Cylinder Head Gasket Selection

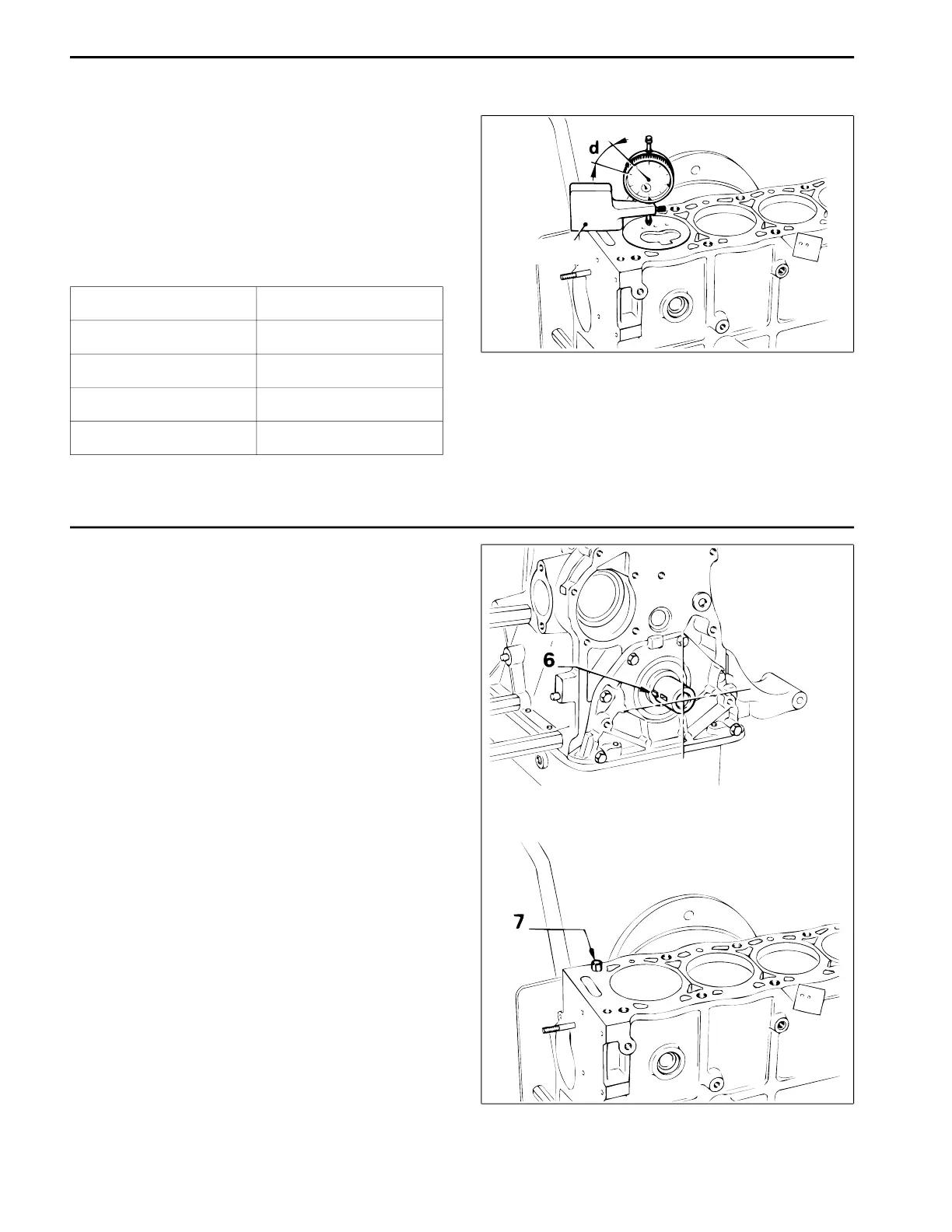

1. Install the dial indicator on support TOR 80110 H and

zero it on a surface plate.

2. Turn the crankshaft and measure the protrusion of

each piston at TDC.

3. Note the maximum protrusion (Fig. 82, Item d).

4. Select a cylinder head gasket of suitable thickness.

Units: mm

Piston protrusion (d) Thickness identification

0.56 to 0.71 2 notches

0.71 to 0.75 3 notches

0.75 to 0.79 4 notches

0.79 to 0.83 5 notches

TOR 80110H

Figure 82

Cylinder Head Installation

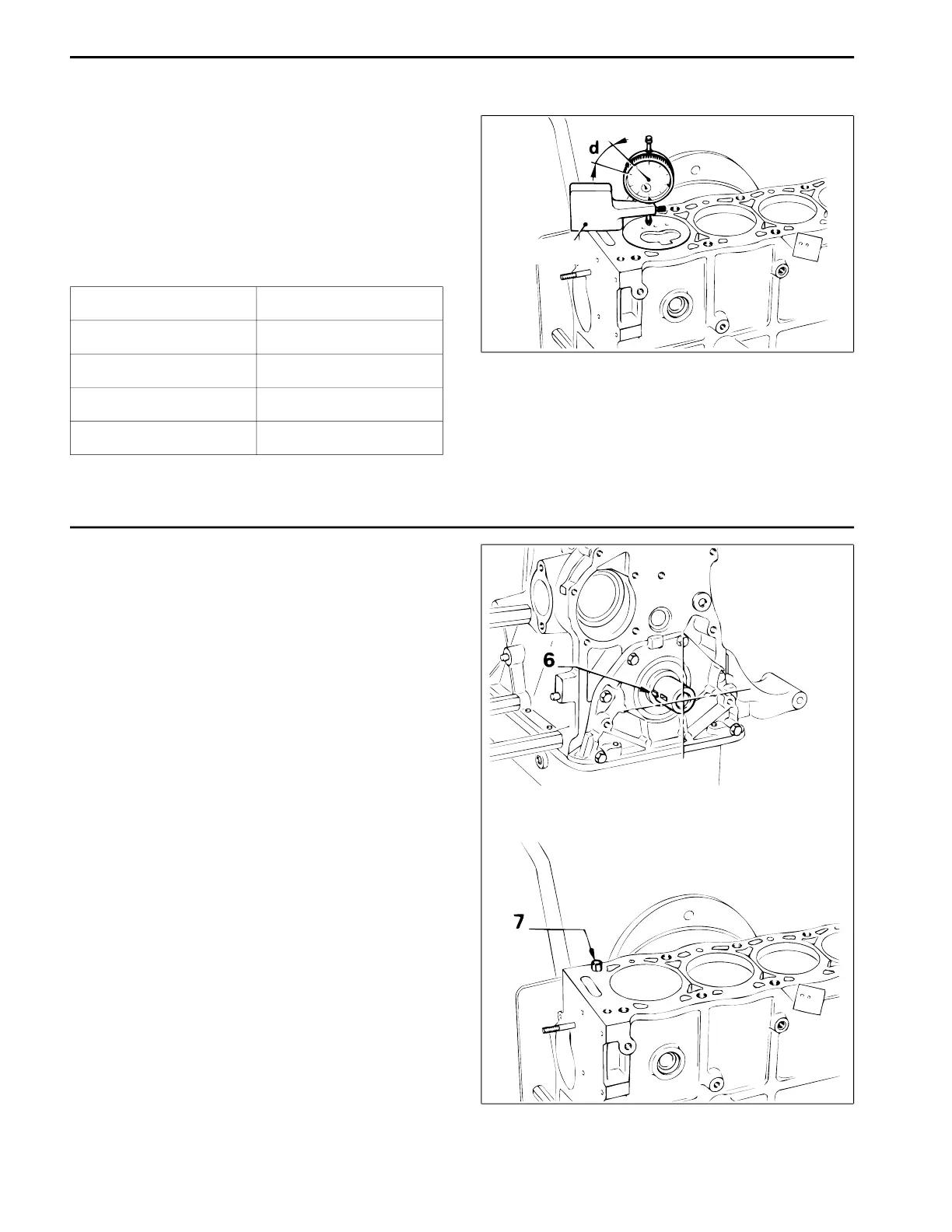

1. Turn the crankshaft to put the pistons at mid-stroke

with damper pulley key (Fig. 83, Item 6) at the 9 o’clock

position.

2. Clean the tapped holes in the cylinder block (12 x 150

t

hread).

3. Install the centralizing dowel (Item 7).

4. Install a new head gasket (dry).

5. Install the cylinder head.

6. Carefully clean the threads of the cylinder head bolts

wit

h a brush.

7. Coat the bolt threads and washer contact faces with

M

OLYKOTE G RAPID.

Figure 83

Engine Page 3 - 56

Rev

. B

Reelmaster 335-D/3500-D

Loading...

Loading...