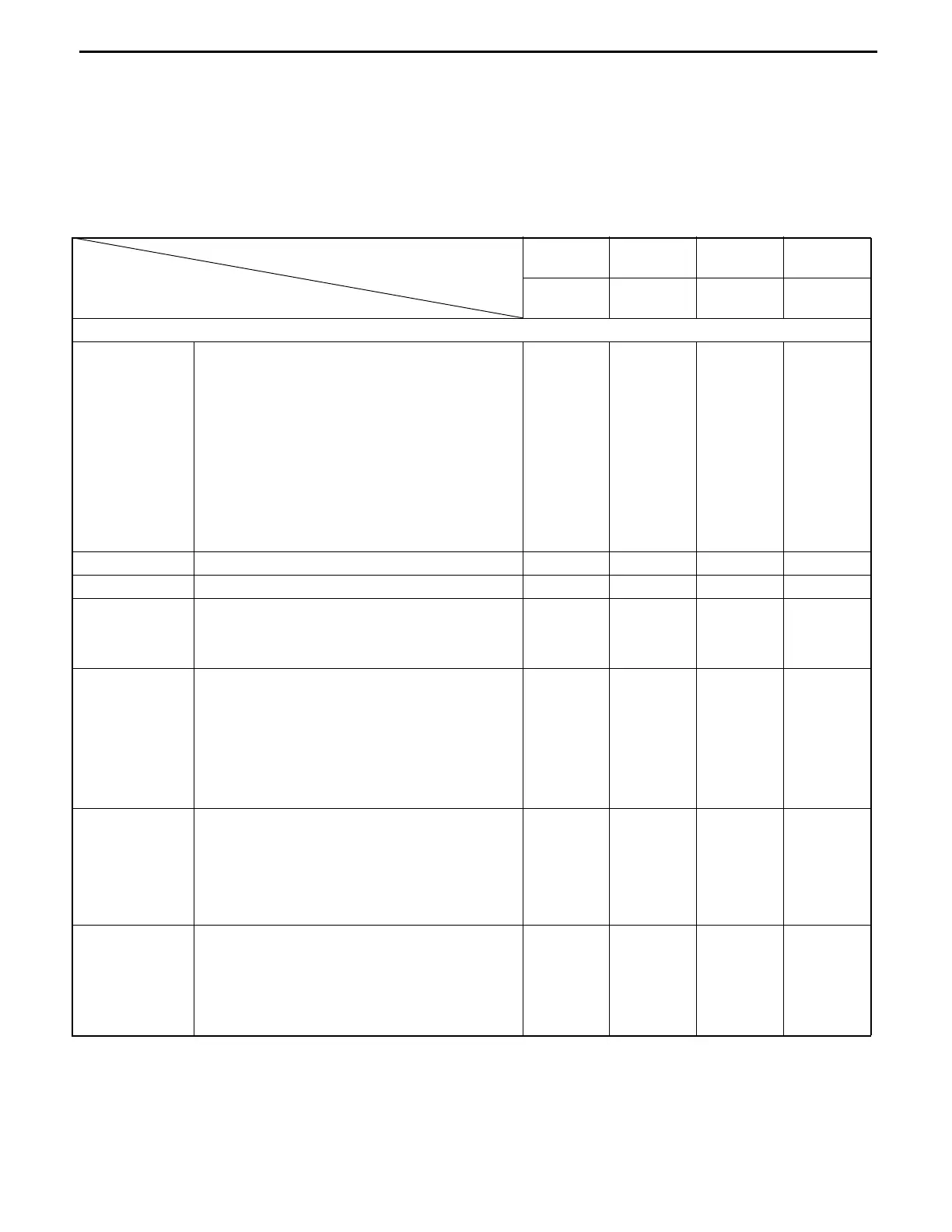

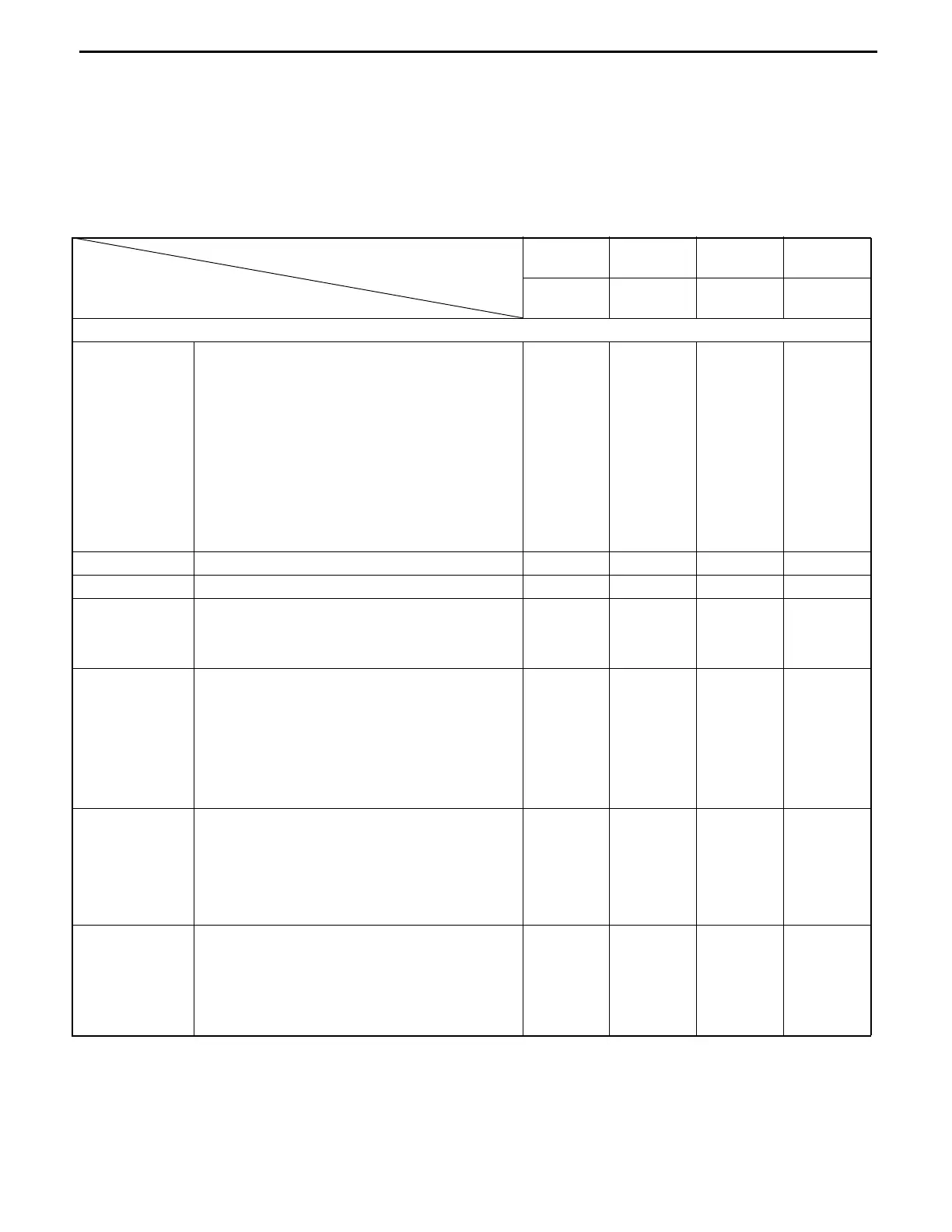

0-21

PERIODIC MAINTENANCE

INSPECTION METHOD

I: Inspection. Repair or replacement if required.

M: Measurement. Repair or adjustment if required.

T: Retightening C: Cleaning L: Lubrication

*: For new vehicle *1: Flaw detector

Inspection Period Every

6 weeks

Every

3 months

Every

6 months

Every

12 months

Item

Every

250 hours

Every

500 hours

Every

1000 hours

Every

2000 hours

ENGINE

Main body

Proper starting and abnormal noise I ←←←

Rotating condition at idling M ←←←

Rotating condition during acceleration M ←←←

Exhaust gas condition I ←←←

Air cleaner element C ←←←

Valve clearance (IDZ-II·2Z) M* M

Compression M

Cylinder head bolt loosening T

Muffler rubber mount I

PCV system Clogging and damage in PCV valve and piping I ←←←

Governor No-load maximum rpm M ←←←

Lubrication

system

Oil leak I ←←←

Oil level I ←←←

Clogging and dirt of oil filter I ←←←

Fuel system

Fuel leak I ←←←

Operation of carburetor link mechanism I ←←←

Dirt and clogging of fuel filter and element I ←←←

Injection timing M ←

Injection nozzle injection pressure and spray status M

Draining of sedimenter I ←

Cooling system

Coolant level in radiator and leak I ←←←

Rubber hose degradation I ←←←

Radiator cap condition I ←←←

Fan belt tension, looseness and damage I ←←←

Radiator rubber mount I

LPG fuel system

Pipe and joint gas leak I ←←←

Pipe and joint damage I ←←←

Regulator tar removal I ←←←

LPG container installation section looseness and

damage

I ←←←

Loading...

Loading...