Installation

42 RT-SVX36K-EN

Units with Gas Furnace

Units equipped with a gas furnace have a 3/4” CPVC drain

connection stubbed out through the vertical support in the

gas heat section. It is extremely important that the

condensate be piped to a proper drain. Refer to the

appropriate illustration in Figure 14 and Figure 15 for the

location of the drain connection.

Note: Units equipped with an optional modulating gas

furnace will likely operate in a condensing mode

part of the time.

An additional 1-1/4” non-connectable water drain is

located in the base rail within the heating section.

Ensure that all condensate drain line installations comply

with applicable building and waste disposal codes.

Removing Supply and Exhaust/Return Fan

Shipping Channels (Motors >5Hp)

Each FC supply fan assembly and exhaust fan assembly

for S_HL units shipped with a motor larger than 5 HP is

equipped with rubber isolators (as standard) or optional

spring isolators. Each DDP supply fan assembly for SAHF

and SXHL units is equipped with spring isolators. Each

return fan assembly for S_HL units shipped with a motor

larger than 5 HP is equipped with spring isolators.

Shipping channels are installed beneath each fan

assembly and must be removed.To locate and remove

these channels, refer to Figure 26 and Figure 28, and use

the following procedures:

Rubber Isolators:

1. Remove and discard the shipping bolts from the fan

assembly rails.

2. Elevate the fan-and-motor assembly and slide the

shipping channels out from between the fan assembly

rails and the unit's base rail.

3. Lower the fan-and-motor assembly onto the isolators.

Make sure that the pins at the top of the isolators are

engaged in the corresponding holes on the fan

assembly.

4. Verify that the fan assembly is being supported by the

isolators.

Spring Isolators: See Figure 26, Figure 28, Figure 27

and Figure 29 for spring isolator locations.

1. Remove and discard the shipping tie down bolts.

2. Remove the shipping channels and discard.

Note: Fan assemblies not equipped with rubber or spring

isolators have mounting bolts at the same

locations and must not be removed.

Note: If return fan backside spring isolator repair/

replacement is required, access the backside of the

return fan by entering the unit filter section.

Remove the top pivot bearings from the three

fixed- position return damper blades (bolted

together as a single section with an angle brace).

Lift the three-blade section as a single unit from the

return damper assembly and set aside or lean in

against the return fan frame.Then enter the return

fan compartment from the filter section to perform

service work on the rear isolators.

Optional DDP Supply Fan Shipping

Channel Removal and Isolator Spring

Adjustment

ShippingTie Down and Isolator Spring Adjustment-

Remove shipping tie down bolt and washer (4 - 20 to 30

ton,6-40to55ton,8-60to75ton). Leave shipping

channels in place. Verify spring height is 0.1" to 0.2"

above shipping channel. Spring height is factory set but

verify and adjust as needed by: 1) Back off ALL spring

isolator jam nuts (4) at top of assembly (adjusting one

spring effects all others) 2) Turn adjustment bolt (make

small adjustments, again each change effects all other

springs. Clockwise raises, Counter clockwise lowers).

When correctly adjusted re-tighten jam nuts and remove

shipping channels. Do Not Remove electrical

ground wire strap between isolation base and unit

base.

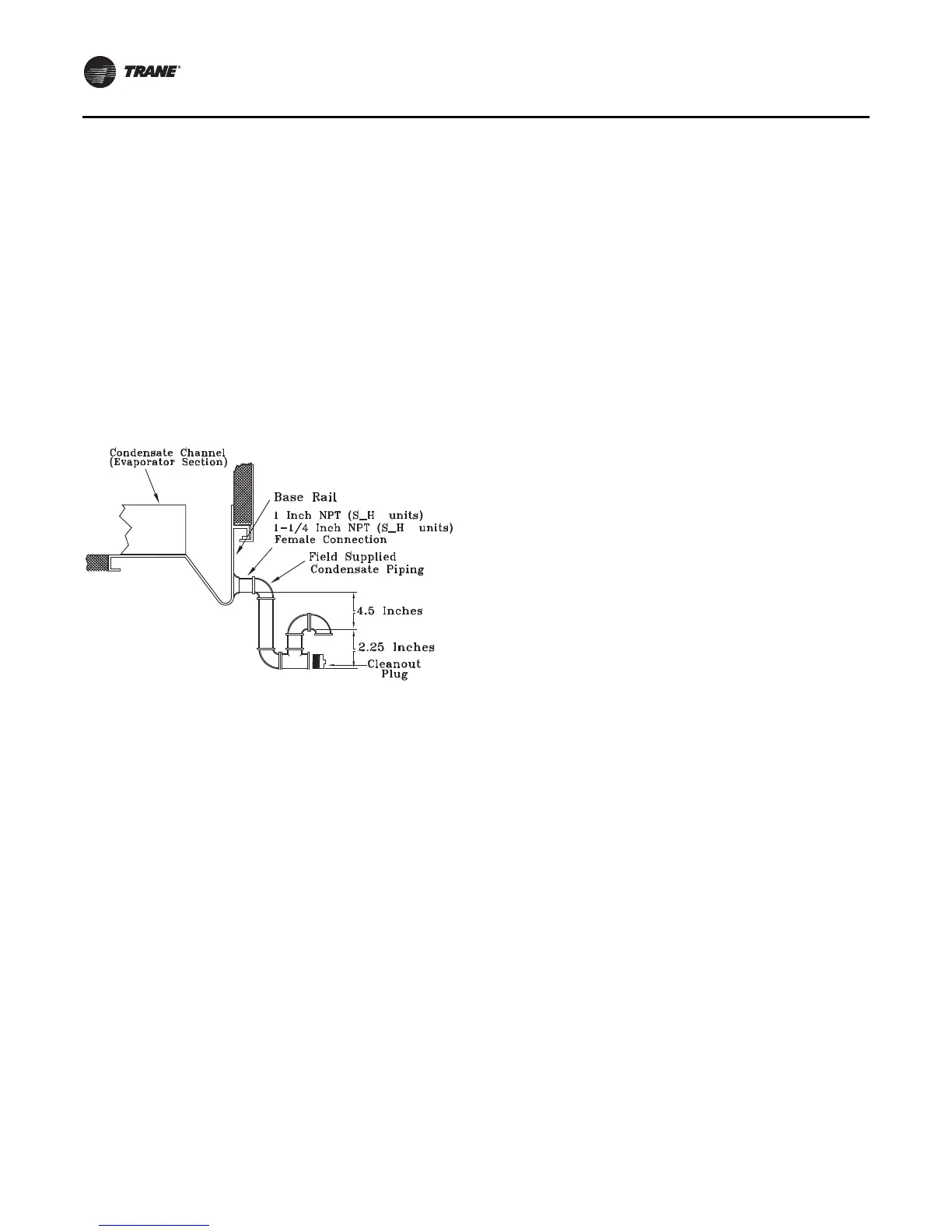

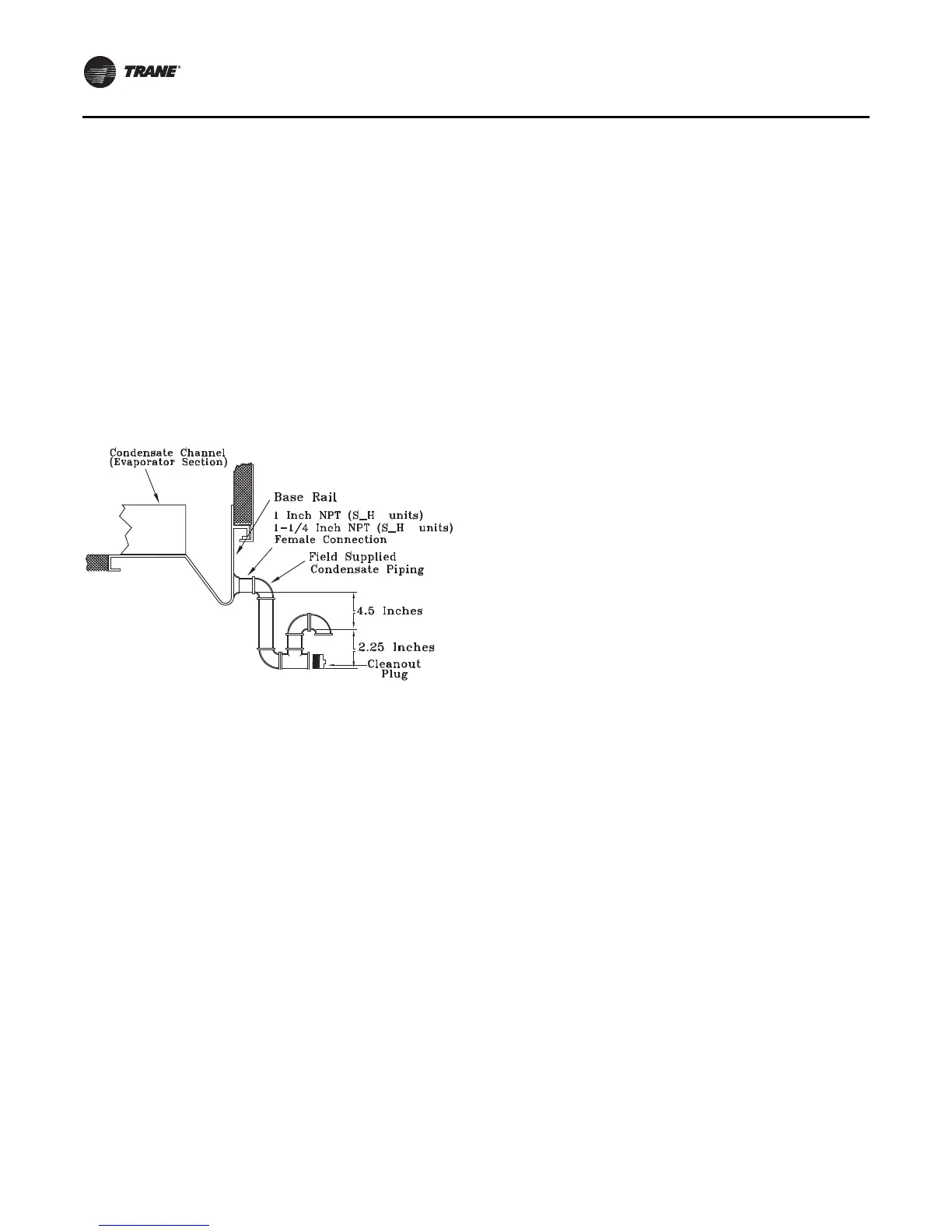

Figure 24. Condensate trap installation

L

G

Loading...

Loading...