Maintenance

182 RT-SVX36K-EN

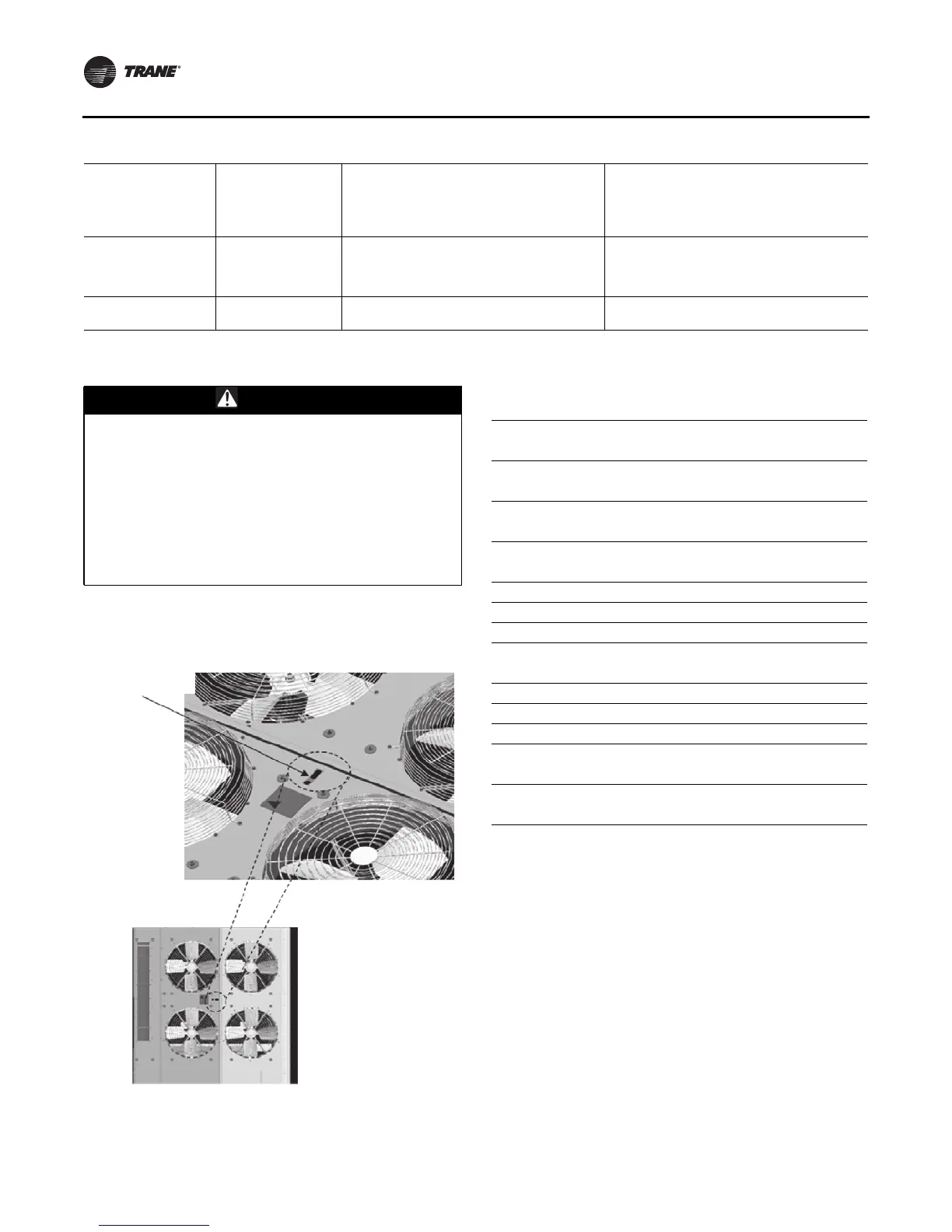

Fall Restraint

The fall restraint is located approximately 3 feet from the

unit edge. Figure 137, p. 182

Final Process

For future reference, you may find it helpful to record the

unit data in the blanks provided.

Sump Pump Does not run

Sump Pump Overload Trip Low Water Level or

faulty float switch. Unit in ‘Dry Mode’ Operation

Reset – check amps on each leg to determine if

faulty motor. Check and clean debris around float

switch. Check Ambient thermostat setting and

mode of operation (close on rise). See section 2

for T’stat setup instructions.

Sump Pump Low Flow

Pump may be operating backwards or impeller

inlet may be slightly blocked.

Change pumping direction by changing any two

legs to the pump motor. Disconnect Power and

remove pump to inspect for possible impeller

obstruction.

Spray Nozzle Dry area on coil

Check for proper spray pattern over each

quadrant.

Remove debris from clogged nozzle.

Table 79. Evaporative Condenser Models—Maintenance and Troubleshooting (continued)

WARNING

Falling Off Equipment!

This unit is built with fall restraint slots located on unit

top that MUST be used during servicing. These slots

are to be used with fall restraint equipment that will

not allow an individual to reach the unit edge. However

such equipment will NOT prevent falling to the ground,

for they are NOT designed to withstand the force of a

falling individual. Failure to use fall restraint slots and

equipment could result in individual falling off the unit

which could result in death or serious injury.

Figure 137. Fall restraint

Fall restraint

Complete Model Number:

Unit Serial Number:

Unit “DL” Number (“Design special” units only):

Wiring diagram numbers (from unit control panel):

-schematic(s)

-connections

Unit Address (TCI)

Network ID (LCI or BCI)

Loading...

Loading...