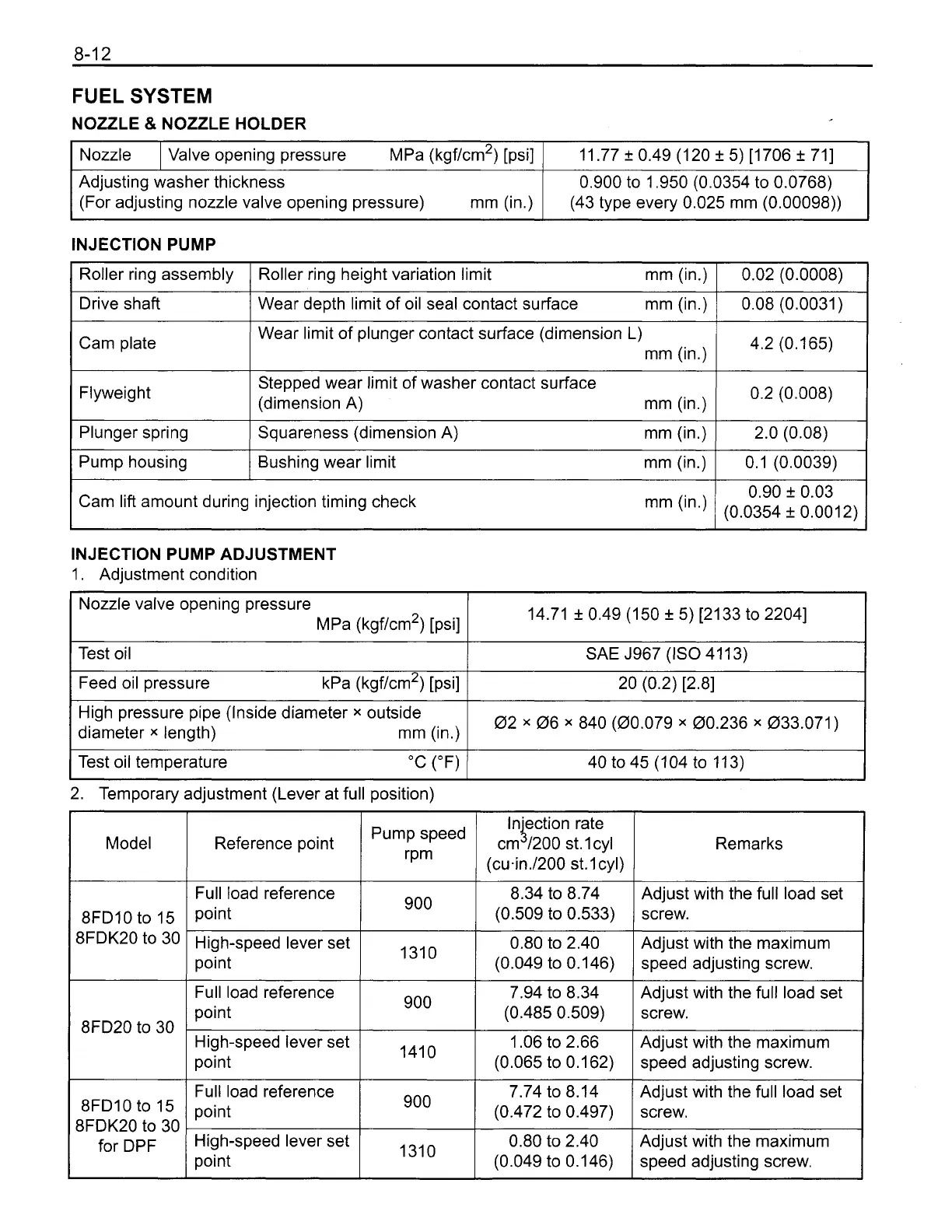

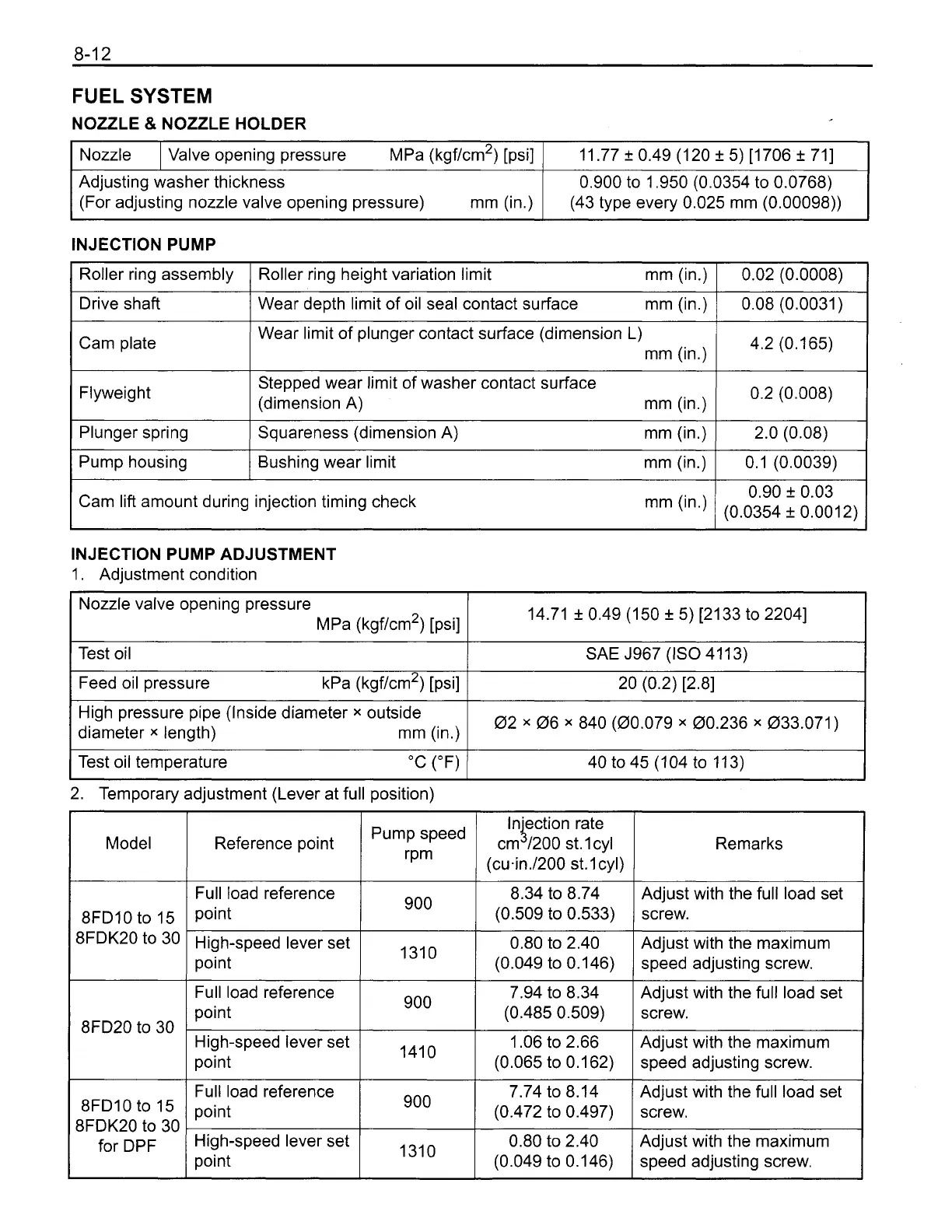

FUEL

SYSTEM

NOZZLE

&

NOZZLE HOLDER

INJECTION PUMP

Nozzle

I

Valve opening pressure MPa (kgf/cm2) [psi]

Adjusting washer thickness

(For adjusting nozzle valve opening pressure) mm (in.)

Roller ring assembly

11.77

f

0.49 (120

f

5) [I706

f

711

0.900 to 1.950 (0.0354 to 0.0768)

(43 type every 0.025 mm (0.00098))

Roller ring height variation limit

--

mm (in.)

Drive shaft Wear depth limit of oil seal contact surface mm (in.)

Cam plate

Flyweight

Wear limit of plunger contact surface (dimension

L)

mm (in.)

Stepped wear limit of washer contact surface

(dimension A) mm (in.)

Plunger spring Squareness (dimension A) mm (in.)

Pump housing Bushing wear limit mm (in.)

Cam lift amount during injection timing check mm (in.)

INJECTION PUMP ADJUSTMENT

1.

Adjustment condition

Nozzle valve opening pressure

MPa (kgf/cm2) [psi]

1

14.71

f

0.49 (150

f

5) [2133 to 22041

I

Test oil

SAE J967 (IS0 41 13)

I

Feed oil pressure

kPa (kgf/cm2) [psi]

I

High pressure pipe (Inside diameter

x

outside

diameter

x

length) mm (in.)

1

02

x

06

x

840 (00.079

x

00.236

x

033.071)

I

Test oil temperature

OC (OF)

I

40 to 45 (1 04 to 11 3)

2. Temporary adjustment (Lever at full position)

In'ection rate

5

cm 1200 st.

I

cyl

(cu.in./200 st.

I

cyl)

Reference point Model

Pump speed

rpm

Remarks

Adjust with the full load set

screw.

Full load reference

point

1

900

High-speed lever set

point

1

1310

Adjust with the maximum

speed adjusting screw.

Adjust with the full load set

screw.

Full load reference

point

Adjust with the maximum

speed adjusting screw.

900

High-speed lever set

point

8FDlO to 15

8FDK20 to 30

for DPF

1410

Full load reference

point

1

900

Adjust with the full load set

screw.

High-speed lever set

point

1

1310

Adjust with the maximum

speed adjusting screw.

Loading...

Loading...