Connectine Rod

insert the nev:. Ensure that the oilw-j.; are aligned. When reamering the bush.

care must be taken to ensure that the bore is parallel with the big-end.

The final examination

is

the

fit

of the main bearings on the crank timing and driving

shafts. The bearings should be a tight push

fit

;

a loose fitting bearing would tend

to cause crankcase "rumble".

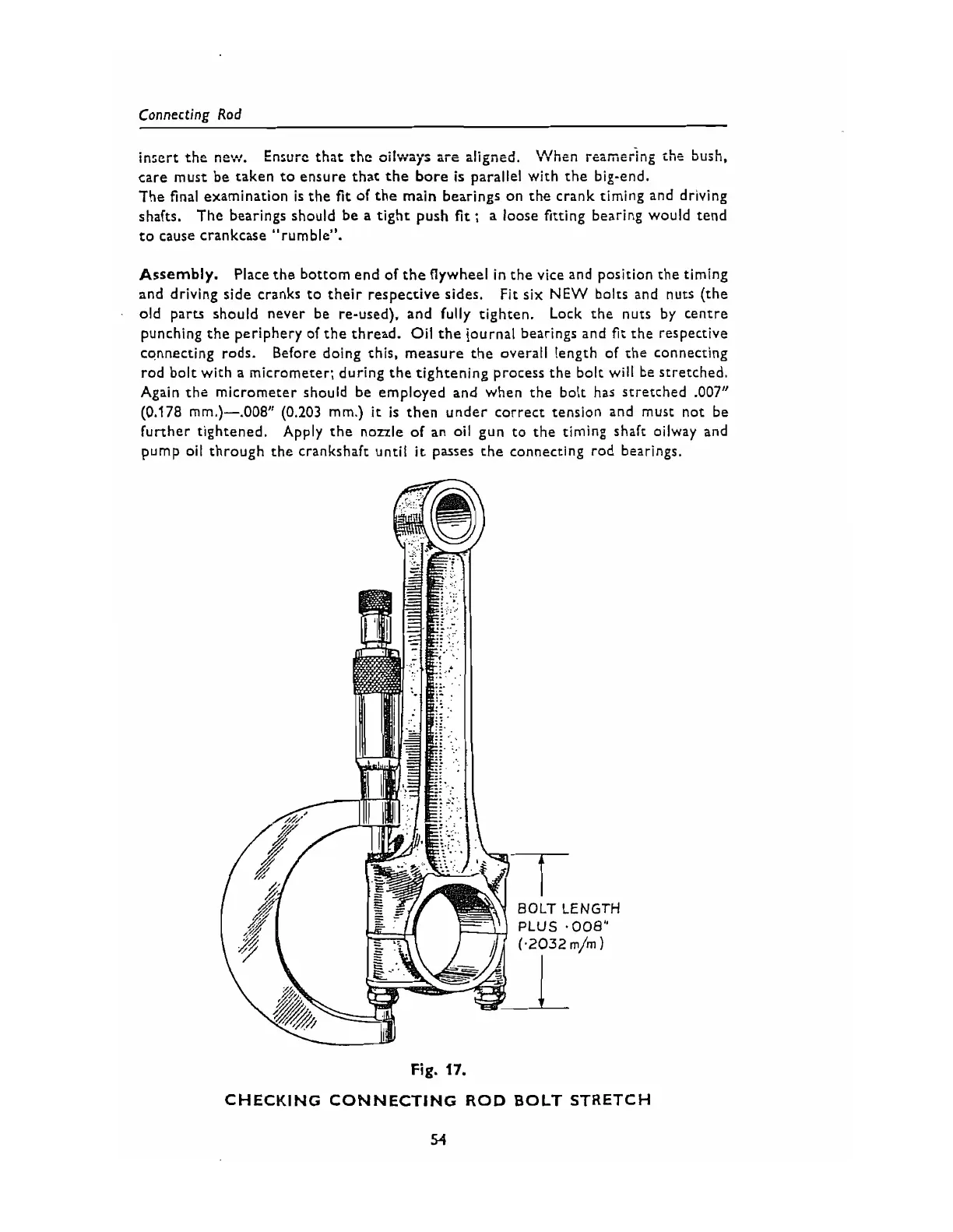

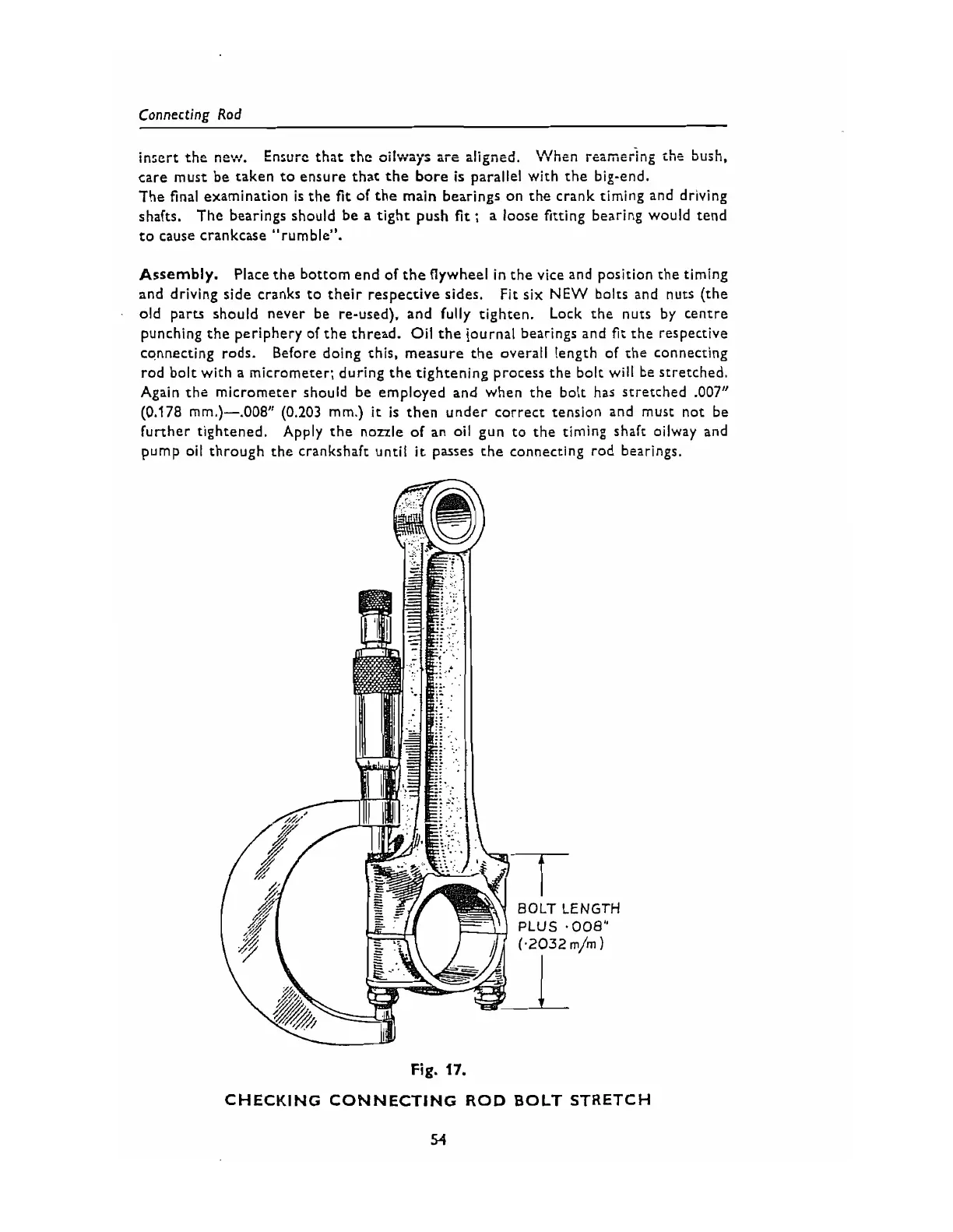

Assembly. Place the bottom end of the flywheel in the vice and position the timing

and driving side cranks to their respecrive sides. Fit six

NEW

bolts and nuts (the

old parts should never be re-used), and fully tighten. Lock the nuts by centre

punching the periphery of the thread.

Oil

the journal bearings and tit the respective

connecting rods. Before doing this, measure the overall length of the connecting

rod bolt with a micrometer; during the tightening process the bolt

will be stretched.

Again the micrometer should be employed and when the bolt has stretched ,007"

(0.178 mm.)-.008" (0.203 mm.)

it

is then under correct tension and must not be

furrher tightened. Apply the nozzle of an

oil

gun to the timing shalt oilway and

pump oil through the crankshaft until

it

passes the connecting rod bearings.

T

BOLT

LENGTH

PLUS

.008"

(.2032

m/rn

)

I

Fig.

17.

CHECKING CONNECTING ROD BOLT STRETCH

Loading...

Loading...