4.

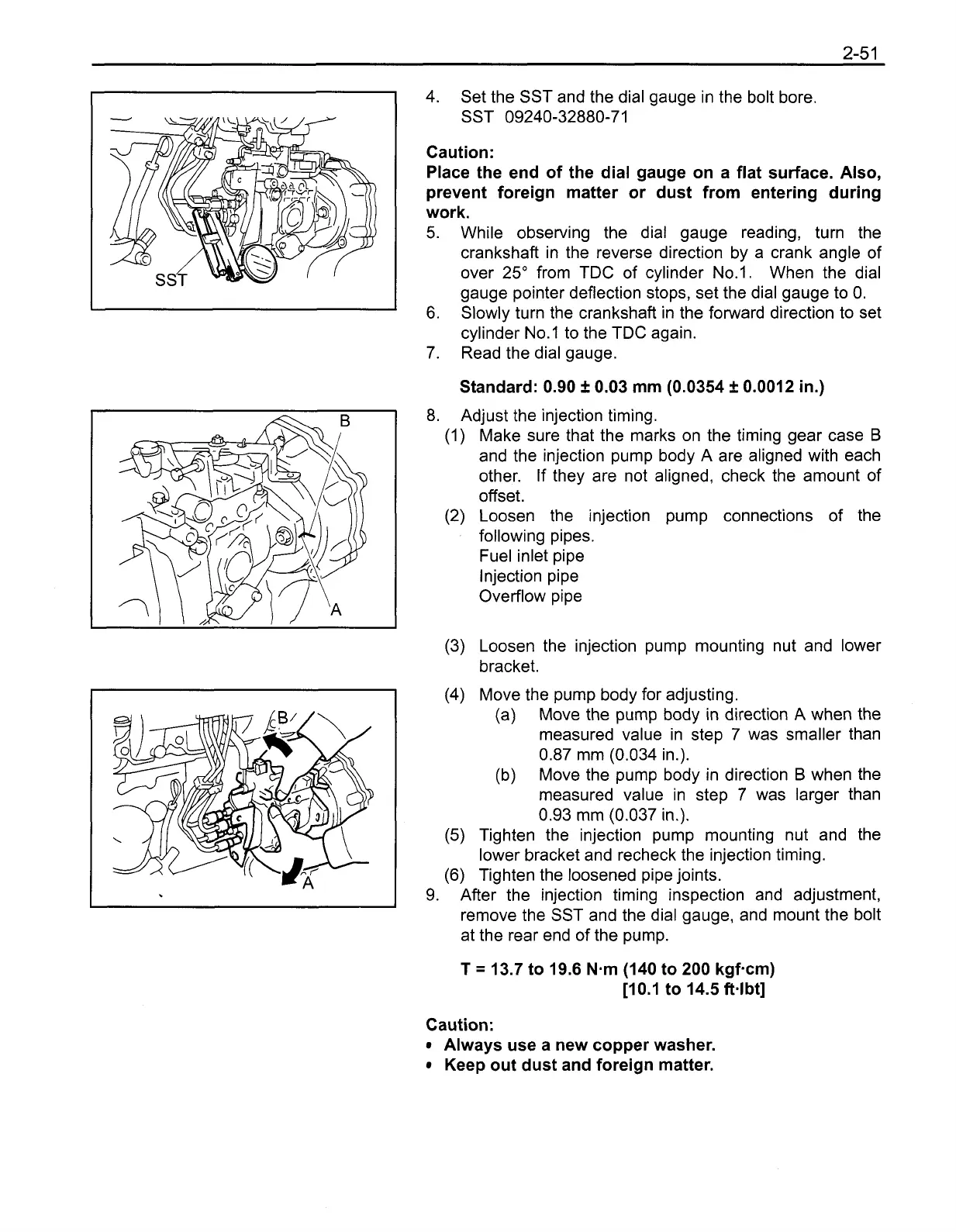

Set the SST and the dial gauge in the bolt bore.

SST 09240-32880-71

Caution:

Place the end of the dial gauge on a flat surface. Also,

prevent foreign matter or dust from entering during

work.

5.

While observing the dial gauge reading, turn the

crankshaft in the reverse direction by a crank angle of

over 25" from TDC of cylinder No.1. When the dial

gauge pointer deflection stops, set the dial gauge to 0.

6.

Slowly turn the crankshaft in the forward direction to set

cylinder No.1 to the TDC again.

7. Read the dial gauge.

Standard: 0.90

f

0.03 mm (0.0354

f

0.0012 in.)

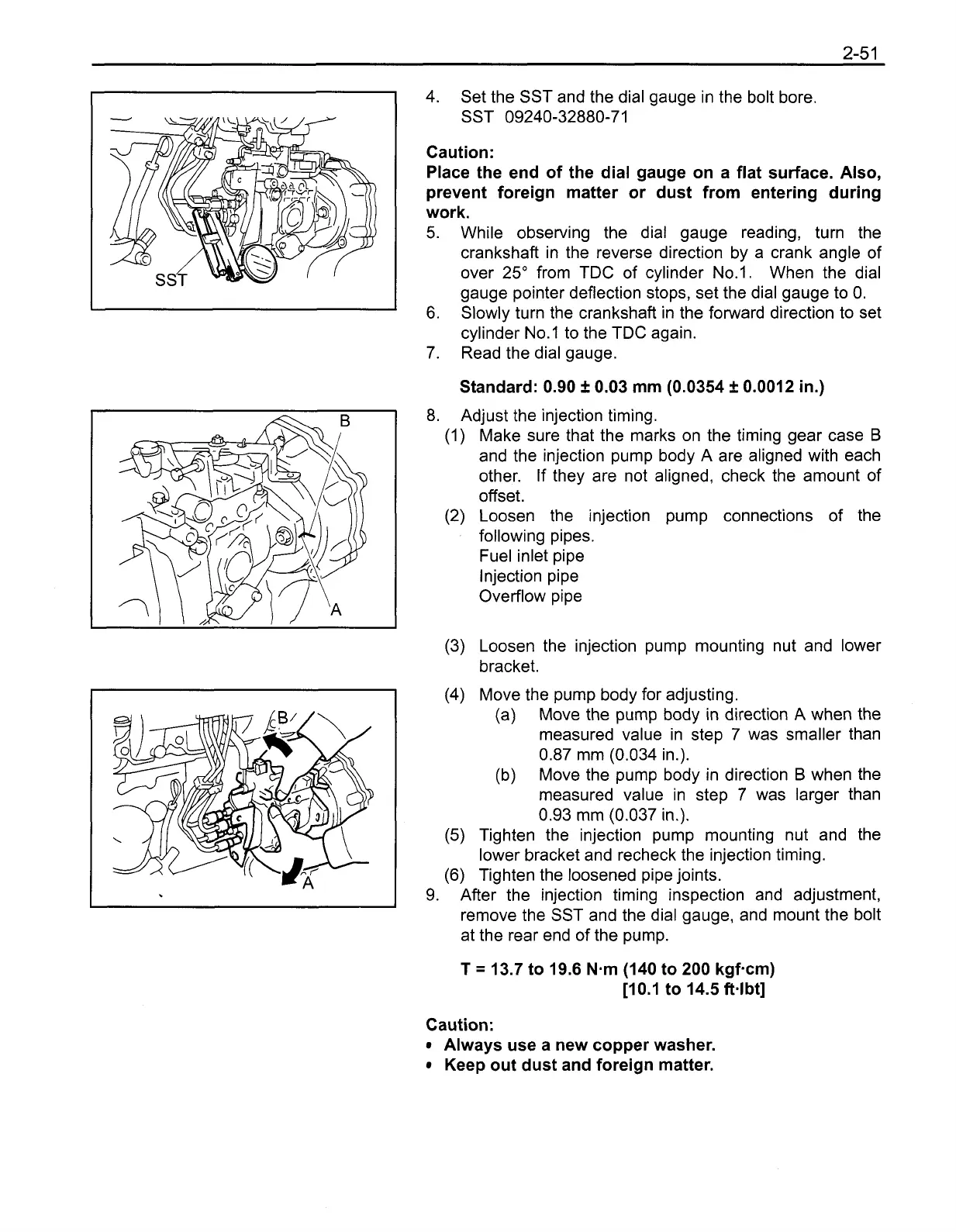

8. Adjust the injection timing.

Make sure that the marks on the timing gear case

B

and the injection pump body A are aligned with each

other. If they are not aligned, check the amount of

offset.

Loosen the injection pump connections of the

following pipes.

Fuel inlet pipe

Injection pipe

Overflow pipe

Loosen the injection pump mounting nut and lower

bracket.

Move the pump body for adjusting.

(a)

Move the pump body in direction A when the

measured value in step 7 was smaller than

0.87 mm (0.034 in.).

(b)

Move the pump body in direction

B

when the

measured value in step 7 was larger than

0.93 mm (0.037 in.).

Tighten the injection pump mounting nut and the

lower bracket and recheck the injection timing.

Tighten the loosened pipe joints.

9. After the injection timing inspection and adjustment,

remove the SST and the dial gauge, and mount the bolt

at the rear end of the pump.

Caution:

Always use a new copper washer.

Keep out dust and foreign matter.

Loading...

Loading...