Routine Maintenance

CLCH-SVX07K-EN 161

6. Allow the unit to dry completely before putting it back

into service.

7. Be careful any contaminated material does not contact

other areas of the unit or building. Properly dispose of

all contaminated materials and cleaning solution.

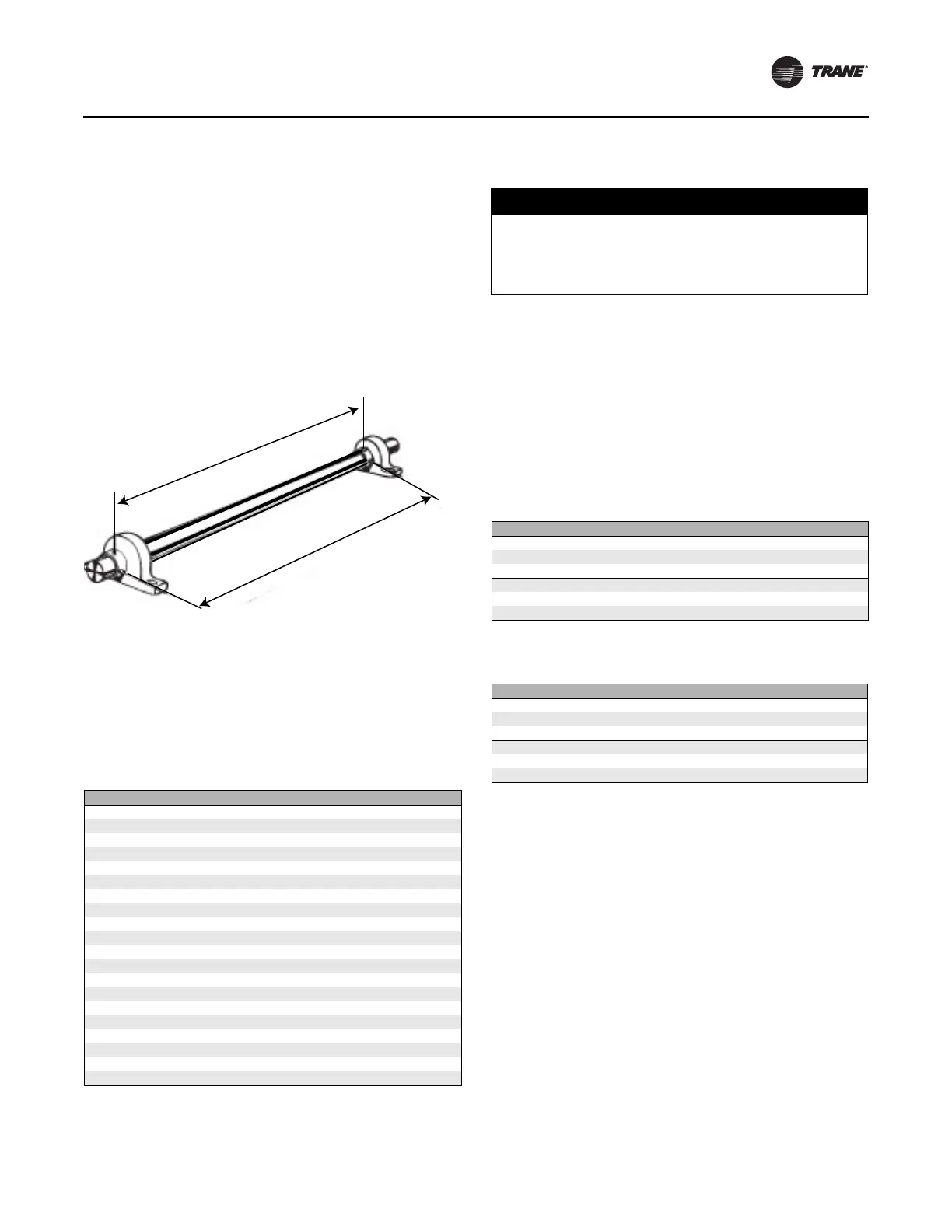

Bearing Set Screw Alignment

Align bearing set screws for belt-drive fans as illustrated in

Figure 205. See Table 41, p. 132 for set screw torque

measurements.

Torque Requirements

Refer to Table 53 for minimum torque of motor mounting

and bearings bolts. Refer to Table 41, p. 132 for minimum

setscrew torque.

Fan Bearing Lubrication

For belt-drive fans, the grease used in electric motor

bearings is usually not compatible with the grease used in

fan bearings. Never mix the two grease types! See

Table 54 for compatible greases and Table 55 for

maximum grease capacity.

Note: Lubricate the motor bearing according to the motor

manufacturer’s recommendations and use the

manufacturer-recommended grease. See “Motor

Bearing Lubrication,” p. 161.

• Fan bearings without lubrication lines are sealed

bearings. Re-lubrication is not required.

• Fan bearings equipped with lubrication lines should be

lubricated with a lithium-based grease that conforms

to NLGI No. 2 for consistency.

Motor Bearing Lubrication

Obtain an operation and maintenance manual from the

motor manufacturer for the specific motor installed. The

motor manufacturer’s recommendations take precedence

for all matters related to the start-up and routine

maintenance of the motor.

Motor grease fittings have been removed from factory-

installed motors in compliance with UL regulations. Motor

bearings require periodic maintenance throughout their

life. Many different styles of motors come as standard

selections, so please obtain the motor IOM and use the

manufacturer-recommended grease.

Figure 205. Alignment

Table 53. Minimum hex head bolt torque in lb.-ft.

(Grade 5 bolts)

Size (inches) Thread Designation Minimum Torque

1/4-20 UNC 6

1/4-28 UNF 7

65/16-18 UNC 14

5/16-24 UNF 16

3/8-16 UNC 24

3/8-24 UNF 28

7/16-14 UNC 42

7/16-20 UNF 45

1/2-13 UNC 69

1/2-20 UNF 83

9/16-12 UNC 99

9/16-18 UNF 118

5/8-11 UNC 150

5/8-18 UNF 176

3/4-10 UNC 254

3/4-16 UNF 301

7/8-9 UNC 358

7/8-14 UNF 422

1-8 UNC 500

1-14 UNF 602

Note: Soft metric conversions are not acceptable for screw and hex sizes.

Align set screws

Align set screws

NOTICE

Bearing Failure!

Mixing grease within the bearing could result in

premature bearing failure. Do not mix greases with

different bases within the bearing.

Table 54. Compatible Greases

Type

Texaco Multi Fak 2

Shell Alvania 2

Mobil 532

Chevron Dura-Lith 2

Exxon Beacon

Keystone 84H

Table 55. Fan bearing maximum grease capacity

Shaft size (inches) Capacity (fluid ounce)

1/2 - 3/4 1/7

7/8 - 1 3/16 3/8

1 1/4 - 1 1/2 5/8

1 11/16 - 1 15/16 7/8

2 - 2 7/16 1 1/4

2 1/2 - 2 15/16 2

Loading...

Loading...