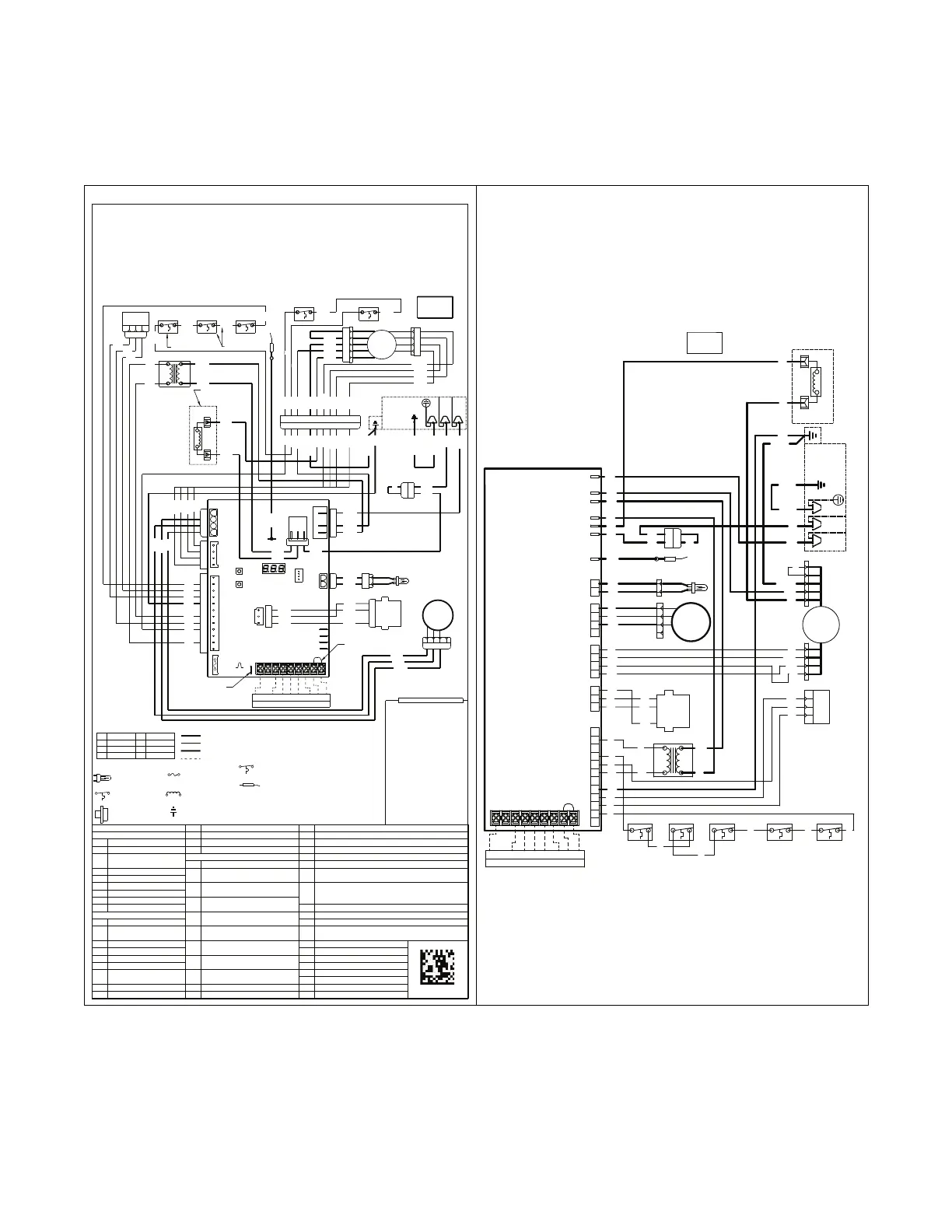

BK BLACK GR GREEN

WH WHITE BR BROWN

YL YELLOW RD RED

OR ORANGE BL BLUE

Variable Speed Inducer and Blower Motor

Hod

Heat Off Delay (sec)

E6.1

Voltage reversed polarity

Status Codes

15d

Inter-Stage Delay (sec)

E6.2

Bad Grounding

IdL

Idle

9HC

Gas Heating CFM (Airflow x10)

E6.3

(1) Igniter relay fails, (2) Igniter open

Ht1

Gas Heating

rUn

Run Test Mod

e

E7.1

1st s

tage gas valve (MVL) is energized when it should be off

ArF

Airflow (followed by

Airflow x 10)

Error

Codes

E7.2

Redun

dant Relay (HLO output) energized when it should be off

E01

Loss of the IRQ/other internal failures

E08

Flame current is low, but still strong enough to allow operation.

COF

Continuous Fan

E2.1

Retry exceeded (Failed to est flame)

One hour lockout time

E10

Inducer motor no communication response. Possibly caused by a

communication failure between two microcontrollers.

CL1

1st Stage Cooling

CL2

2nd Stage Cooling

E2.2

Recycles exceeded (loss of established

flame). One hour lockout time

E11

(1) 1st stage gas valve energized when it should not be

(2) 1st stage gas valve not energized when it should be

(3) Redundant relay (HLO output) not energized when it should be

HP1

1st Stage Heat Pump

HP2

2nd Stage Heat Pump

E2.3

1st Stage Gas Valve not energized when

it should be. One hour lockout time

dFt

Defrost Mode

E12

Open fuse

Menu Options

E2.4

HLO relay not energized when it should be

One hour lockout time

E13

Blower HP/OEM ID

Err

Active Alarm Menu

E14

No PM and local copy bad

L6.F

Last 6 Faults (To Clear,

Hold Option Button 5 sec)

E3.1

Signal Not Present <0.25V @ 5.0V

supply BK(VCC)-RD(GND)

E15

Both Unit Data File in PM and local Unit

Data File are Corrupt

Cr

Code Release Number

E3.2

Signal Out of Bounds >4.25V @ 5.0V

supply BK(VCC)-RD(GND)

E17

Blower motor no communication response

D346645P01 REV D

COd

Cooling Off Delay (sec)

E18

Blower communication failure on the control

ODT

Outdoor Tonnage

E3.3

Insufficient Pressure Pressure Less than

Target >10 seconds BK(VCC)-RD(GND)

0dU

Outdoor Unit

C0F

Blower Constant Fan Airflow

Multiplier %

E04

Open Thermal Limit, Burner Box Limit,

or Reverse Airflow Switch

CPC

Cooling (CFM/Ton)

E05

Flame detected, should not be present

CPH

Heat Pump Heating (CFM/Ton)

WH/16

WH/16

WH/20

BK/21

BL/2

BL/2

BL/4

BL/4

RD/5

RD/5

GR/6

WH/11

GR/YL/29

GR/YL/29

BK/28

BK/28

L8V1

ELECTRICAL RATING

INPUT: 24 VAC, 60 HZ

XFMR SEC. CURRENT: 450 MA. + MV LOAD

MV OUTPUT: 1.5A @ 24 VAC

IND OUTPUT: 2.2 FLA, 3.5 LRA @120 VAC

IGN OUTPUT: 2.0 A @ 120 VAC

CIRC. BLOWER OUTPUT:

14.5 FLA, 25 LRA @ 120 VAC

HUMIDIFIER & AIR CLEANER 120VAC

OUTPUT MAX. LOAD: 1.0 A @ 120 VAC

FUSE

: 5A

TIMINGS

PREPURGE: 30 SEC.

INTERPURGE: 60 SEC.

POST PURGE: 5 SEC.

IGN WARMUP: 20 SEC.

IAP:

2 SEC.; TFI: 5 SEC.

RETRIES: 6 RECYCLES: 10

HEAT ON DELAY: 30 SEC.

COOL ON DELAY: 0 SEC.

AUTO

RESTART: 60 MIN.

INTEGRATED FURNACE CONTROL

LINE

24 V

LINE

24 V

FIELD

WIRING

}

}

FACTORY

WIRING

RAF REVERSE

AIR FLOW

PT PRESSURE

TRANSDUCER

FP FLAME PROBE

IGN HOT SURFACE

IGNITER

** INTERNAL THERMAL

PROTECTION

FUSE

GROUND

PANEL LOOP

FP FLAME PROBE

GND GROUND

H LINE

HLI HIGH LIMIT INPUT

HLO HIGH LIMIT OUTPUT

IFC INTEGRATED FURNACE CONTROL

IGN IGNITER

IND INDUCER

MV MAIN VALVE

MVC MAIN VALVE COMMON

MVH MAIN VALE HIGH

MVL MAIN VALVE LOW

N NEUTRAL

RAF REVERSE AIRFLOW

Rx RECEIVE SIGNAL

TH 24VAC (HOT)

TNS TRANSFORMER

TR 24VAC (COMMON)

Tx TRANSMIT SIGNAL

VCC COMMON COLLECTOR VOLTAGE

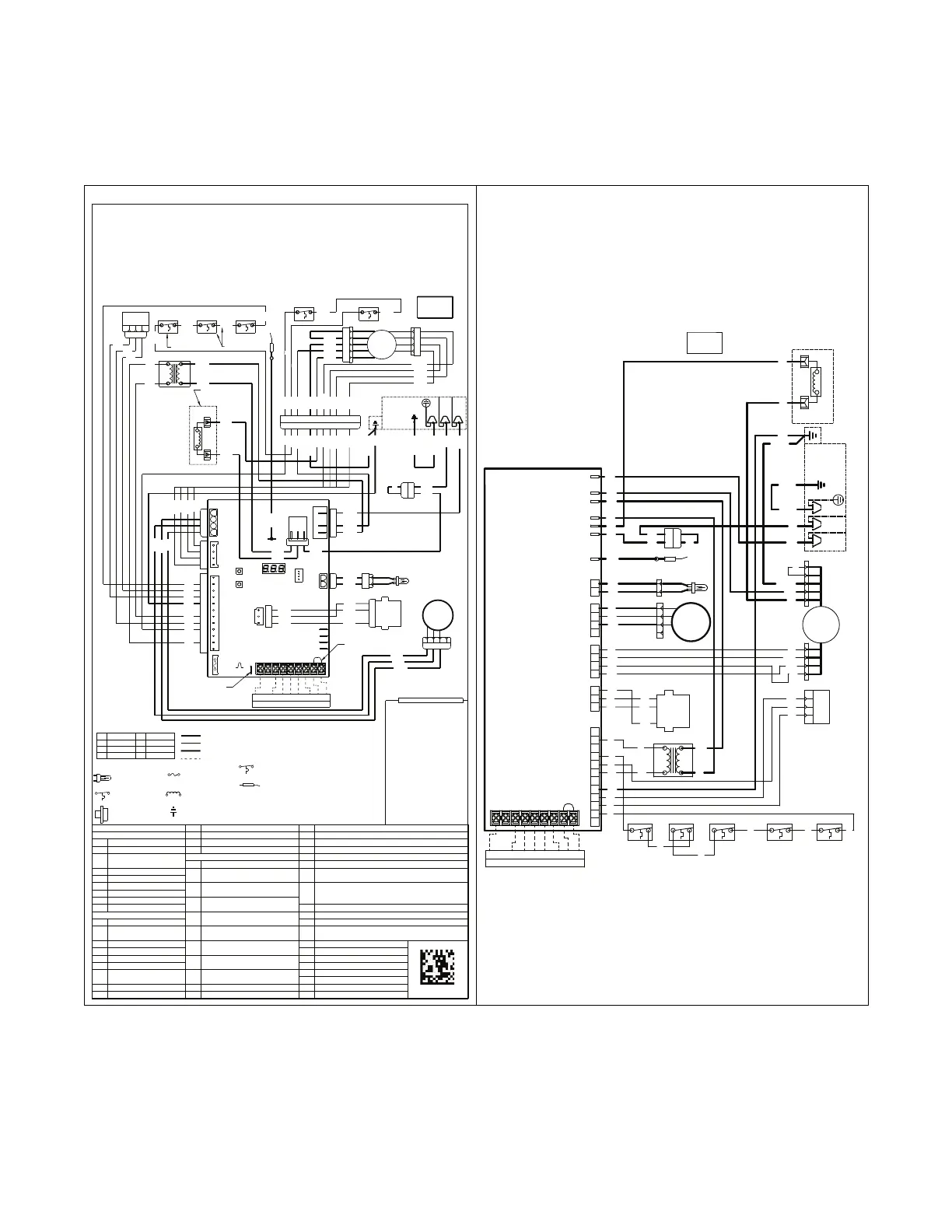

WH/14

WH/14

WH/15

WH/15

YL/10

YL/10

BK/13

BK/13

BK/12

BK/12

BK/35

53/KB

BK/27

LC LINE CHOKE

YL/31

GR/BK/30

RD/34

BK/32

BK/27

RD/34

GR/BK/30

GR/6

YL/9

YL/9

SEE NOTE 9

BK

THERMAL LIMIT

YL/44

YL/42

YL/43

GR/41

GR/41

WH/40

WH/40

BK/39

BK/39

BK/38

BK/38

WH/37

WH/37

WH/36

WH/36

BL/35

BL/35

YL/45 YL/45

YL/3

YL/3

RD/7

RD/7

BR/8

BR/8

BK/32

BK/17

BK/17

RD/18

RD/18

WH/19

WH/19

BK/23

32/KB

WH/24

42/HW

WH/25

52/HW

BL/26

BL/26

YL/22

NOTES:

1. IF ANY OF THE ORIGINAL WIRING AS SUPPLIED WITH THIS FURNACE MUST BE REPLACED, IT MUST BE WITH WIRE HAVING A TEMPERATURE RATING OF AT

LEAST 105ºC.

2. FOR PROPER AIRFLOW IN COOLING/HEAT PUMP MODES, Y1 AND/OR Y2 MUST CONNECT FROM THE THERMOSTAT TO THE IFC LOW VOLTAGE TERMINAL STRIP.

3. FOR COOLING ONLY SYSTEMS, LEAVE Y1-O JUMPER IN PLACE ON THE IFC FOR CORRECT LED READOUT.

4. FOR HEATPUMP SYSTEMS, REMOVE THE Y1-O JUMPER, CONNECT "O" FROM THE THERMOSTAT TO "O" ON THE IFC LOW VOLTAGE TERMINAL STRIP FOR

CORRECT LED READOUT.

5. VSPD OD SYSTEMS REQUIRE DIFFERENT CONNECTIONS, SEE RELAY PANEL INSTRUCTIONS.

6. THE "BK" JUMPER MUST BE CUT WHEN APPLYING AN AIRFLOW COMMAND TO THE "BK" TERMINAL SUCH AS PULSE WIDTH MODULATION OR WHEN

PAIRED WITH A VSPD OD UNIT.

7. AIRFLOW TABLES ARE LOCATED IN THE SERVICE FACTS. TO CHANGE AIRFLOW, REFER TO THE INTEGRATED FURNACE CONTROL MENU AND OPTIONS

TO SET AIRFLOW AND BLOWER DELAYS.

8. CORRECT PERSONALITY MODULE IS REQUIRED FOR PROPER FURNACE OPERATION AND IS SPECIFIC TO EACH MODEL & SERIAL NUMBER. IT IS TO

REMAIN WITH THE ORIGINAL UNIT.

9. LINE CHOKE AND WIRE BK/35 ONLY USED ON MODELS WITH 1 HP MOTORS.

10. THERMAL LIMIT SWITCH 1 IS FOR UPFLOW, RIGHT SIDE RETURN ONLY ON C100 MODEL.

11. THERMAL LIMIT SWITCH 2 AND WIRE 31 ONLY PRESENT IN C100 MODEL.

SEE NOTES 2, 3, 4, 5

SEE NOTE 6

GR/33 GR/33

JUMPER

SEE NOTE 4

SEE NOTE 10

X X

24v

120v

TNS

GAS

VALVE

1

2

3

IGN

X

FLAME PROBE

X

1 2 3 4 5 6 7 8 9 10 11 12

2

1

LINE CHOKE

1 2 3 4

THERMAL-LIMIT-1

1

2

3

4

X

JUNCTION BOX

120v 60 Hz. 1 PH

POWER SUPPLY PER LOCAL CODE

H N

GND

PRESSURE

TRANSDUCER

1

2

3

4

BBOX-LIMIT

1

2

1

2

1 2 3

BLOWER

MOTOR

AC

AC

GND

2JPR

1JPR

GND

Rx

Tx

12V

RAF-1

4

3

2

1

1

2

3

4

5

RAF-2

121110987654321

BK W1 R G B/C Y2 Y1 O

THERMOSTAT

LINE

NEUTRAL

5AMP

MENU

OPTION

EAC

HUM

GND 3

FP

IFC

BK JUMPER

E47

E21

E19

E23

E25

E26

E39

E32

1 IND-(W)

2 IND-(V)

3 IND-(U)

4 N/A

E12

1 12V

2 RX

3 GND

4 TX

E14

E5

N 1

H 2

E18

VCC 1

PI 2

12 N/A

11 HLI

9 MVL

8 GND

10 MVH

7 N/A

6 TH

5 MVC

4 HLO

1 N/A

2 TR

3 N/A

PERSONALITY

MODULE

BK

W1

R

G

B/C

Y2

Y1

O

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

4

3

2

1

2

1

1 2 3

4

3

2

1

1

2

3

THERMAL-LIMIT-2

VENT

MOTOR

(INDUCER)

**

SEE NOTE 11

Loading...

Loading...