CG-SVX027E-GB

19

11UNT-PRC002-GB

Sound power levels

Discharge

Measurement conditions:

Measurements taken in a room adjacent to the room containing the FWD, at the outlet of the rectangular duct (1.5 m

long) fixed to its discharge opening.

Fan Power level in dB(A), per Hz frequency band Overall power

Unit speed 125 250 500 1000 2000 4000 8000 dB(A)

1 55 50 42 37 37 31 30 46

FWD 08 2 57 54 47 40 30 38 40 50

3 58 57 50 42 32 40 43 53

1 57 51 45 42 34 33 28 48

FWD 10 2 58 54 48 45 38 39 35 51

3 60 58 50 48 40 42 39 54

1 57 51 45 42 34 33 28 48

FWD 12 2 58 54 48 45 38 39 35 51

3 60 58 50 48 40 42 39 54

1 56 62 50 48 39 38 36 56

FWD 14 2 61 66 55 53 47 46 45 60

3 63 69 58 56 50 50 49 63

1 57 63 51 49 40 39 37 57

FWD 20 2 61 66 55 53 47 46 45 60

3 63 69 58 56 50 50 49 63

Intake

Measurement conditions:

Measurements taken at the horizontal air intake.

Fan Power level in dB(A), per Hz frequency band Overall power

Unit speed 125 250 500 1000 2000 4000 8000 dB(A)

1 56 55 55 53 46 45 42 57

FWD 08 2 63 62 60 60 53 53 53 64

3 66 65 63 62 56 55 57 67

1 62 58 55 58 51 48 44 61

FWD 10 2 66 63 60 62 56 55 52 66

3 70 67 63 65 59 59 57 69

1 62 58 55 58 51 48 44 61

FWD 12 2 66 63 60 62 56 55 52 66

3 70 67 63 65 59 59 57 69

1 66 65 65 65 57 50 46 68

FWD 14 2 73 72 69 71 64 59 57 74

3 78 76 73 75 69 64 63 78

1 68 72 64 64 56 52 50 69

FWD 20 2 76 76 68 71 65 61 61 75

3 78 79 71 74 69 66 66 78

Installation – Mechanical

Location Requirements

Sound Considerations

The most effective form of acoustical isolation is to

locate the unit away from any sound sensitive area.

Structurally transmitted sound can be reduced by

elastomeric vibration eliminators. Spring isolators are

not recommended. Consult an acoustical engineer in

critical sound applications.

Foundation

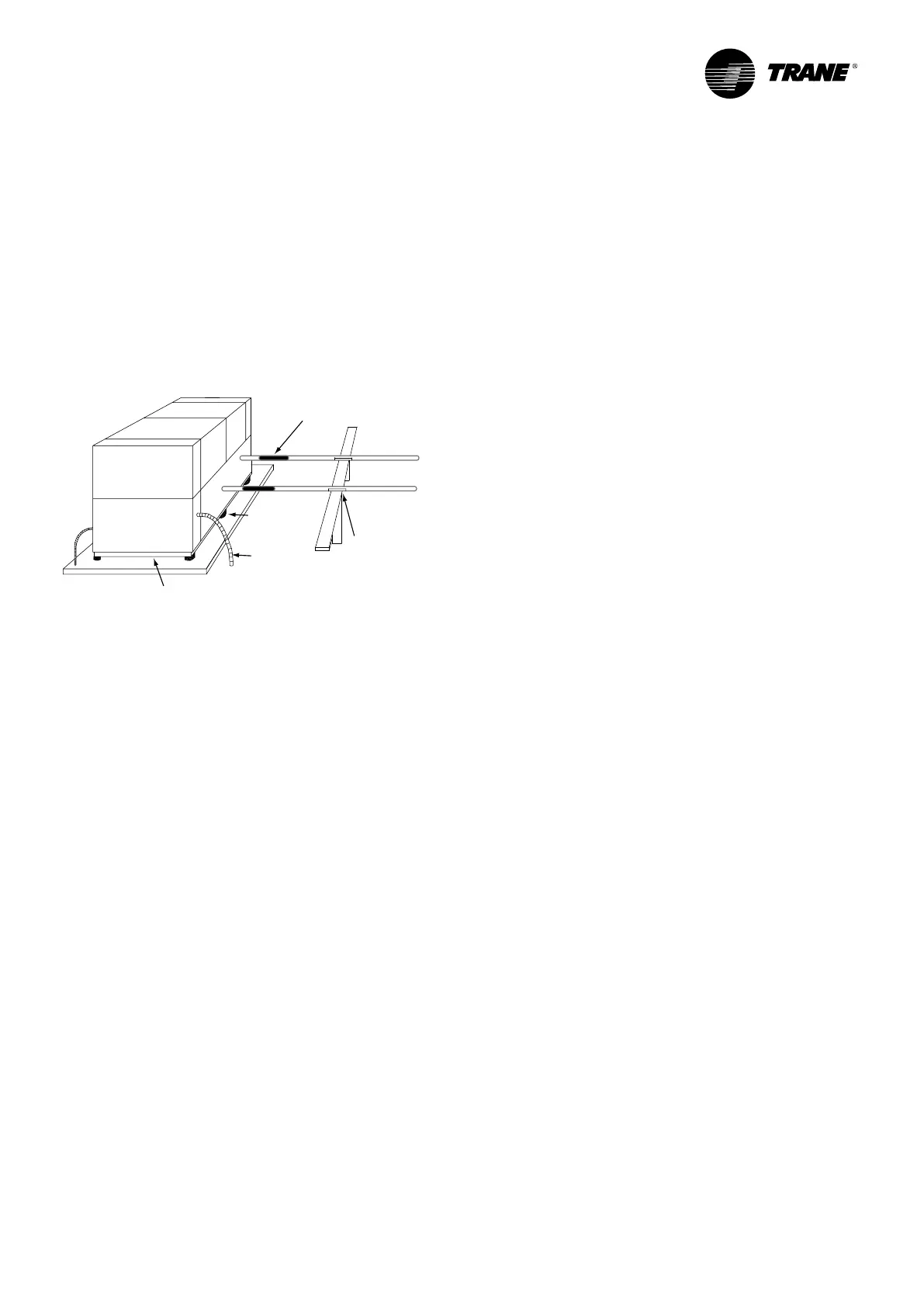

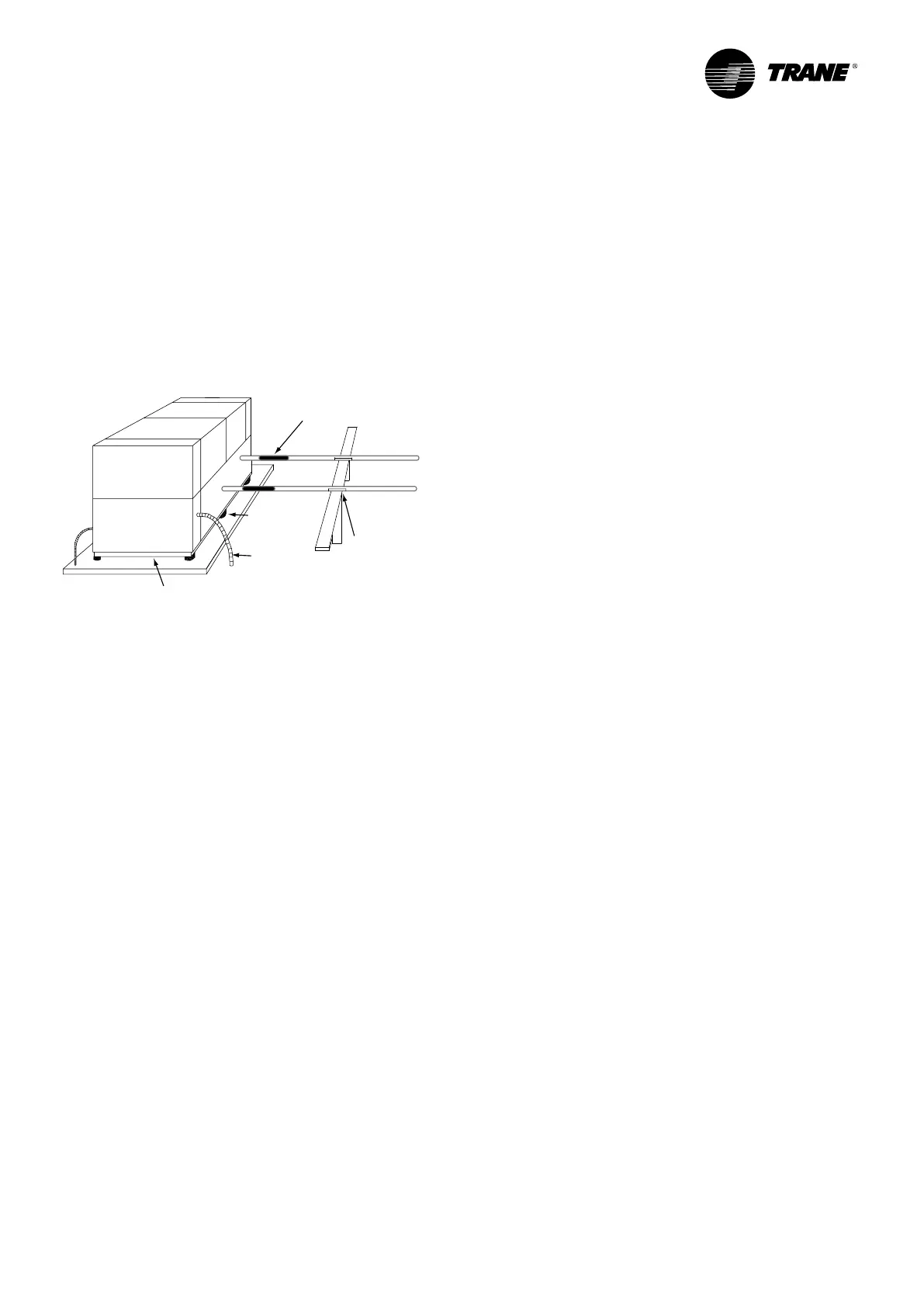

Figure 2 - Installation example

For maximum isolation effect, water lines and electrical

conduit should also be isolated. Wall sleeves and rubber

isolated piping hangers can be used to reduce the sound

transmitted through water piping. To reduce the sound

transmitted through electrical conduit, use exible

electrical conduit.

EU and Local codes on sound emissions should always

be considered. Since the environment in which a sound

source is located affects sound pressure, unit placement

must be carefully evaluated. Consult an acoustical

engineer for critical applications.

Provide rigid, non-warping mounting pads or a concrete

foundation of sufcient strength and mass to support

the applicable operating weight (i.e. including completed

piping, and full operating charges of refrigerant, oil and

water). Refer to the chapter on Unit Dimensions/Weights

for unit operating weights. Once in place, the unit must

be level with 3 mm over its length and width. Trane is

not responsible for equipment problems resulting from

an improperly designed or constructed foundation.

Clearances

Provide enough space around the unit to allow the

installation and maintenance personnel unrestricted

access to all service points. Refer to submittal drawings

for the unit dimensions, to provide sufcient clearance

for the opening of control panel doors and unit service.

Refer to the chapter on Unit Dimensions/Weights for

minimum clearances. In all cases, local codes which

require additional clearances will take precedence over

these recommendations.

If the installation includes several units or if units are

close to walls, contact your local Trane Sales Office for

additional requirements.

Winter operation: CXAX coil will not be obstructed at

any time by snow or ice.

Specic attention should be paid to avoid accumulation

of ice and snow at the bottom of the coil.

Rigging

Refer to weights tables for typical unit lifting weights.

Refer to the rigging label attached to the unit for further

details.

Lifting Procedure

Refer to the lifting label afxed to the unit. Lifting beam

crossbars MUST be positioned so lifting cables do not

contact the sides of the unit. Adjust as necessary for

even level lift.

1- Use the four rigging points which are built into the

unit.

2- Slings and a spreader bar are to be provided by the

rigger.

3 - The minimum lifting capacity of each sling as well

as the spreader bar must be equal or higher than the

tabulated unit shipping weight.

4- Caution: this unit must be lifted and handled with

care. Avoid shocks while handling.

Unit isolation and Leveling

Mounting

Construct an isolated concrete pad for the unit or

provide concrete footings at each of the four unit

mounting points. Mount the unit directly to the concrete

pads or footings. Level the unit using the base rail as a

reference. The unit must be level within 5 mm over the

entire length. Use shims as necessary to level the unit.

Isolation Pads installation (Optional)

Install the optional neoprene pads at each mounting

location. Refer to unit submittals for further details

on location. Consult a vibration engineer for critical

applications.

Evaporator piping

Evaporator water connections are grooved. Thoroughly

ush all water piping to the CGAX or CXAX units

before making the nal piping connections to the unit.

Components and layout will vary slightly, depending on

the location of connections and the water source.

CAUTION Equipment Damage!

If using an acidic commercial ushing solution, construct

a temporary bypass around the unit to prevent damage

to internal components of the evaporator.

CAUTION Proper Water Treatment!

The use of untreated or improperly treated water in a

chiller may result in scaling, erosion, corrosion, algae or

slime. It is recommended that the services of a qualied

water treatment specialist be engaged to determine

what water treatment, if any, is required. Trane assumes

no responsibility for equipment failures which result

from untreated or improperly treated water, or saline or

brackish water.

Loading...

Loading...