DISMANTLING. PREPARATION AND ASSEMBLY

OF

UNITS

GEARBOX OUTER COVER

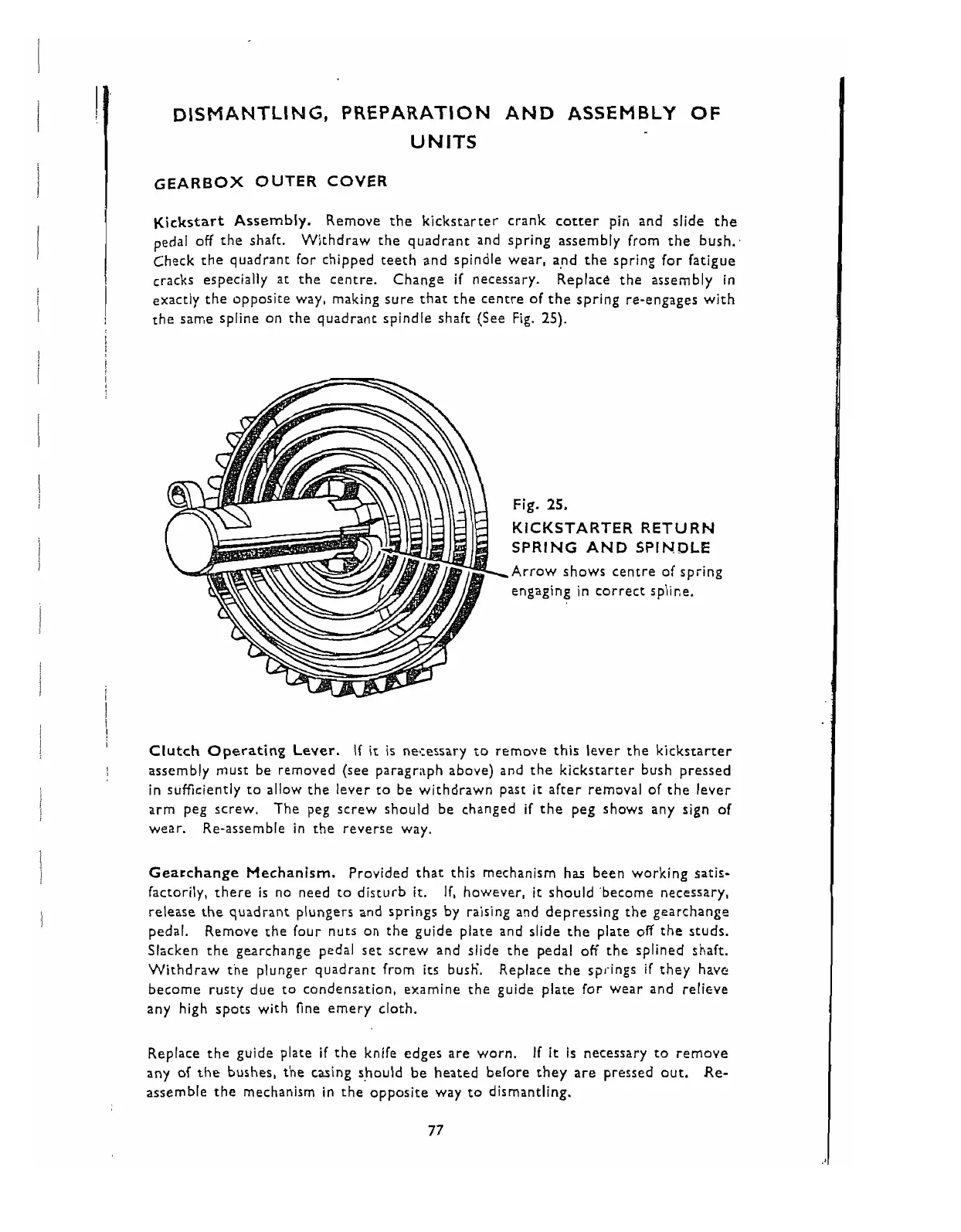

Kickstart Assembly. Remove the kickstarter crank cotter pin and slide the

pedal off the shaft.

Withdraw the quadrant and spring assembly from the bush.

Check the quadrant for chipped teeth and spindle wear, and the spring for fatigue

cracks espec~ally at the centre. Change if necessary.

Replace the assembly in

exactly the opposlte way, making sure that the centre of the spring re-engages with

the same spline on the quadrant spindle shaft (See Fig.

25).

Fig.

25.

KICKSTARTER RETURN

SPRING

AND

SPINDLE

.Arrow shows centre of spring

engaging in correct spline.

I

1

Clutch Operating Lever.

If

it

is necessary to remove this lever the kickstarter

i

assembly must be removed (see paragraph above) and the kickstarter bush pressed

1

in sufficiently to allow the lever to be withdrawn past

it

after removal of the lever

i

arm peg screw.

The peg screw should be changed if the peg shows any sign of

wear. Re-assemble in the reverse way.

Geacchange Mechanism. Provided that this mechanism has been working satir-

factorily, there

is

no need to disturb

it.

If, however,

it

should 'become necessary,

release the quadrant plungers and springs by raising and depressing the gearchange

pedal. Remove the four nuts on the guide plate and slide the plate off the studs.

Slacken the gearchange pedal set screw and slide the pedal off the splined shaft.

Withdraw the plunger quadrant from its

busfi.

Replace the springs if they have

become rusty due to condensation, examine the guide plate for wear and relieve

any high spots with

fine emery cloth.

1

Replace the guide plate if the knife edges are worn.

If

it

is necessary to remove

any of the bushes, the casing should be heated before they are pressed out.

Re-

assemble the mechanism in the opposite way to dismantling.

I

Loading...

Loading...