction control so

the front of the control contacts the reference

bar ( Figure 51 ).

Figure 51

1. Front of the control, out of

alignment

2. Reference bar

4. If the front of the traction control does not

rest square and flush with the reference bar ,

loosen the flang e n ut and bolt in the stem of

the traction control ( Figure 52 ).

42

Loading...

Loading...