Unit Start Up

128 RT-SVX36K-EN

3. Close the disconnect switch or circuit protector switch

that provides the supply power to the unit's terminal

block 1TB1 or the unit mounted disconnect switch 1S14

to allow the crankcase heater to operate a minimum of

8 hours before continuing.

Note: Compressor Damage could occur if the crankcase

heater is not allowed to operate the minimum of 8

hours before starting the compressor(s).

4. Turn the 115 volt control circuit switch 1S1 and the 24

volt control circuit switch 1S70 to the “On” position.

5. Open the Human Interface access door, located in the

unit control panel, and press the SERVICE MODE key to

display the first service screen. Refer to the latest

edition of the RT-SVP01*-EN for CV applications or RT-

SVP02*-EN for VAV applications for the SERVICETEST

screens and programming instructions.

6. Use Table 42, p. 96 to program the following system

components for operation by scrolling through the

displays;

• 20to36Ton

– Compressor 1A (On)

– Compressor 1B (Off)

– Condenser Fans

• 40 through 75Ton (VSC units only)

– Compressor 1A (On)

– Compressor 2A (Off)

– Compressor 2B (Off)

– Condenser Fans

• 40 through 130Ton

– Compressor 1A (On)

– Compressor 1B (Off)

– Compressor 2A (Off)

– Compressor 2B (Off)

– Condenser Fans

7. Attach a set of service gauges onto the suction and

discharge gauge ports for each circuit. Refer to

Figure 84, p. 130 for the various compressor locations.

8. Once the configuration for the components is

complete, press the NEXT key until the LCD displays

the “Start test in __Sec.” screen. Press the + key to

designate the delay before the test is to start.This

service test will begin after theTEST START key is

pressed and the delay designated in this step has

elapsed. Press the ENTER key to confirm this choice.

9. Press theTEST START key to start the test. Remember

that the delay designated in step 8 must elapse before

the system will begin to operate.

10. It is very important to review and follow the Electrical

Phasing procedure described in the startup procedure

of the IOM. If the compressors are allowed to run

backward for even a very short period of time, internal

compressor damage may occur and compressor life

may be reduced. If a scroll compressor is rotating

backwards, it will not pump, make a loud rattling sound

and low side shell gets hot. Immediately shut off the

unit. If the phasing is incorrect, interchange any two

compressor leads to correct the motor phasing.

11. Press the STOP k ey at the Human Interface Module in

the unit control panel to stop the compressor

operation.

12. Repeat steps 5 through 11 for each compressor stage

and the appropriate condenser fans.

Refrigerant Charging

1. Attach a set of service gauges onto the suction and

discharge gauge ports for each circuit. Refer to

Figure 84, p. 130 for the various compressor locations.

2. Open the Human Interface access door, located in the

unit control panel, and press the SERVICE MODE key to

display the first service screen. Refer to the latest

edition of the programming manual for CV or VAV

NOTICE:

Compressors Damage!

Do not allow liquid refrigerant to enter the suction line.

Excessive liquid accumulation in the liquid lines could

result in compressor damage.

COMPRESSOR SERVICE VALVES MUST BE FULLY

OPENED BEFORE START-UP (SUCTION, DISCHARGE,

AND LIQUID LINE)

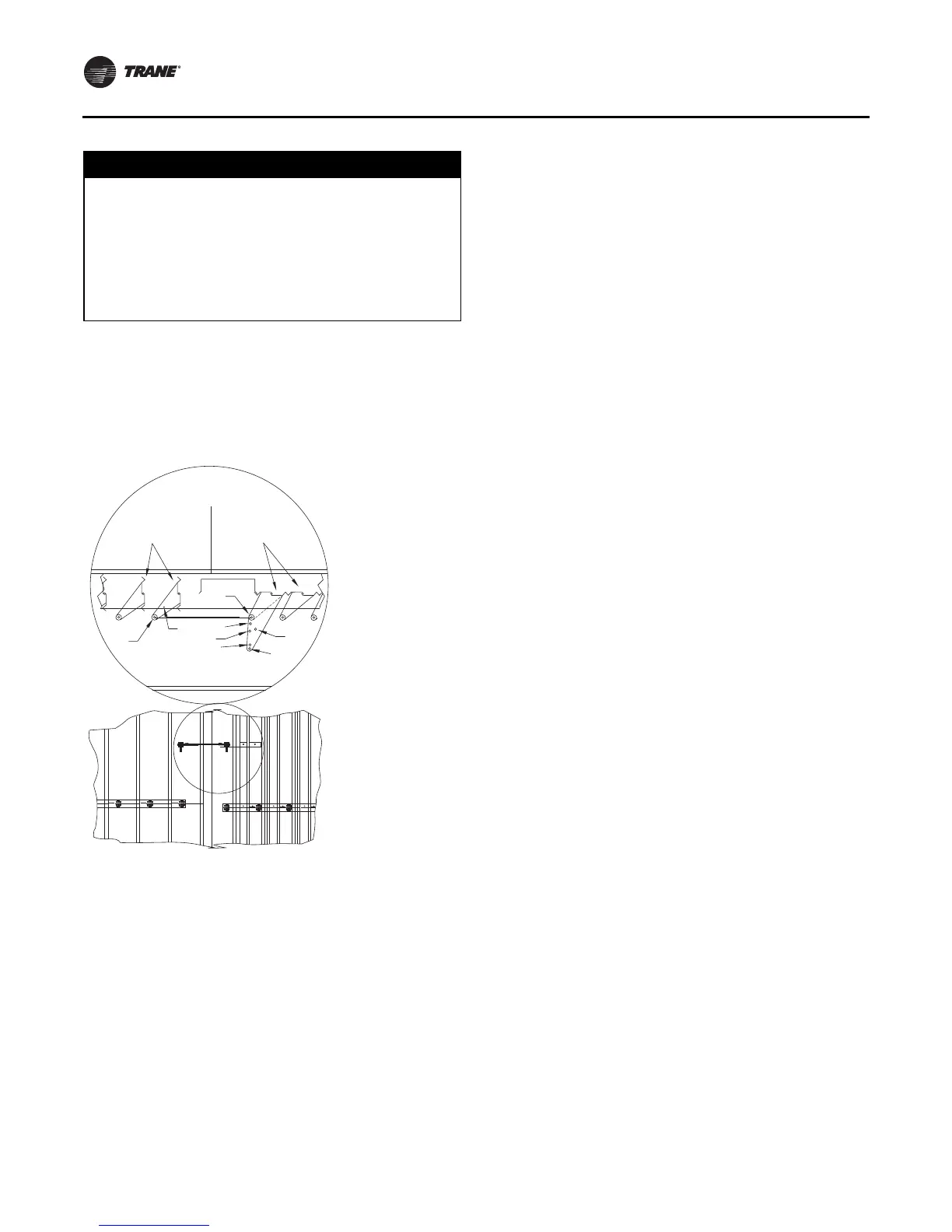

Figure 83. Outside air and return air linkage adjustment

RETURN AIR

DAMPERS

OUTSIDE AIR

DAMPERS

FILTER

SECTION

2

1

3

4

5

6

7

8

Top View

Loading...

Loading...