68 RTAA-SVX01A-EN

Operating Principles

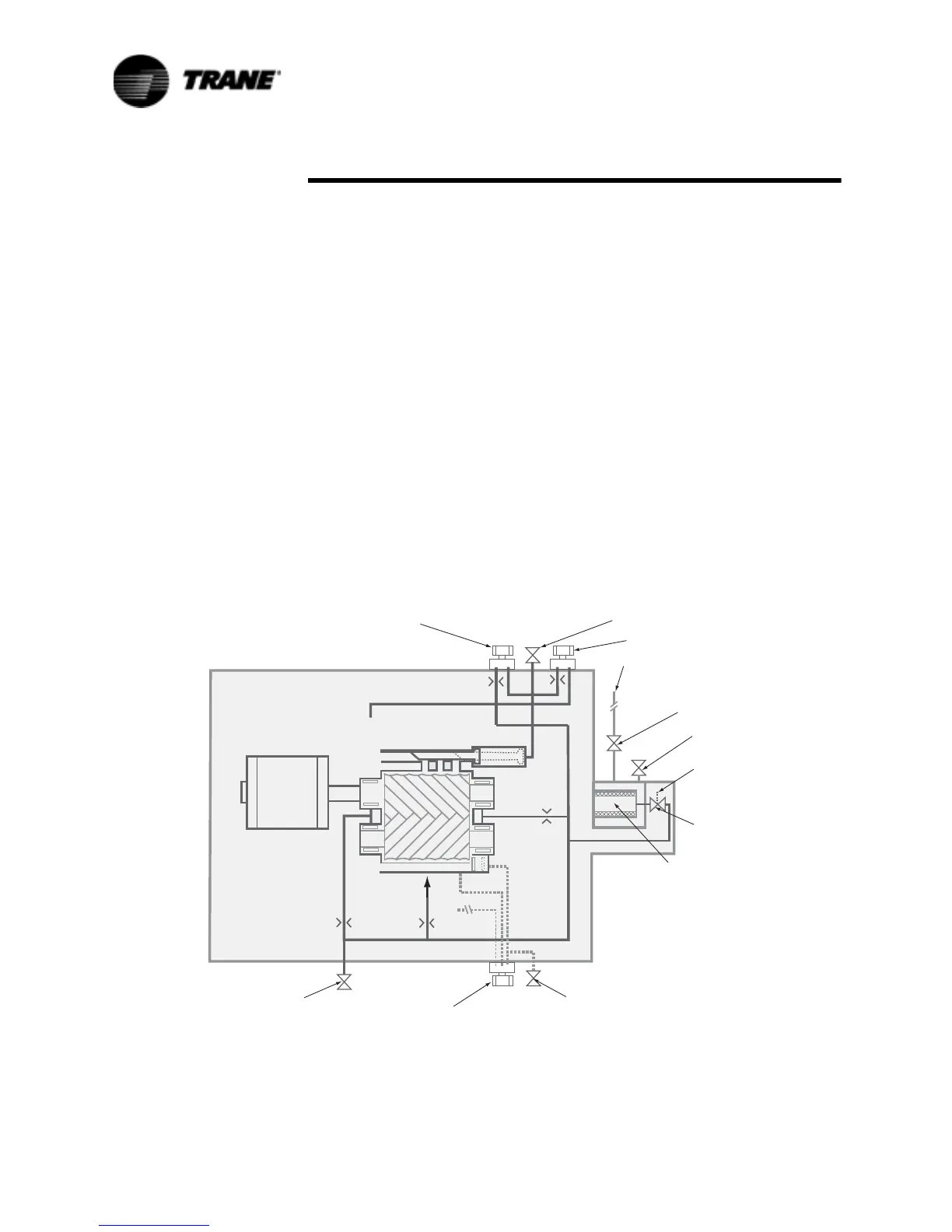

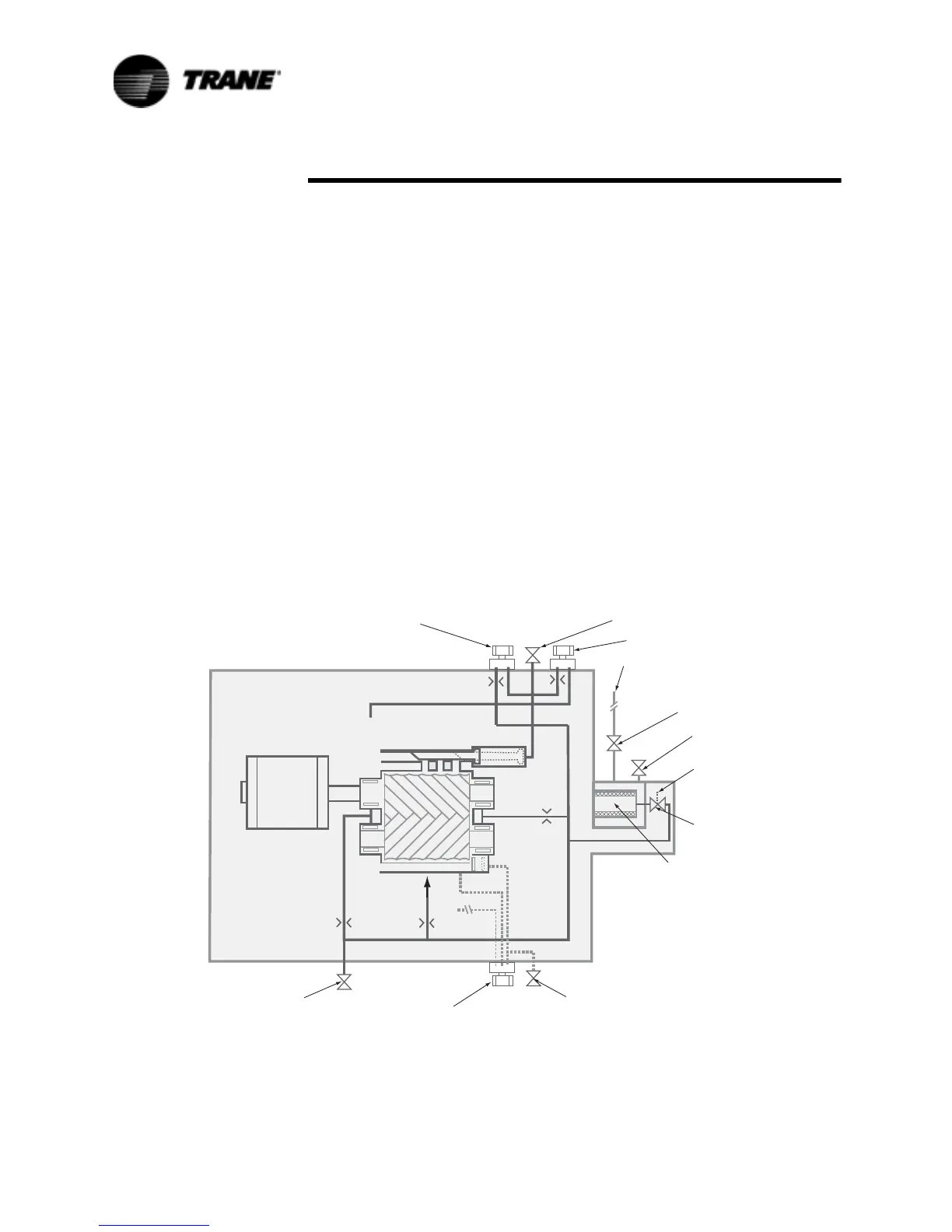

Compressor Rotors

The compressor is a semi-hermetic, direct-drive helical rotary type

compressor. Each compressor has two rotors - “male” and “female” - which

provide compression. See Figure 33 The male rotor is attached to, and driven

by, the motor, and the female rotor is, in turn, driven by the male rotor.

Separately housed bearing sets are provided at each end of both rotors.

The helical rotary compressor is a positive displacement device. The refrig-

erant from the evaporator is drawn into the suction opening at the end of the

motor barrel, through a suction strainer screen, across the motor, and into the

intake of the compressor rotor section. The gas is then compressed and

discharged directly into the discharge line.

There is no physical contact between the rotors and compressor housing.

The rotors contact each other at the point where the driving action between

the male and female rotors occurs. Oil is injected along the top of the

compressor rotor section, coating both rotors and the compressor housing

interior. Although this oil does provide rotor lubrication, its primary purpose is

to seal the clearance spaces between the rotors and compressor housing.

A positive seal between these internal parts enhances compressor efficiency

by limiting leakage between the high pressure and low pressure cavities.

Capacity control is accomplished by means of two unloader valve assemblies

in the rotor section of the compressor. The female rotor valve is a two-

position valve and the male valve is an infinitely variable position valve. See

Figure 33.

Figure 33 RTAA Refrigerant and Oil Diagram

6FKUDGHU

9DOYH

6FKUDGHU

9DOYH

6FKUDGHU9DOYH

6FKUDGHU

9DOYH

)HPDOH

8QORDGHU

6ROHQRLG9DOYH

0DVWHU

2LO9DOYH

'LVFKDUJH

3UHVVXUH

,QWHJUDWHG

2LO)LOWHU

4XLFN&RQQHFW6KXWRII

9DOYHRU$QJOH9DOYH

)URP2LO&RROHU

0DOH8QORDG

6ROHQRLG9DOYH

0DOH/RDG

6ROHQRLG

9DOYH

0DOH

)HPDOH

0RWRU

6XFWLRQ

6XFWLRQ

6XFWLRQ

7R5RWRU

2LO,QVSHFWLRQ

'LVFKDUJH

3UHVVXUH

Loading...

Loading...