High

Gear,

Oil

Seal and Mainshaft Bearing.

Remove the two long casing to

outer cover studs and the two dowels, casing to inner cover and press the high gear

out and into the casing. Ease the oil seal from the housing and discard.

I

/I

Remove the bearing retaining circlip and press the bearing out of the housing.

Check the gear for chipped or worn teeth and the shaft bearing for wear. Thoroughly

clean and degrease the journal bearing and dry with pressure air. Check for rough-

ness, pitting, indentation and float; make sure that the mainshaft high gear is a good

fit

in the inner race. When replacing, first warm the casing and then press the

bearing into the hous~ng, securing

it

with a circlip. Lubricate with oil when in

posit~on. Press a new

011

seal into the ball race housing with the part number on

the outside and the leather "rolling" towards the inside of the case. Insert the

high gear from inside the housing, through the bearing and press

it

fuliy:home.

Replacing the Chain Sprocket

and

Nut.

Support the high gear from inside the

casing and press the sprocket onto the high gear splines. Secure the casing in the

vice and with a block between the sprocket teeth and the vice, tighten the locknut

to the sprocket.

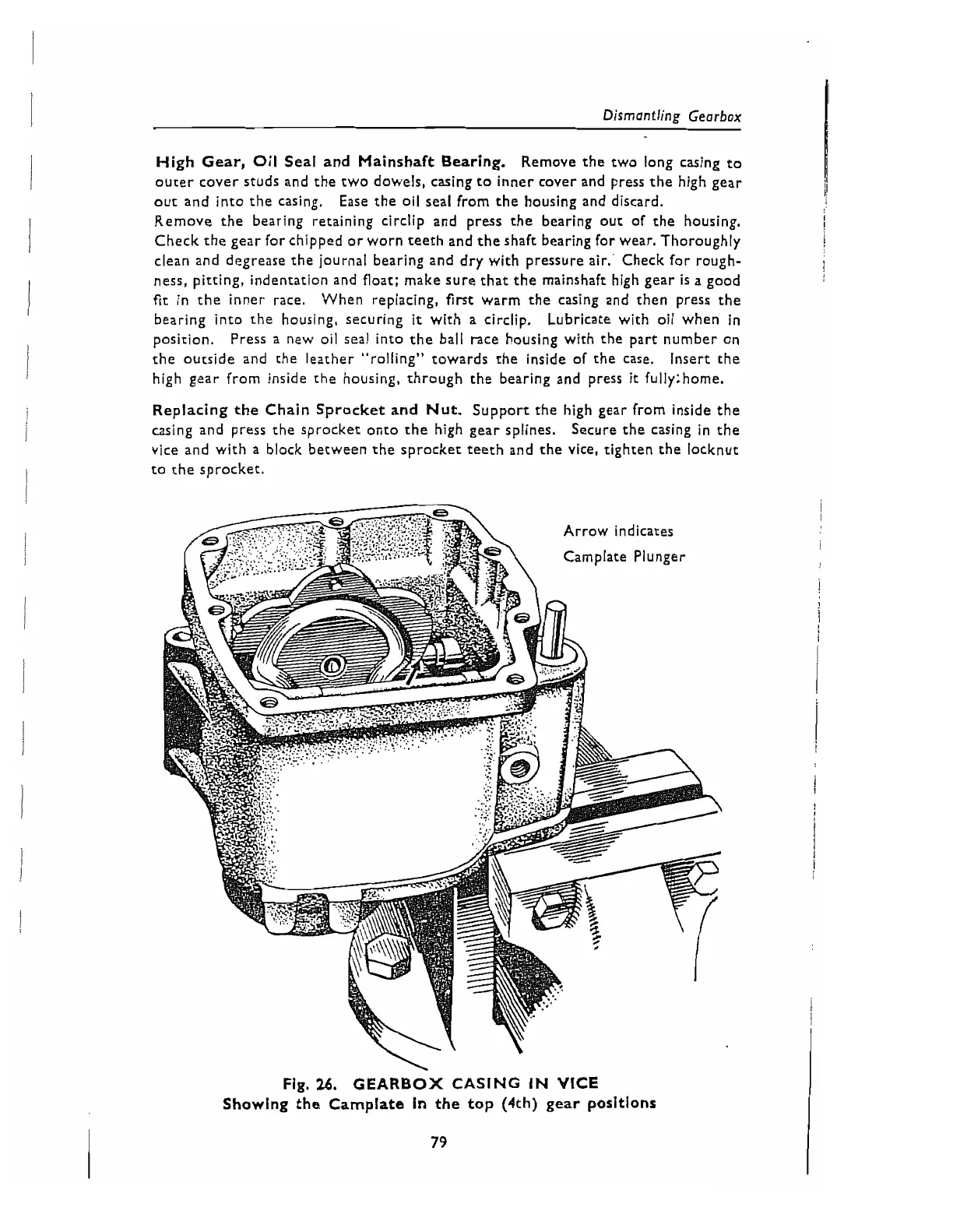

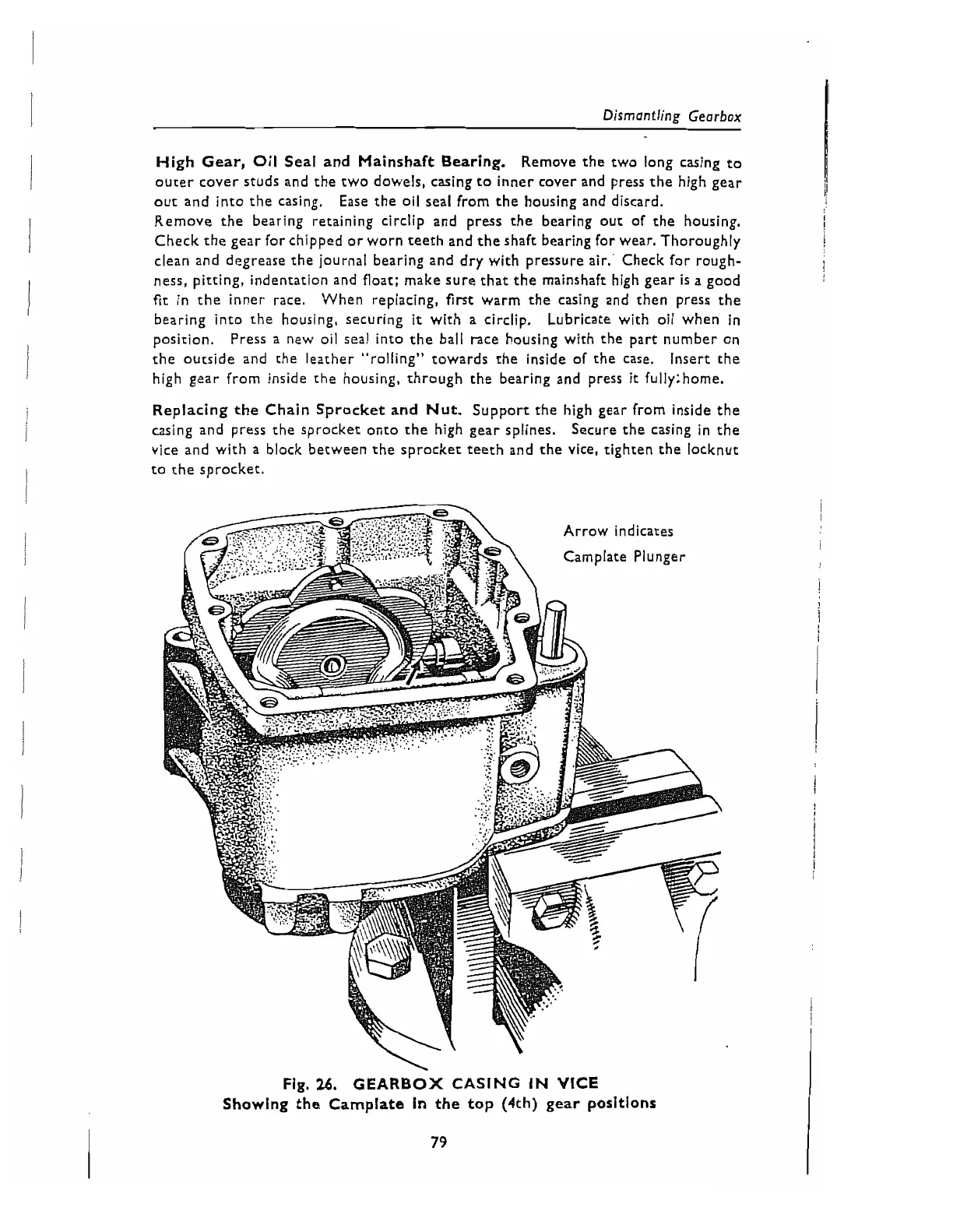

Arrow indicates

Camplate Plunger

Fig.

26.

GEARBOX CASING

IN

VICE

Showing the Carnplate

in

the top (4th) gear positions

Loading...

Loading...