CG-SVX027E-GB

7

11UNT-PRC002-GB

Sound power levels

Discharge

Measurement conditions:

Measurements taken in a room adjacent to the room containing the FWD, at the outlet of the rectangular duct (1.5 m

long) fixed to its discharge opening.

Fan Power level in dB(A), per Hz frequency band Overall power

Unit speed 125 250 500 1000 2000 4000 8000 dB(A)

1 55 50 42 37 37 31 30 46

FWD 08 2 57 54 47 40 30 38 40 50

3 58 57 50 42 32 40 43 53

1 57 51 45 42 34 33 28 48

FWD 10 2 58 54 48 45 38 39 35 51

3 60 58 50 48 40 42 39 54

1 57 51 45 42 34 33 28 48

FWD 12 2 58 54 48 45 38 39 35 51

3 60 58 50 48 40 42 39 54

1 56 62 50 48 39 38 36 56

FWD 14 2 61 66 55 53 47 46 45 60

3 63 69 58 56 50 50 49 63

1 57 63 51 49 40 39 37 57

FWD 20 2 61 66 55 53 47 46 45 60

3 63 69 58 56 50 50 49 63

Intake

Measurement conditions:

Measurements taken at the horizontal air intake.

Fan Power level in dB(A), per Hz frequency band Overall power

Unit speed 125 250 500 1000 2000 4000 8000 dB(A)

1 56 55 55 53 46 45 42 57

FWD 08 2 63 62 60 60 53 53 53 64

3 66 65 63 62 56 55 57 67

1 62 58 55 58 51 48 44 61

FWD 10 2 66 63 60 62 56 55 52 66

3 70 67 63 65 59 59 57 69

1 62 58 55 58 51 48 44 61

FWD 12 2 66 63 60 62 56 55 52 66

3 70 67 63 65 59 59 57 69

1 66 65 65 65 57 50 46 68

FWD 14 2 73 72 69 71 64 59 57 74

3 78 76 73 75 69 64 63 78

1 68 72 64 64 56 52 50 69

FWD 20 2 76 76 68 71 65 61 61 75

3 78 79 71 74 69 66 66 78

Unit Description

Conquest chillers, CGAX, air cooled scroll compressor

type liquid chillers and CXAX heat pumps, are

designed for outdoor installation. Units can have one

or two independent refrigerant circuits, two or more

compressors per circuit. Unit are packaged with an

evaporator made with a braze plate heat exchanger, and

one or more condenser coils.

Each unit is completely assembled, hermetic package,

refrigerant circuit factory piped, electrical components

wired, leak tested, dehydrated, charged and tested

for proper control operations prior to shipment. The

chilled water inlet and outlet openings are covered for

shipment.

Units feature is Trane’s exclusive Tracer™ Symbio800

Control logic and controls. It monitors the control

variables that govern the operation of the unit.

A new generation of chiller control systems, providing

improved control capabilities. Integrated safety protocols

to protect both compressor and motor from electrical

faults like thermal overload and phase reversal.

Each refrigerant circuit is provided with lter, electronic

expansion valve, and charging valves.

In cooling mode on the CXAX or on the CGAX, the

evaporator is a brazed plate and frame heat exchanger

equipped with water drain and vent connections on the

water piping.

The condenser coil is available in four different

congurations: n and tube with aluminium ns, or

black epoxy pre-coating aluminum ns for the heat

pump versions, and MicroChannel type or E-coating

Microchannel type for the cooling only versions.

Accessory/options information

Check all the accessories and loose parts which are

shipped with the unit against the original order. Included

in these items will be rigging diagrams, wiring diagrams,

and service literature, which are placed inside the control

panel and/or starter panel for shipment. Also check for

optional components, such as couplings and pipe stubs

or neoprene pads.

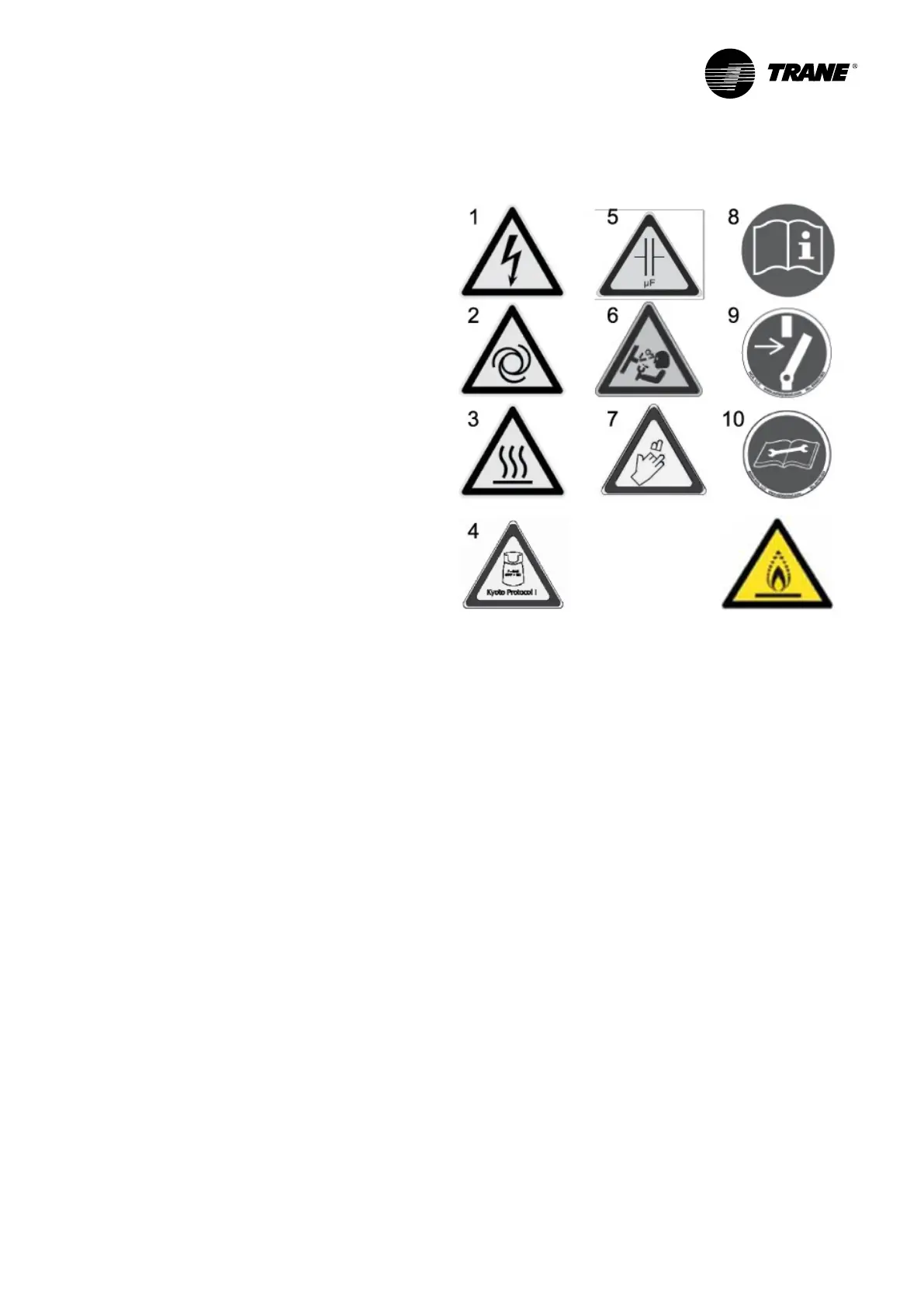

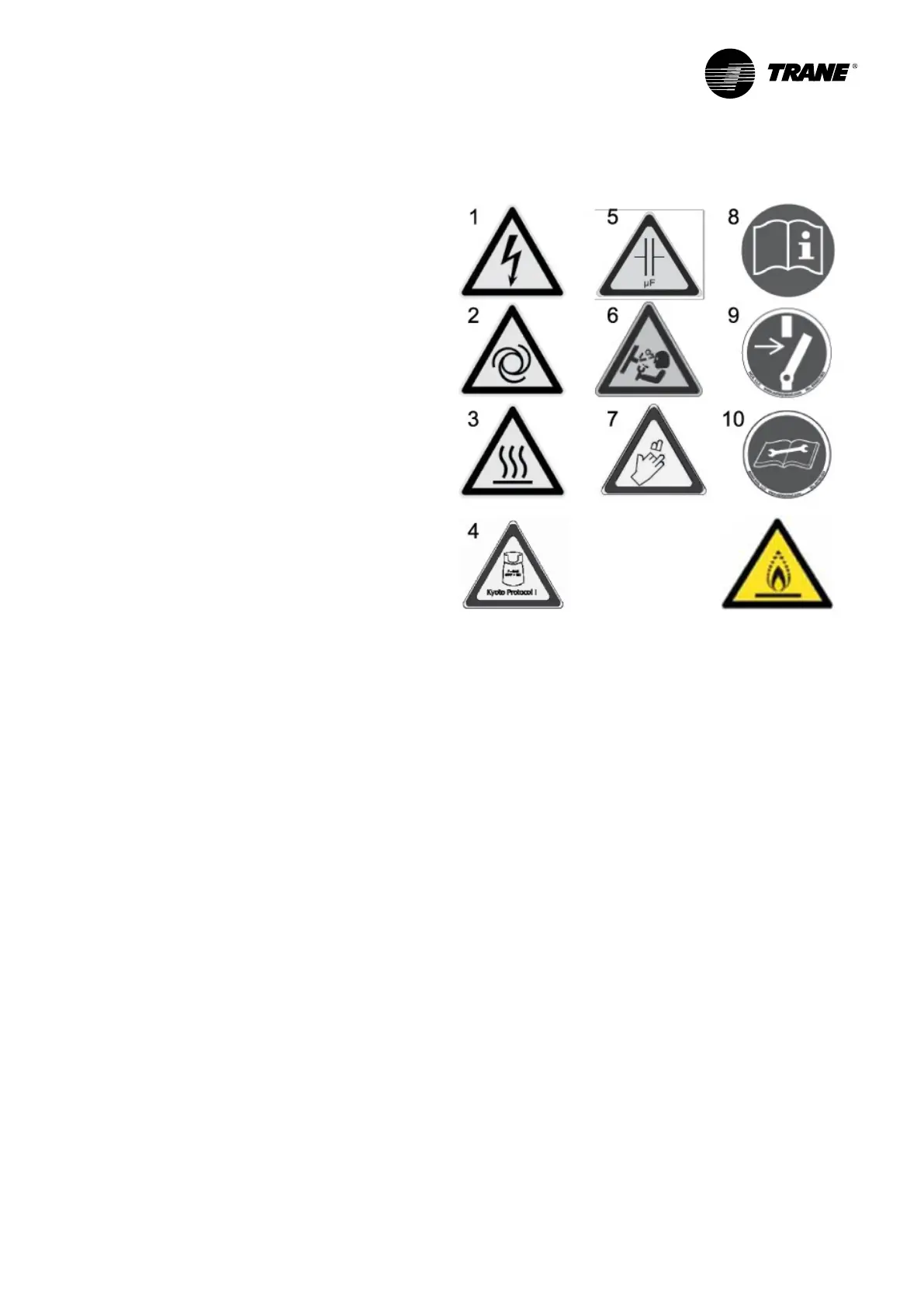

The following pictograms can be found on the unit. Take

necessary precautions to avoid damage and injury.

Figure 1 - Warning pictograms

11

1 = Risk that unit is powered up

2 = Risk hazard due to fan rotation

3 = Risk hazard of burns on compressors or refrigeration

piping

4 = Unit contains refrigerant gas. See specic warnings.

5 = Risk of residual voltage when speed drive or

softstarter or Low Ambient options are present

6 = Unit under pressure

7 = Risk to cut, particularly on heat exchanger ns

8 = Read instructions before installation

9 = Disconnect all electric power before servicing

10 = Read technical instructions

11 = Valuable for unit contains a mildly ammable

refrigerant R454B. Flammability risk hazard.

Loading...

Loading...