ReplacingtheCaster

WheelsandBearings

1.Obtainanewcaster-wheelassembly,cone

bearings,andbearingsealsfromyour

AuthorizedT oroDistributor.

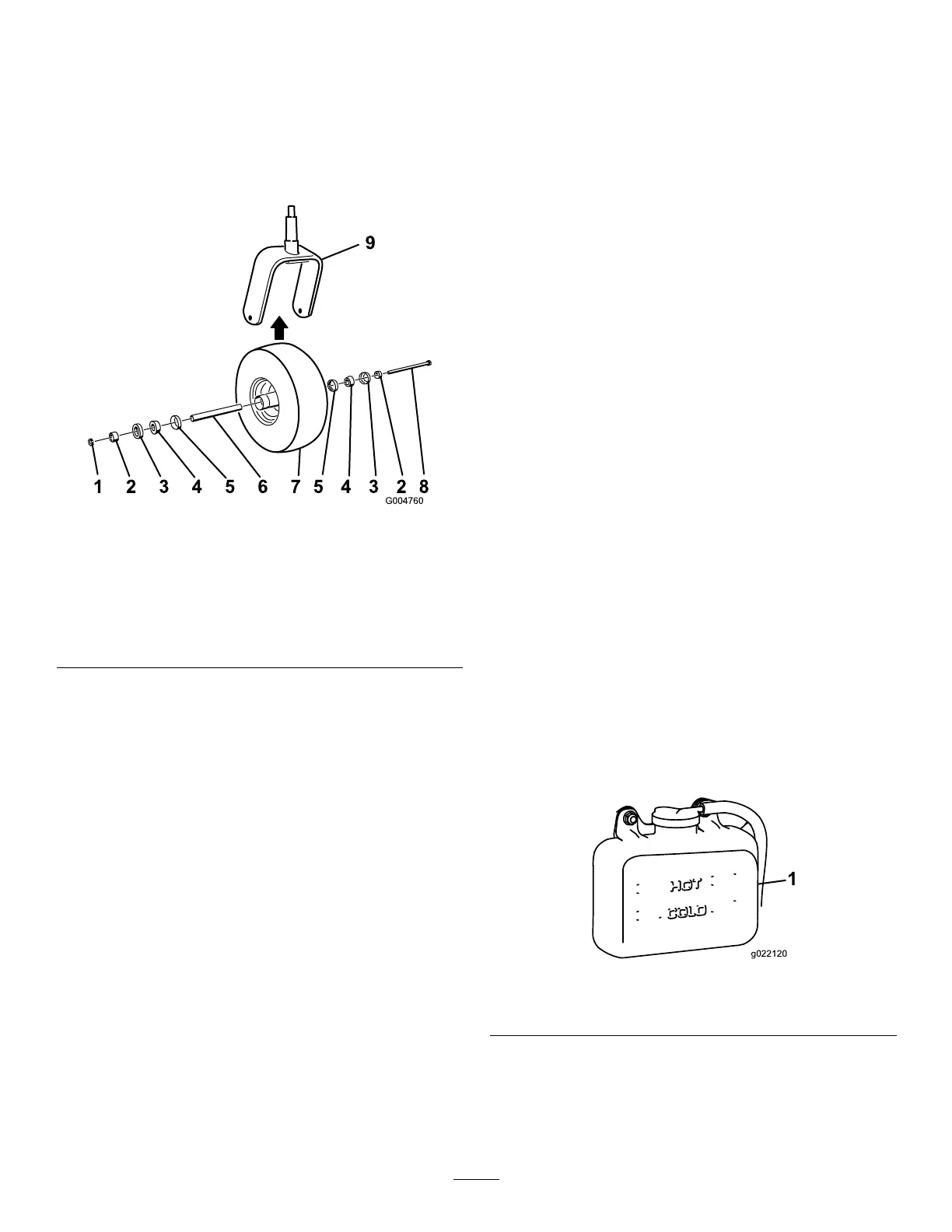

2.Removethelocknutfromthebolt(Figure77).

g004760

Figure77

1.Locknut

6.Spacer

2.Bearingspacer

7.Casterwheel

3.Outerbearingseal

8.Axlebolt

4.Conebearing

9.Casterfork

5.Innerbearingseal

3.Graspthecasterwheelandslidetheboltout

oftheforkorpivotarm.

4.Discardtheoldcasterwheelandbearings.

5.Assemblethecasterwheelbypushingthecone

bearingsandseals,packedwithgrease,intothe

wheelhub,positionedasshowninFigure77.

6.Slidethespacerintothewheelhubthrough

thebearings,captivatingthespacerinsidethe

wheelhubwith2bearingspacers.

Important:Ensurethattheseallipsarenot

foldedinward.

7.Installthecaster-wheelassemblybetweenthe

castorforkandsecureitinplacewiththebolt

andlocknut.

8.Tightenthelocknutuntilthewheelnolonger

spinsfreely,thenbackitoffjustuntilthewheel

spinsfreely.

9.Attachagreaseguntothegreasettingonthe

casterwheelandllitwithNo.2lithiumgrease.

CoolingSystem

Maintenance

CoolingSystemSafety

•Swallowingenginecoolantcancausepoisoning;

keepoutofreachfromchildrenandpets.

•Dischargeofhot,pressurizedcoolantortouching

ahotradiatorandsurroundingpartscancause

severeburns.

–Alwaysallowtheenginetocoolatleast15

minutesbeforeremovingtheradiatorcap.

–Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

•Donotoperatethemachinewithoutthecovers

inplace.

•Keepyourngers,handsandclothingclearof

rotatingfananddrivebelt.

•Shutofftheengineandremovethekeybefore

performingmaintenance.

CheckingtheCooling

System

ServiceInterval:Beforeeachuseordaily

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethyleneglycolantifreeze.The

capacityofthecoolingsystemis7.5L(6USqt).

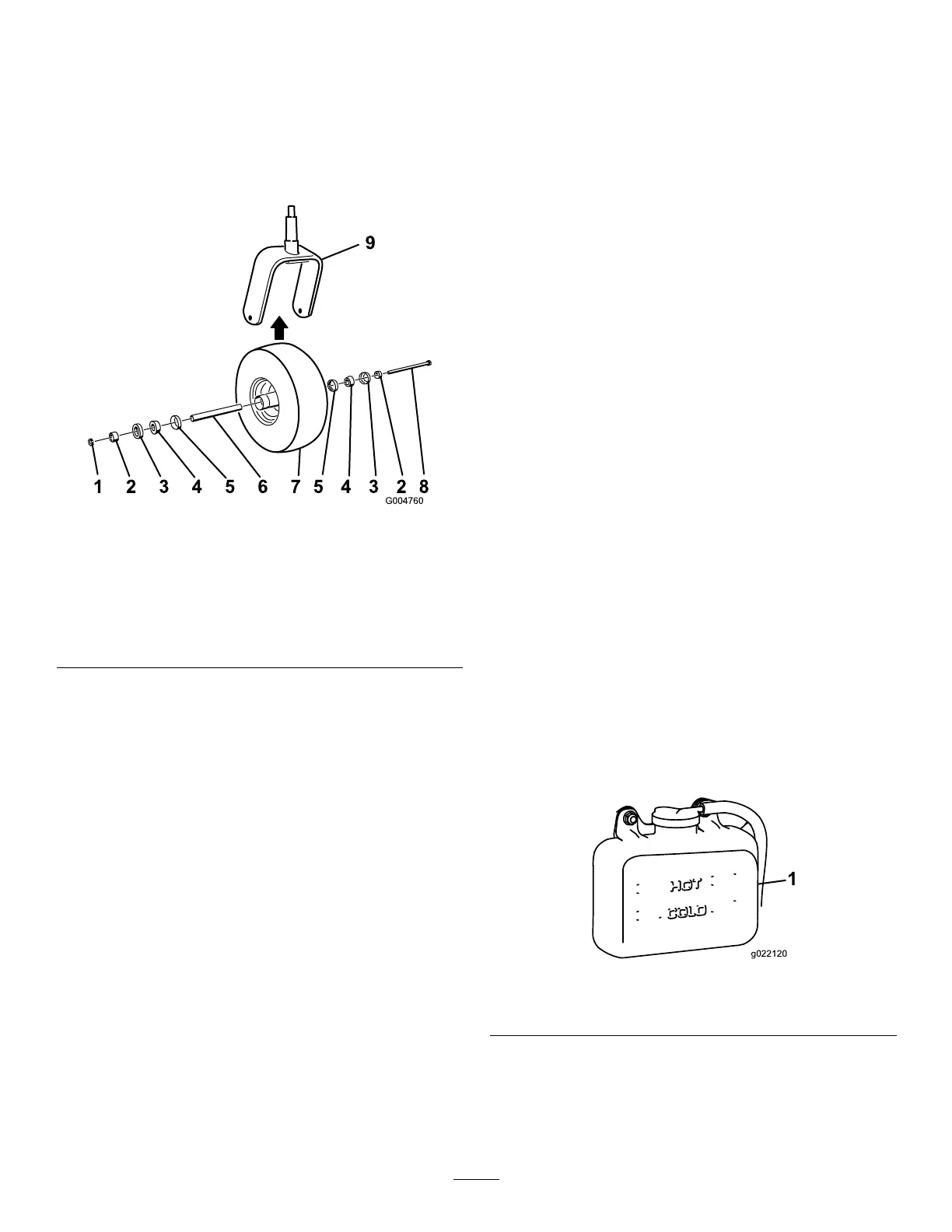

1.Checkthelevelofthecoolantintheexpansion

tank(Figure78).

Note:Thecoolantlevelshouldbebetweenthe

marksonthesideofthetank.

g022120

Figure78

1.Expansiontank

2.Ifcoolantlevelislow,removetheexpansion-tank

capandreplenishthesystem.

Important:Donotoverll.

3.Installtheexpansion-tankcap.

53

Loading...

Loading...