Pressure 98

N

Alternator adjusting bolt

1

ENGINE

TUNE-UP

V

BELT TENSION INSPECTION AND

ADJUSTMENT

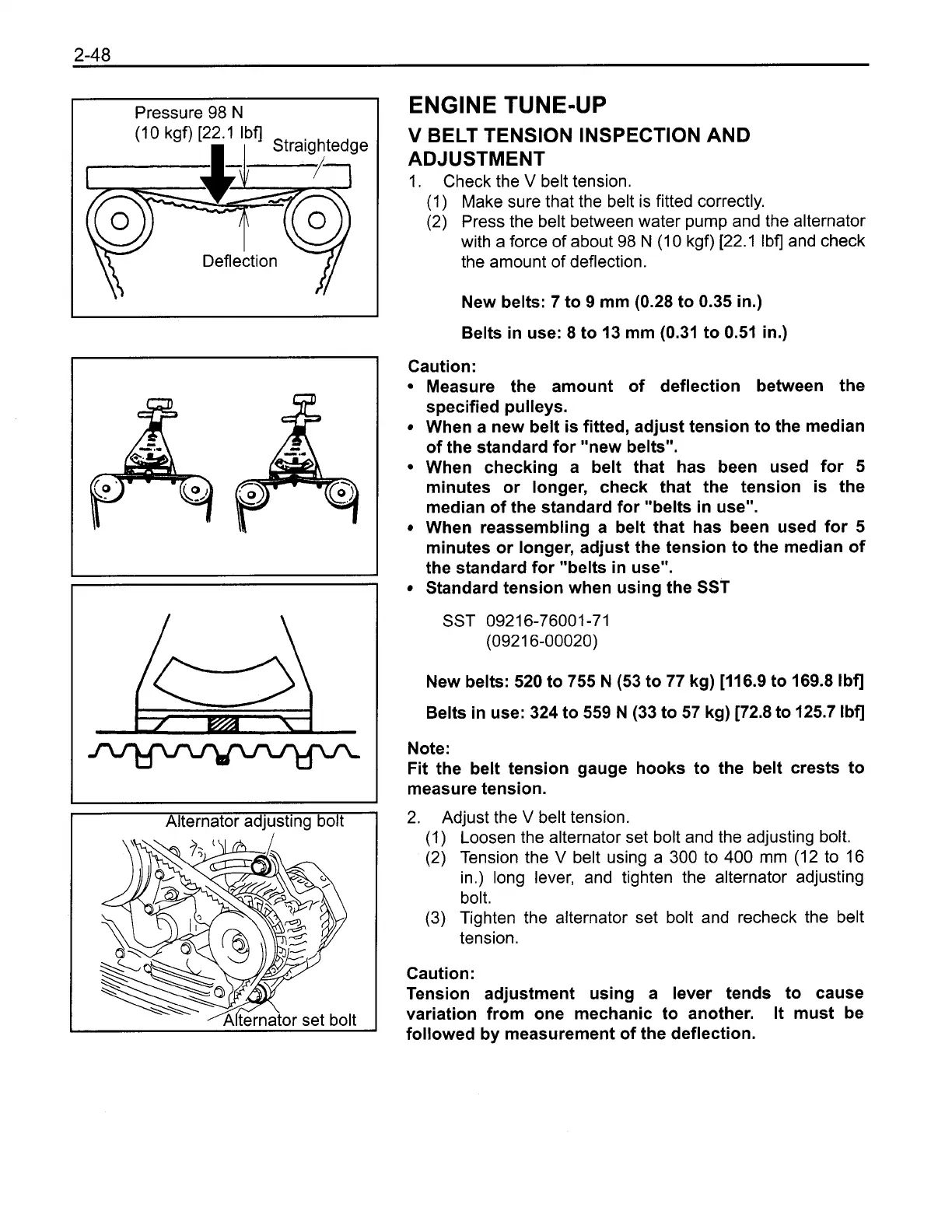

1. Check the

V

belt tension.

(1) Make sure that the belt is fitted correctly.

(2) Press the belt between water pump and the alternator

with a force of about 98

N

(10 kgf) [22.1 Ibfl and check

the amount of deflection.

New belts:

7

to

9

mm

(0.28

to

0.35

in.)

Belts in use:

8

to

13

mm

(0.31

to

0.51

in.)

Caution:

Measure the amount of deflection between the

specified pulleys.

When a new belt is fitted, adjust tension to the median

of the standard for "new belts".

When checking a belt that has been used for

5

minutes or longer, check that the tension is the

median of the standard for "belts in use".

When reassembling a belt that has been used for

5

minutes or longer, adjust the tension to the median of

the standard for "belts in use".

Standard tension when using the SST

SST

092 16-7600 4-71

(0921 6-00020)

New belts:

520

to

755

N

(53

to

77

kg)

[116.9

to

169.8

Ibfl

Belts in use:

324

to

559

N

(33

to

57

kg)

[72.8

to

125.7

Ibfl

Note:

Fit the belt tension gauge hooks to the belt crests to

measure tension.

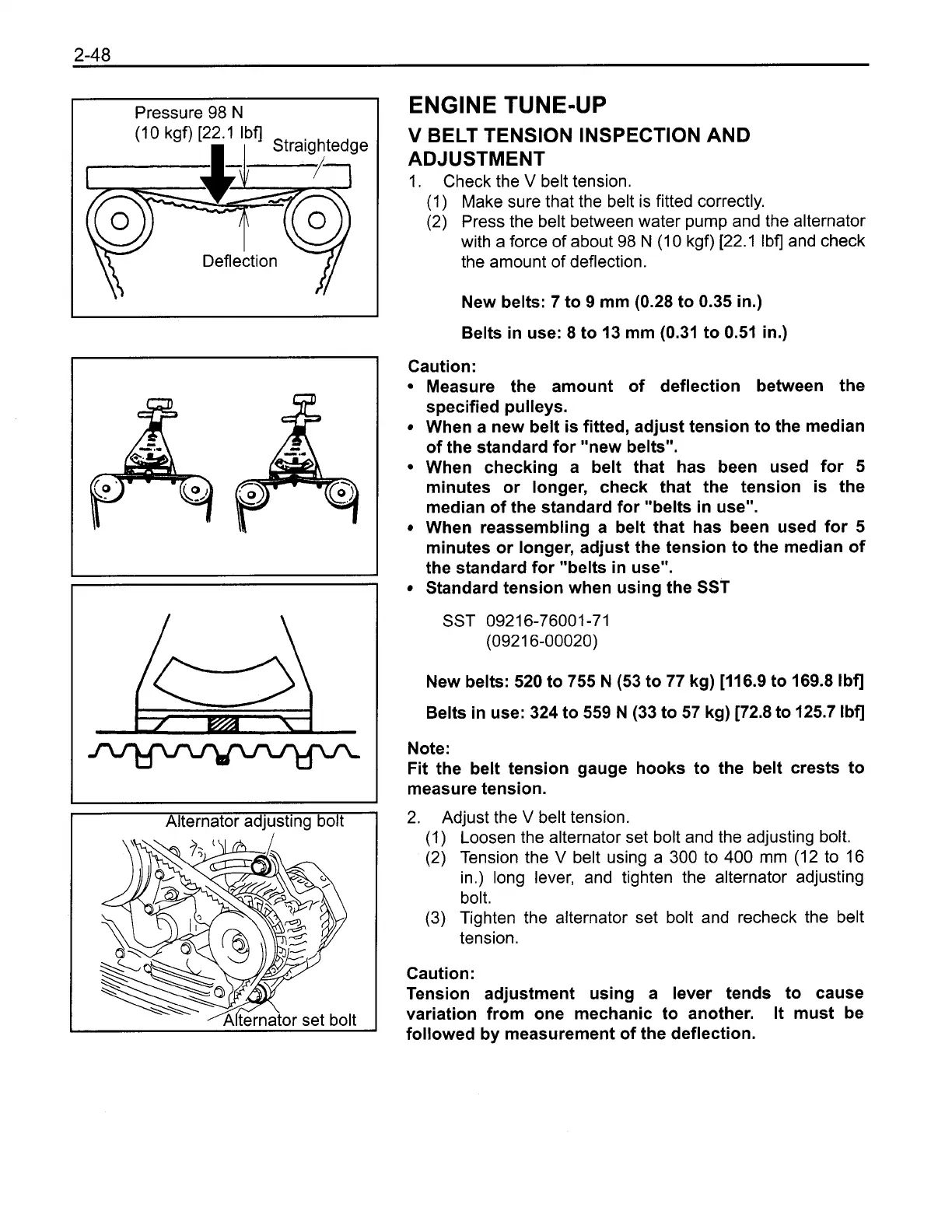

2. Adjust the

V

belt tension.

(1) Loosen the alternator set bolt and the adjusting bolt.

(2) Tension the

V

belt using a 300 to 400 mm (12 to 16

in.) long lever, and tighten the alternator adjusting

bolt.

(3) Tighten the alternator set bolt and recheck the belt

tension.

Caution:

Tension adjustment using a lever tends to cause

variation from one mechanic to another. It must be

followed by measurement of the deflection.

Loading...

Loading...