RLC-SVX19G-GB

171

11UNT-PRC002-GB

Sound power levels

Discharge

Measurement conditions:

Measurements taken in a room adjacent to the room containing the FWD, at the outlet of the rectangular duct (1.5 m

long) fixed to its discharge opening.

Fan Power level in dB(A), per Hz frequency band Overall power

Unit speed 125 250 500 1000 2000 4000 8000 dB(A)

1 55 50 42 37 37 31 30 46

FWD 08 2 57 54 47 40 30 38 40 50

3 58 57 50 42 32 40 43 53

1 57 51 45 42 34 33 28 48

FWD 10 2 58 54 48 45 38 39 35 51

3 60 58 50 48 40 42 39 54

1 57 51 45 42 34 33 28 48

FWD 12 2 58 54 48 45 38 39 35 51

3 60 58 50 48 40 42 39 54

1 56 62 50 48 39 38 36 56

FWD 14 2 61 66 55 53 47 46 45 60

3 63 69 58 56 50 50 49 63

1 57 63 51 49 40 39 37 57

FWD 20 2 61 66 55 53 47 46 45 60

3 63 69 58 56 50 50 49 63

Intake

Measurement conditions:

Measurements taken at the horizontal air intake.

Fan Power level in dB(A), per Hz frequency band Overall power

Unit speed 125 250 500 1000 2000 4000 8000 dB(A)

1 56 55 55 53 46 45 42 57

FWD 08 2 63 62 60 60 53 53 53 64

3 66 65 63 62 56 55 57 67

1 62 58 55 58 51 48 44 61

FWD 10 2 66 63 60 62 56 55 52 66

3 70 67 63 65 59 59 57 69

1 62 58 55 58 51 48 44 61

FWD 12 2 66 63 60 62 56 55 52 66

3 70 67 63 65 59 59 57 69

1 66 65 65 65 57 50 46 68

FWD 14 2 73 72 69 71 64 59 57 74

3 78 76 73 75 69 64 63 78

1 68 72 64 64 56 52 50 69

FWD 20 2 76 76 68 71 65 61 61 75

3 78 79 71 74 69 66 66 78

Condenser Coils MCHE Maintenance

Cleaning Procedures

• It is mandatory to clean regularly the coils for a proper

unit operation. Eliminate pollution and other residual

material help to extend the life of the coils and the unit

CAUTION! Equipment Damage! Do not use coil cleaning

agents to clean uncoated RTAF coils. Use clean water

only. Use of coil cleaning agents on uncoated RTAF coils

could cause damage to coils.

• Regular coil maintenance, including annual cleaning-

enhances the unit’s operating efficiency by minimizing

compressor head pressure and amperage draw. The

condenser coil should be cleaned at least once each

quarter or more if the unit is located in a “dirty” or

corrosive environment. Unless it is the Trane cleaner

part reference CHM014E cleaning with cleansers or

detergents is strongly discouraged due to the all-

aluminum construction; straight water should prove

sufficient.

Important: Only in extreme cases should any type of

chemical cleaner or detergent be used on microchannel

coils. If it becomes absolutely necessary because water

alone did not clean the coil, specify a cleaner that is:

• A is pH neutral cleaner.

• An alkaline cleaner that is no higher than 8 on the

pH scale.

• An acidic cleaner that is no lower than 6 on the

pH scale.

• Does not contain any hydrofluoric acids.

Be sure to follow the instructions provided with any

cleaner chosen. Keep in mind that it is still MANDATORY

that the coils are thoroughly rinsed with water after the

application of the cleaner even if the instructions specify

a “No Rinse” cleaner. Cleaners or detergents that are

left on the coil due to improper rinsing will significantly

increase the possibility of corrosion damage on the

microchannel coil.

Note: Quarterly cleaning is essential to extend the life

of an E-coated coil and is required to maintain warranty

coverage. Failure to clean an E-coated coil will void

the warranty and may result in reduced effi ciency and

durability in the environment.

WARNING! Hazardous Voltage!

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. Failure to disconnect power

before servicing could result in death or serious injury.

1. Disconnect Power to the unit.

2. Wear proper personal protection equipment such as

a face shield, gloves and waterproof clothing.

3. Remove enough panels from the unit to gain safe

access to the microchannel coil.

Note: It is better to clean the coil from the opposite

direction of normal air flow (inside of unit out) because

this allows the debris to be pushed out rather than

forced further into the coil.

4. Use a soft brush or vacuum to remove base debris or

surface loaded fibers from both sides of the coil.

5. Using a sprayer and water ONLY, clean the coil

following the guidelines below.

a. Sprayer nozzle pressure should not exceed

40 bars.

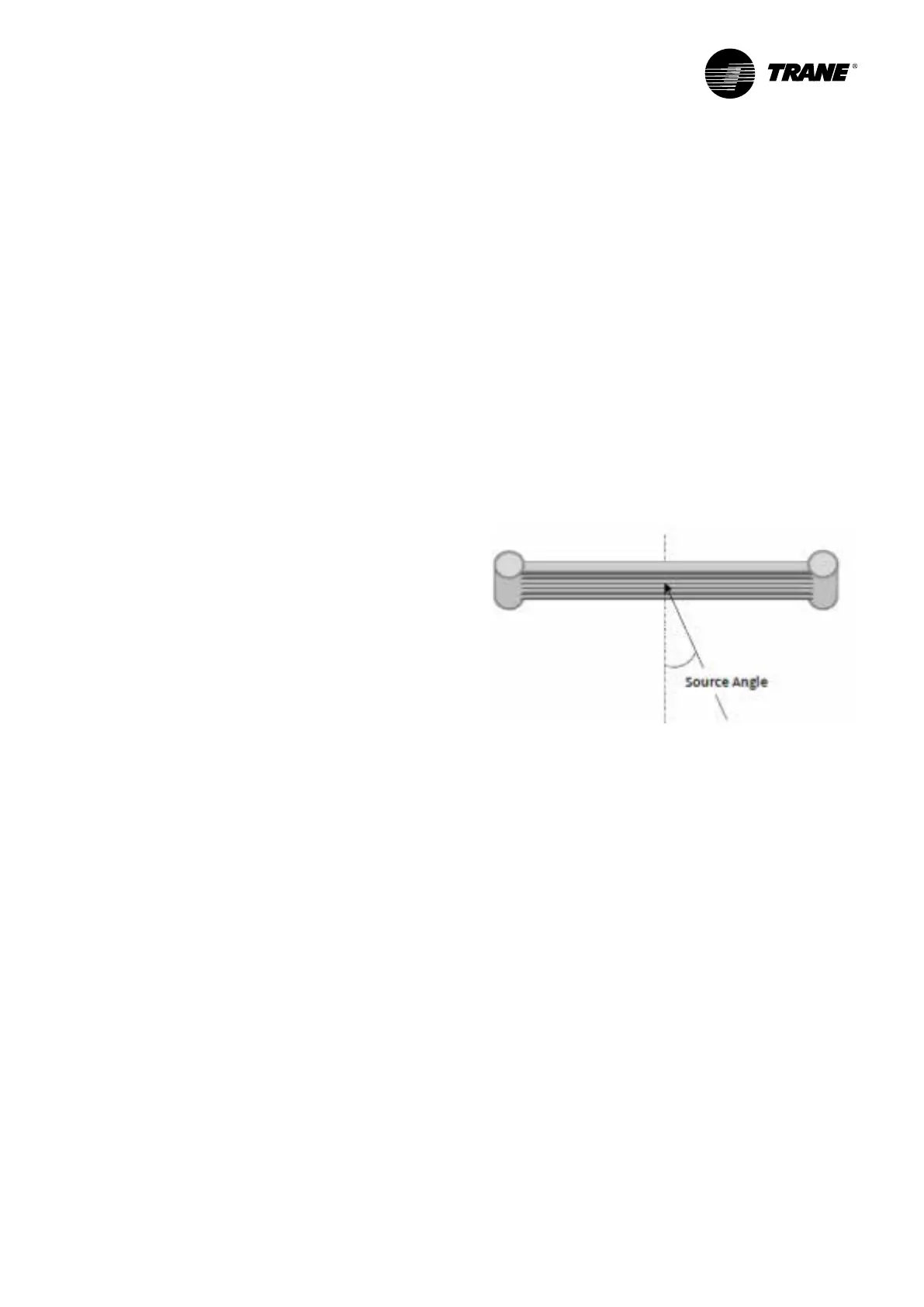

b. The maximum source angle should not exceed

25 degrees (Figure 22) to the face of the

coil. For best results spray the microchannel

perpendicular to face of the coil.

c. Spray nozzle should be approximately 5 to 10 cm

from the coil surface.

d. Use at least a 15º fan type of spray nozzle.

Figure 40 – Sprayer source angle

To avoid damage from the spray wand contacting the

coil, make sure the 90º attachment does not come in

contact with the tube and fin as abrasion to the coil

could result.

Repair/Replacement of

Microchannel Coil

Microchannel coils are considerably more robust in

design than tube and fin condenser coils, however they

are not indestructible. When damage or a leak occurs in

the field, it is possible to temporarily repair the coil until

another coil can be ordered.

If the leak is found to be within the tube area of the coil,

a field repair kit (KIT16112) is available through your

local Trane parts center. Because of the all-aluminum

construction and aluminum’s high thermal expansion

rate, a leak located at or on the header assembly cannot

be repaired.

Loading...

Loading...