6.

3.

3.

5.

Specifications

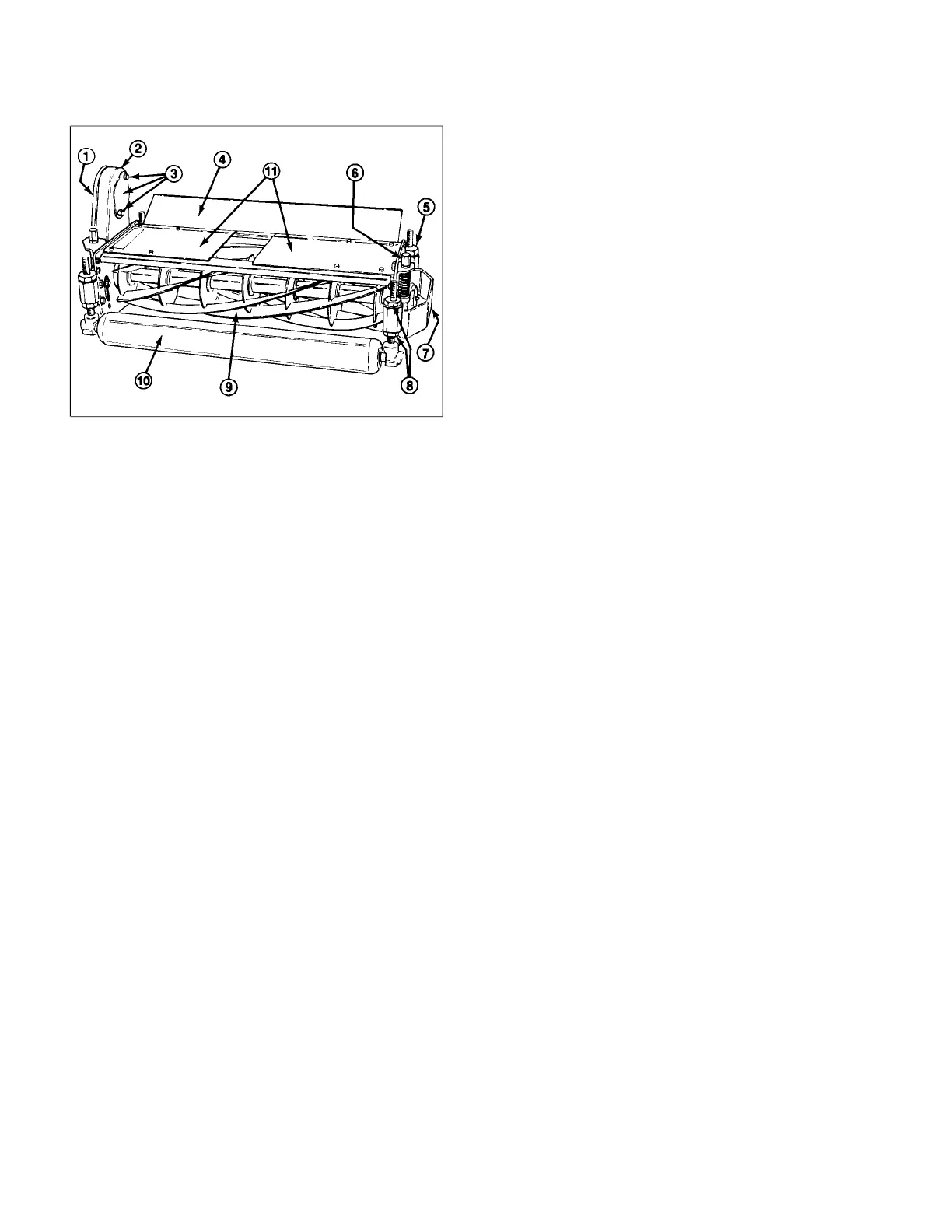

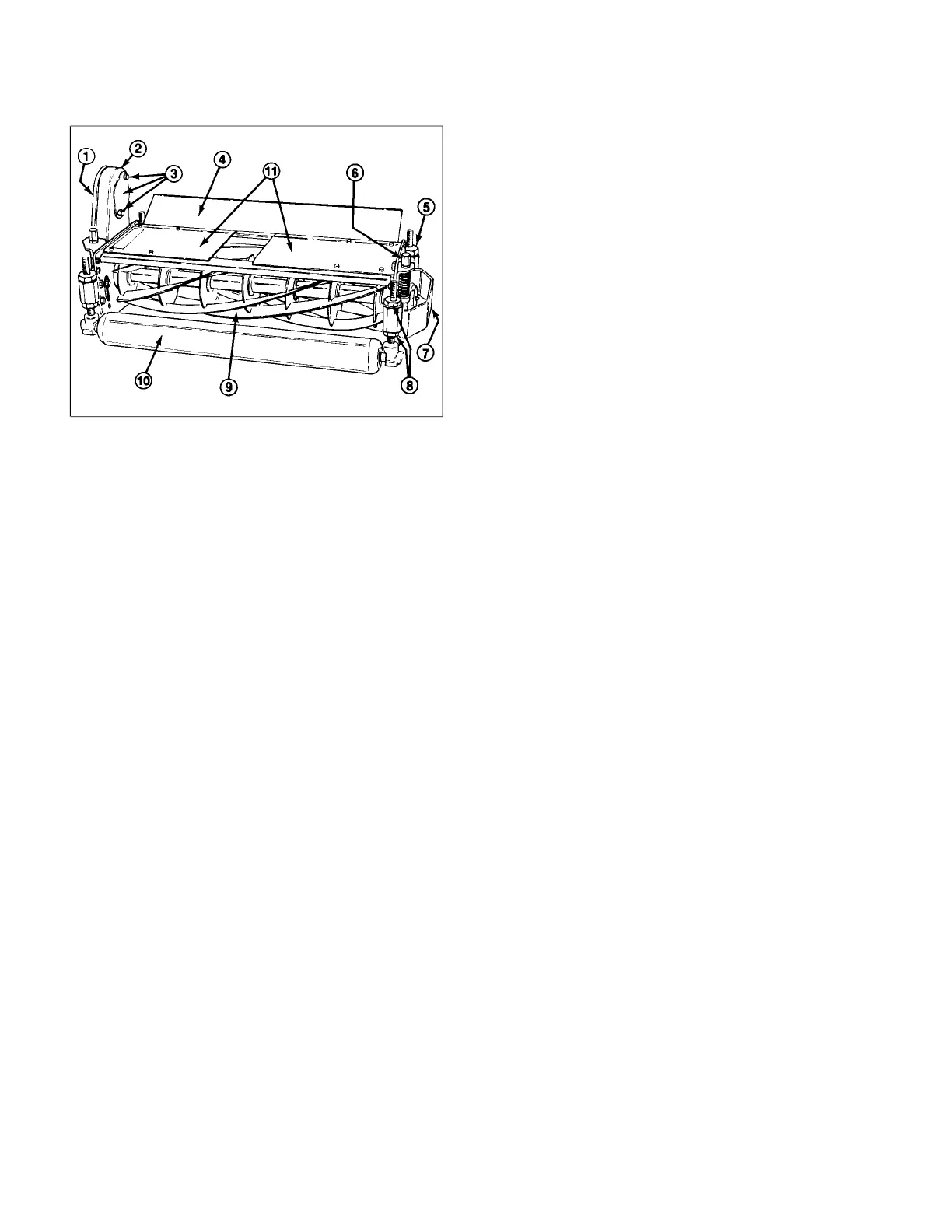

Figure 1

1. Drive housing cover 6. Reel to bedknife

2. Drive housing adjusting assembly

3. Reel motor fasteners, 7. Guard

drive plate shield and 8. Cone nut

shipping cover 9. Reel assembly

4. Grass deflector 10. Front roller (optional)

5. Rear roller adjusting 11. Top covers

assembly

Construction: Welded steel frame and reel with heavy

duty, self-aligning ball bearings. Heavy duty steel rear

roller with tapered roller bearings. Rear roller and bed-

bar are isolated and mounted in rubber bushings for

quiet, vibration-free operation. Adjustable deflector

shields are standard. Stainless steel components are

used at key points for added durability.

Reel Configuration: Th

e 5, 7 and 11 blade heavy duty

welded reels all have 8 in. (20.3 cm) diameters and are

29-3/4 in. (75.5 cm) wide.

Bedknife/Bedbar Assembly: A

replaceable, single

edged, alloy steel bedbar is induction hardened. It’s

fastened with steel screws to a precision ground surface

on the high strength, fabricated steel bedbar. The

stress-relieved machined bedbar is mounted with four

(4) vibration isolation bushings.

Bedknife to Reel Adjustment: T

wo lockable lead

screw adjusters at each side of the frame adjust the reel

to bedknife contact.

Rear Roller: 3-1/2 i

n. (89 mm) diameter steel roller has

greaseable tapered roller bearings. A double lip oil seal

and wear sleeve isolates grit and moisture from the

bearings.

Height-of-Cut: 5

Blade - 1 to 3 in. (25 to 76 mm). 7

Blade - 1/2 to 1-3/4 in. (9.5 to 45 mm). 1 1 Blade - 3/8

to 3/4 in. (9.5 to 19 mm).

Height-of-Cut Adjustment: Quick

adjustment and

positive locking is provided by locking type cone nuts.

Gauge marks of 1/4 in. (6.3 mm) are provided as a

reference for easy changes of height-of-cut.

Clip (variable to match cutting conditions):

5 Blade Cutting Unit: .176 in. per mph

(.

352 in. at 2 mph - 1.32 in. at 7.5 mph)

7 Blade Cutting Unit: .1 26 in. per

(.

252 in. at 2 mph - .945 in. at 7.5 mph)

11 Blade Cutting Unit: .080 in. per mph

(.16 in. at 2 mph - .600 in. at 7.5 mph)

Lubrication: Easily accessible grease fittings for bear-

ings and all major pivot points.

Drive: The reel drive motor turns a maintenance-free

cog belt which drives the reel. Drive pulley and cog belt

are encased in a drive housing for safety and protection

from contamination.

Grass Deflector Shields: Full

y Adjustable.

Specifications Pa

ge 7 - 2 Reelmaster

®

335-D

Loading...

Loading...