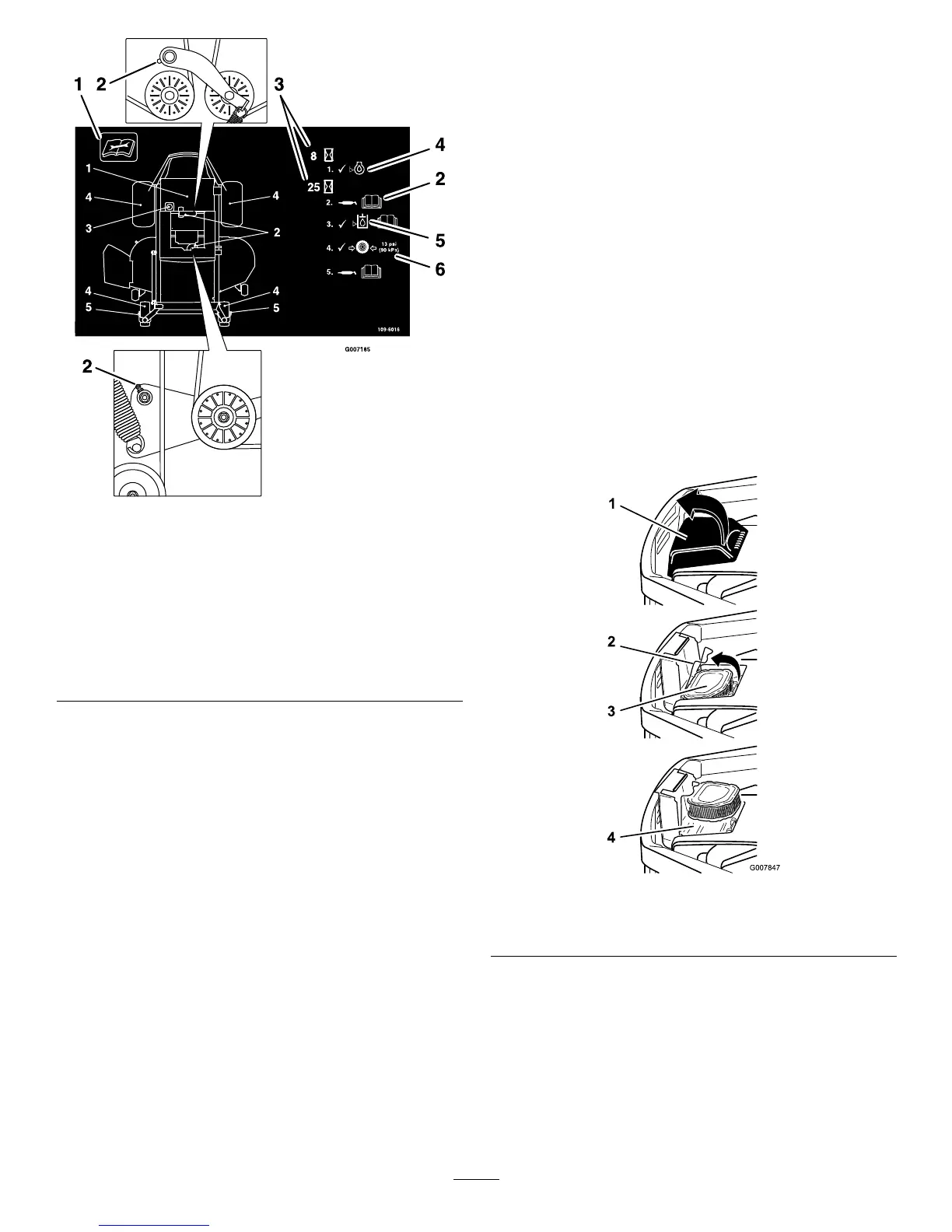

Figure23

Locatedonthebackoftheseat.

1.Readtheinstructions

beforeservicingor

performingmaintenance

4.Checkoillevel.

2.Greaseidlerpivots.5.Checkhydraulicoillevel

andrefertoOperator’s

manualforfurther

instructions.

3.Timeinterval.

6.Checktirepressure.

4.Connectagreaseguntoeachtting(Figure22and

Figure23).Pumpgreaseintothettingsuntilgrease

beginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checkthe

aircleanerfordirty,looseordamaged

parts.

Thisengineisequippedwithareplaceable,highdensity

paperaircleanerwithafoamprecleanersurrounding

it.Checktheaircleanerdailyorbeforestartingthe

engine.Checkforabuildupofdirtanddebrisaround

theaircleanersystem.Keepthisareaclean.Alsocheck

forlooseordamagedcomponents.Replaceallbentor

damagedaircleanercomponents.

Note:Operatingtheenginewithlooseordamagedair

cleanercomponentscouldallowunlteredairintothe

enginecausingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

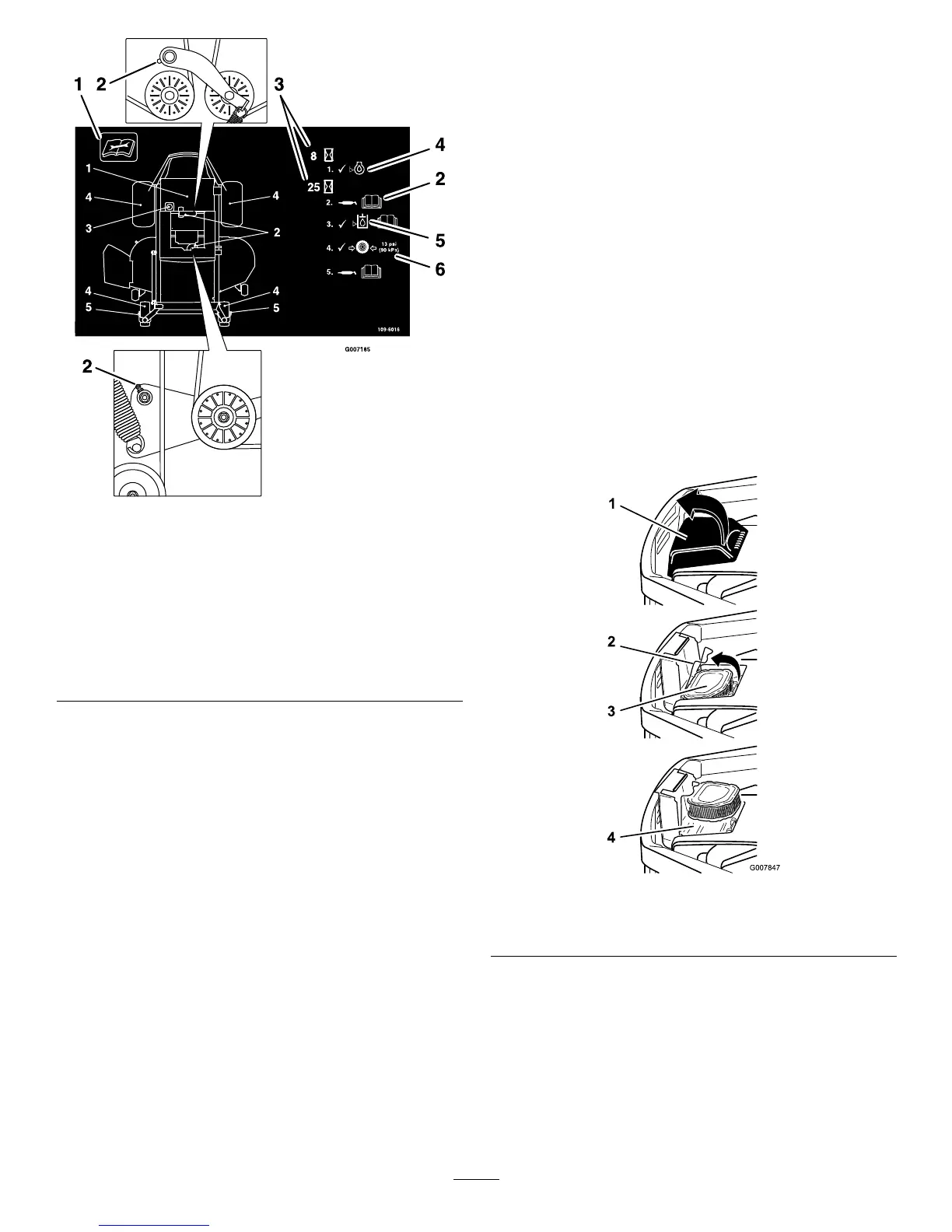

Figure24

1.Aircleanercover3.Paperelement

2.Aircleanerlatch4.Aircleanerbase

ServicingPrecleanerElement

ServiceInterval:Every25hours—Servicethe

precleanerelement.(moreoften

underextremelydusty,dirty

conditions)

Every100hours—Replacethe

precleanerelement.(moreoften

28

Loading...

Loading...