Loading...

Loading...

Do you have a question about the Toshiba MMY-MUP2401HT8P-A and is the answer not in the manual?

| Brand | Toshiba |

|---|---|

| Model | MMY-MUP2401HT8P-A |

| Category | Air Conditioner |

| Language | English |

Lists parts and ratings for 50Hz outdoor units.

Details components within the inverter assembly.

Visual representation of parts placement in outdoor units.

Visual representation of parts within the inverter assembly.

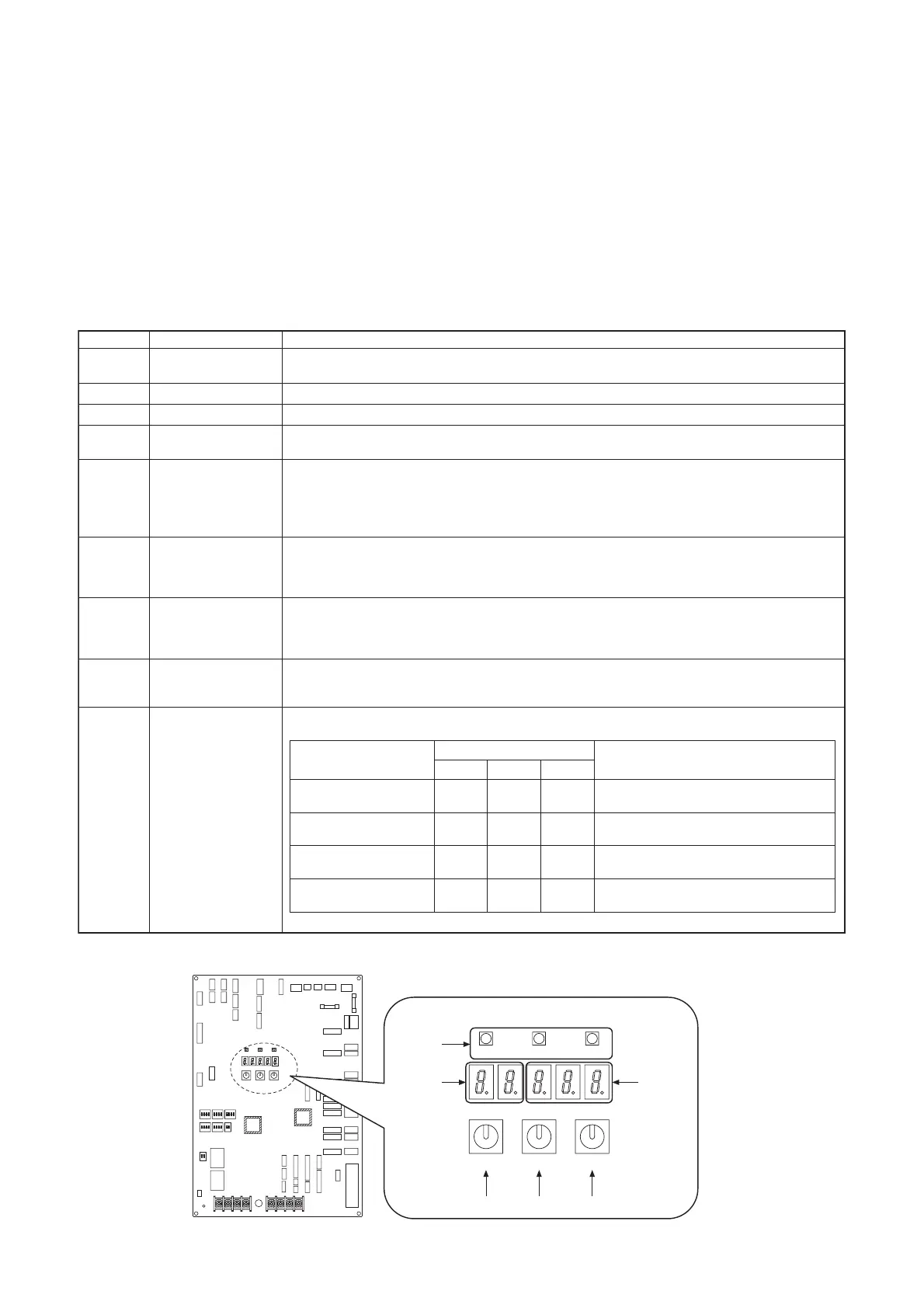

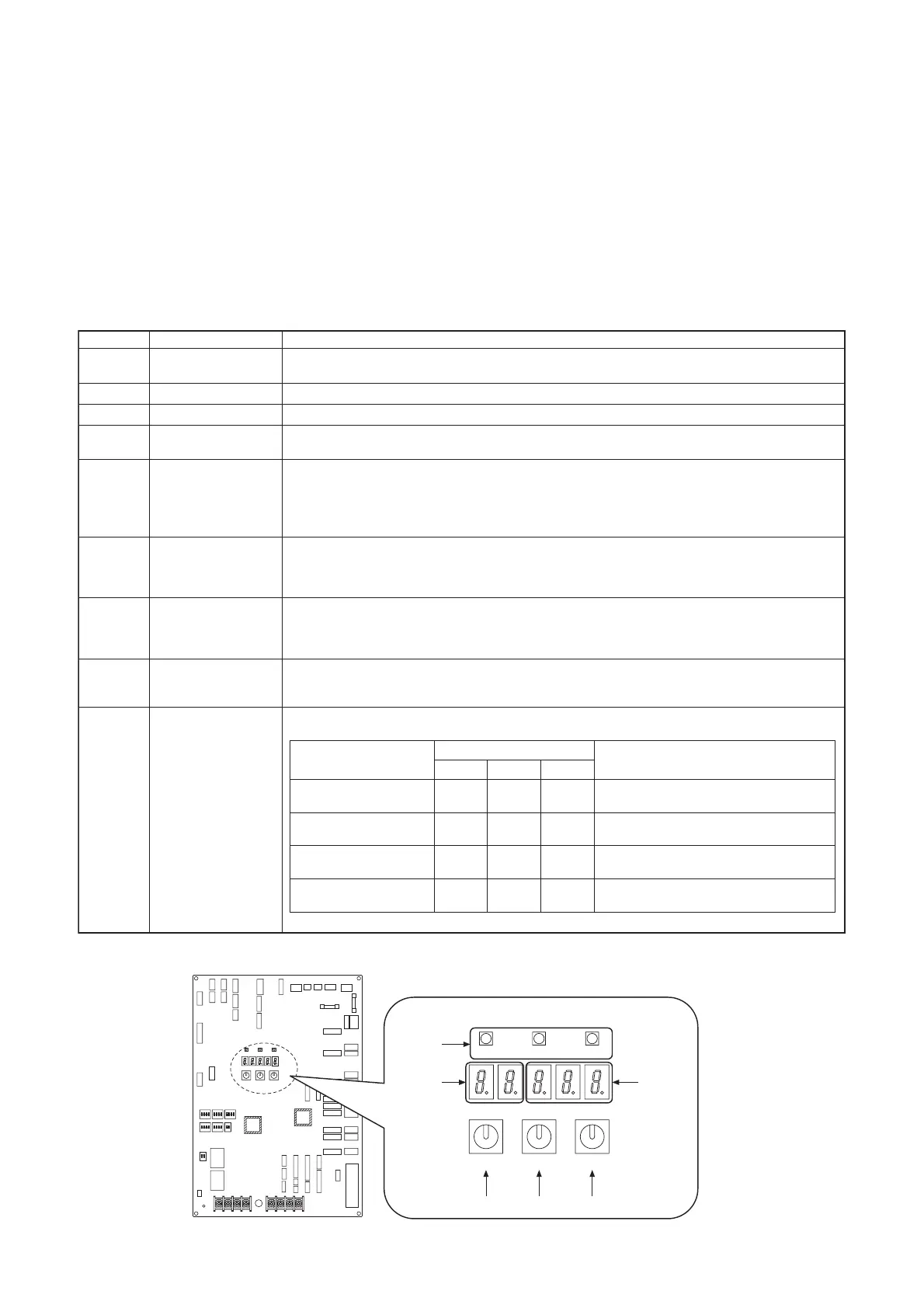

Explains the layout of the outdoor inverter circuit board.

Illustrates the refrigerant flow during cooling operation.

Illustrates the refrigerant flow during single defrost operation.

Illustrates the refrigerant flow during heating operation.

Illustrates refrigerant flow for individual defrost operations.

Shows refrigerant flow during automatic emergency cooling.

Shows refrigerant flow during automatic emergency heating.

Illustrates refrigerant flow during the reclaim process.

Details the control functions of the outdoor unit.

Lists specifications for optional indoor P.C. board connectors.

Describes how to perform test operations for indoor units.

Explains how to set indoor unit function codes via remote controller.

Guides setting outdoor unit function codes using switches or remote controller.

Details control systems using remote location ON/OFF boxes.

Explains applied controls for outdoor units based on settings.

Explains how notice codes are displayed and managed.

Describes how systems cooperate to manage defrosting timing.

Details how to set night operation for reduced sound levels.

Provides an overview and steps for test operations.

Lists essential checks before starting test operations.

Steps to check the system after main power is turned on.

Procedures for setting system addresses.

Addresses issues encountered during test operations.

Procedures to check system operation after test run.

Provides functions for service support and troubleshooting.

Information on using the Wave Tool Advance application.

Provides an overview of troubleshooting procedures and tools.

Explains how to use check codes for troubleshooting.

Troubleshooting based on remote controller displays and history.

Lists check codes and locations for troubleshooting.

Flowcharts for diagnosing specific check codes.

Explains the function and usage of the 7-segment display.

How to check compressor oil levels using the display.

Table detailing DIP switch and function settings.

Identifies check codes related to refrigerant or oil circuit issues.

Important notes and considerations for backup operations.

Procedure for setting compressor backup operation.

Procedures for setting outdoor unit backup operation.

Specific backup operation settings for cooling season.

Overview of the automatic backup operation function.

Methods for reclaiming refrigerant from faulty outdoor units.

Guides system operation while a unit is under repair.

Steps to follow after completing repairs, including vacuuming.

Outlines the general steps for compressor replacement.

Detailed steps for replacing compressors and adjusting oil.

Diagnosing causes of compressor oil shortage.

Lists service parts for outdoor PC boards and inverters.

Exploded diagram and parts list for 8-14HP outdoor units.

Exploded diagram and parts list for 14A-20HP outdoor units.

Exploded diagram and parts list for 22-24HP outdoor units.