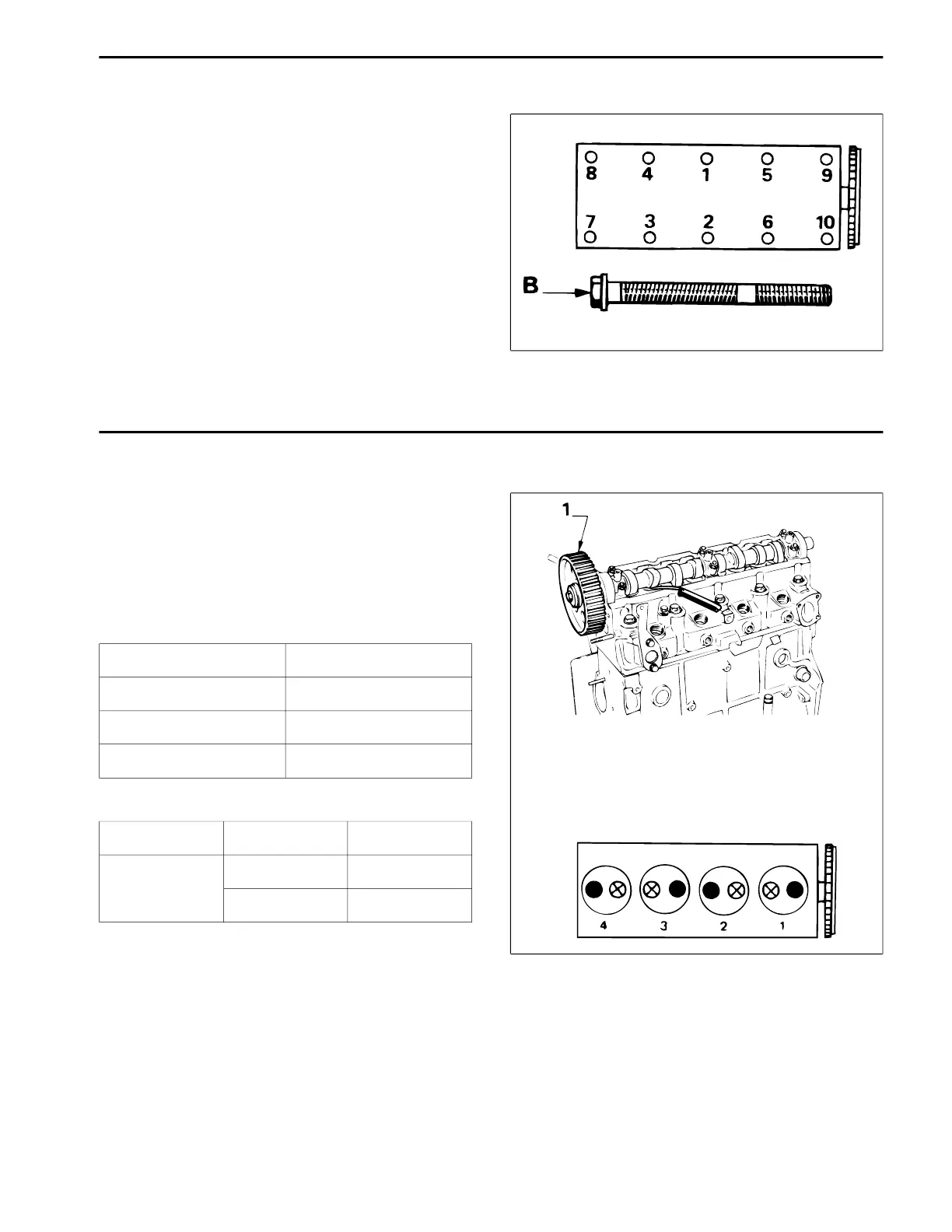

Cylinder Head Tightening

1. Install new washers on the bolts.

2. Pre-tighten the bolts in the order shown (Fig. 84) to a

t

orque of 30 Nm (22 ft-lb).

3. Tighten the bolts in the order shown to a torque of

70 Nm

52 ft-lb).

4. Tighten each bolt in the order shown an additional

120° ± 2°.

NOTE: The special cylinder head bolts (Item B) do not

require re-tightening. The bolts can be removed and

re-installed 5 times before replacing with new bolts.

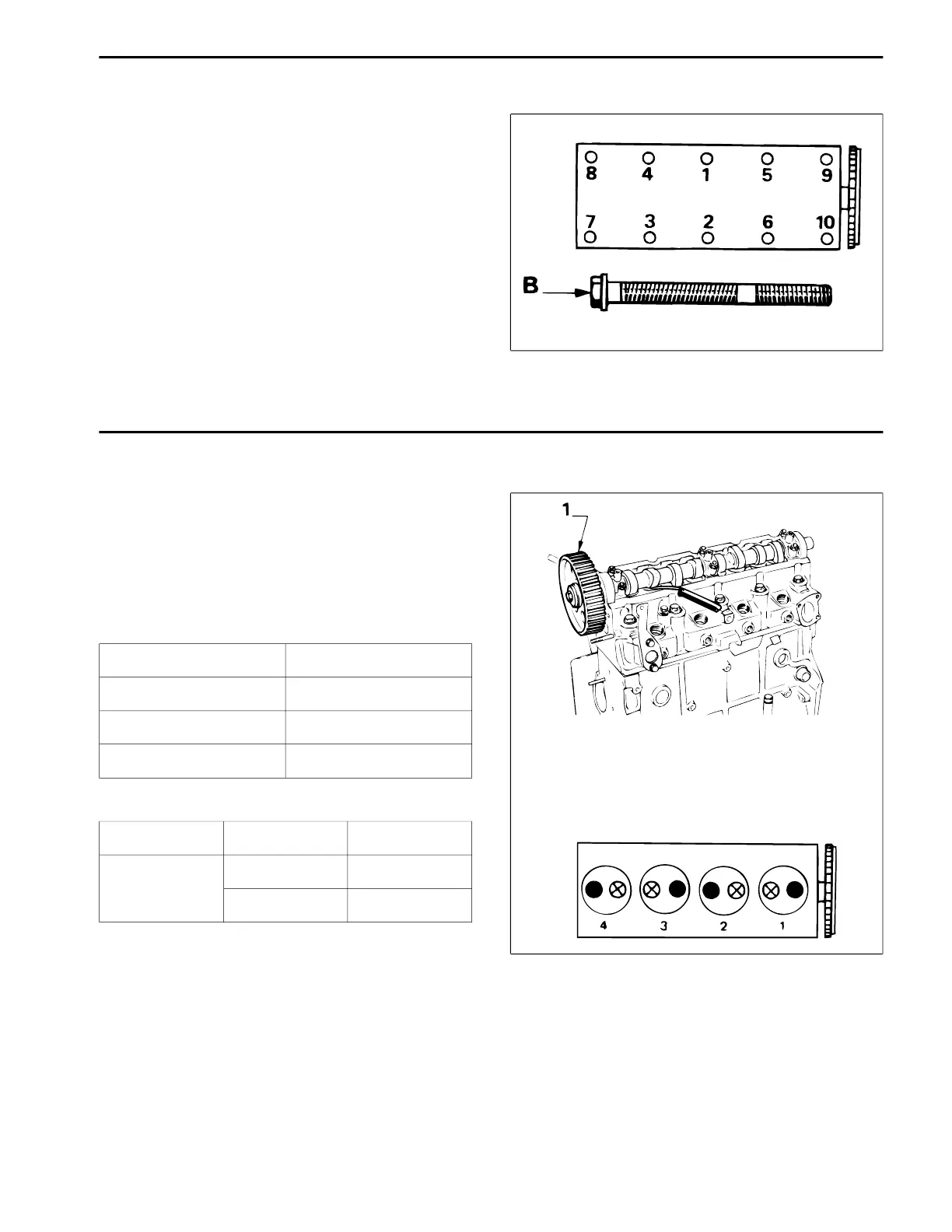

Valve Clearance Adjustment

NOTE: If all valve parts are re-installed in their original

location it should not be necessary to adjust valve

clearance, unless the head has been machined or val-

ves ground.

1. Install the camshaft gear. (Fig. 85, Item 1).

2. Check the valve clearance:

Units: mm

Running Clearance

Inlet 0.15

Exhaust 0.30

Tolerance ± 0.

04

Set “on the rock” Inlet 4, Exhaust 4 Inlet 1, Exhaust 1

Check Inlet 1, Exhaust 1 Inlet 4, Exhaust 4

Inlet 2, Exhaust 3 Inlet 3, Exhaust 2

Figure 84

Figure 85

Reelmaster 335-D/3500-D Page 3 - 57

Rev. B

Engine

Loading...

Loading...