Chapter 2 Installation Instruction 3

NetSure 531 A41, NetSure 531 A91 Subrack Power system User Manual

Chapter 2 Installation Instruction

2.1 Safety Regulations

Certain components in this power system have hazardous voltage and current. Always follow the instructions below:

1. Only the adequately trained personnel with satisfactory knowledge of the power system can carry out the

installation. The most recent revision of these safety rules and local safety rules in force shall be adhered to during

the installation.

2. All external circuits that are below 48V and connected to the power system must comply with the requirements of

SELV as defined in IEC 60950.

3. Make sure that the power (mains and battery) to the system is cut off before any operations can be carried out

within the system subrack.

4. The power subrack shall be kept locked and placed in a locked room. The key keeper should be the one

responsible for the power system.

5. The wiring of the power distribution cables should be arranged carefully so that the cables are kept away from the

maintenance personnel.

2.2 Preparation

Unpacking inspection

The equipment should be unpacked and inspected after it arrives at the installation site. The inspection shall be done

by representatives of both the user and Vertiv Tech Co., Ltd.To inspect the equipment, you should open the packing

case, take out the packing list and check against the packing list that the equipment is correct and complete. Make

sure that the equipment is delivered intact.

Cables

The cable design should meet relevant industry standards.

It is recommended to use the RVVZ cables as AC cables. The cable should reach at least +70°C temperature

durability. With cable length shorter than 30 meters, the Cross-Sectional Area (CSA) calculation should be based on

the current density of 3.5A/mm

2

. The suggested CSA value is no less than the Table 2-1.

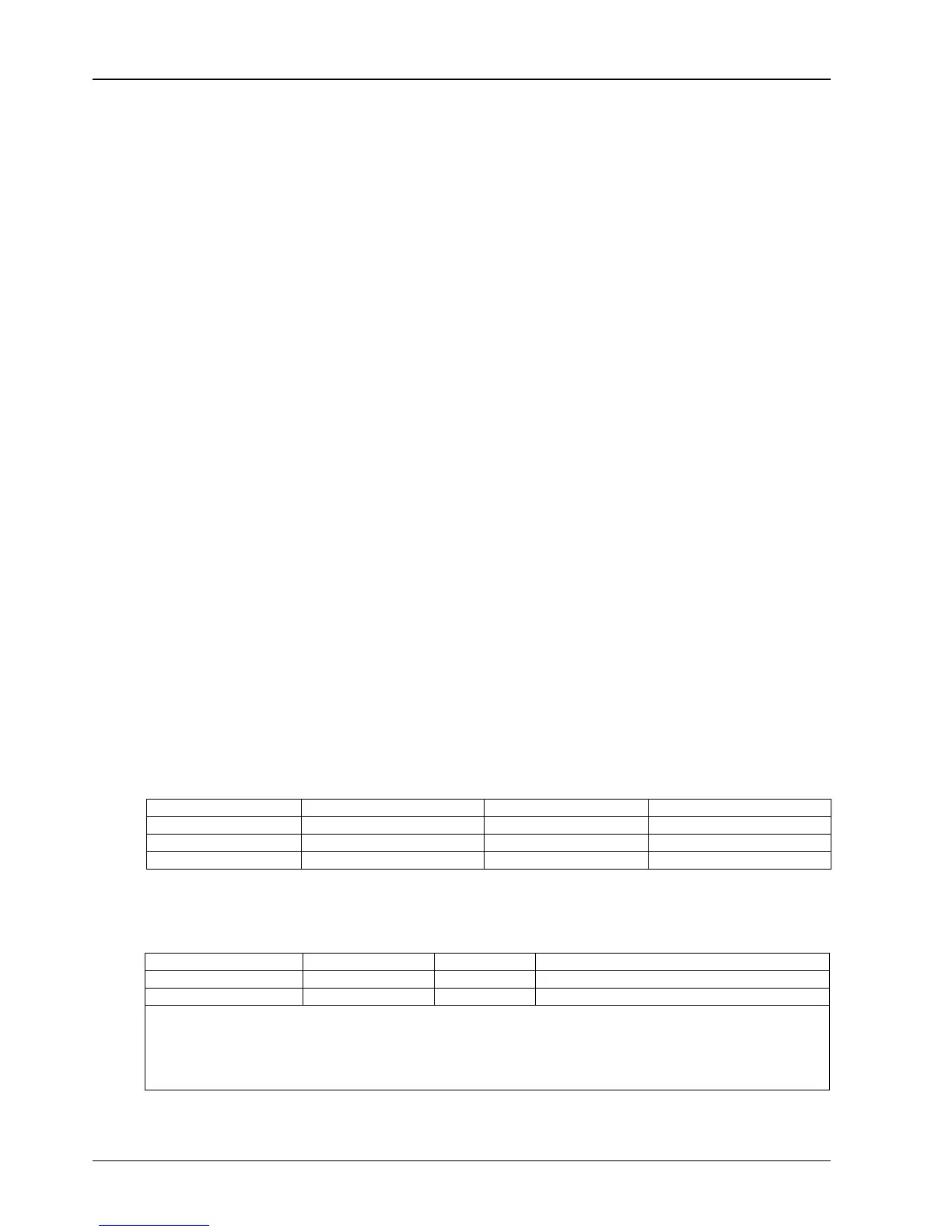

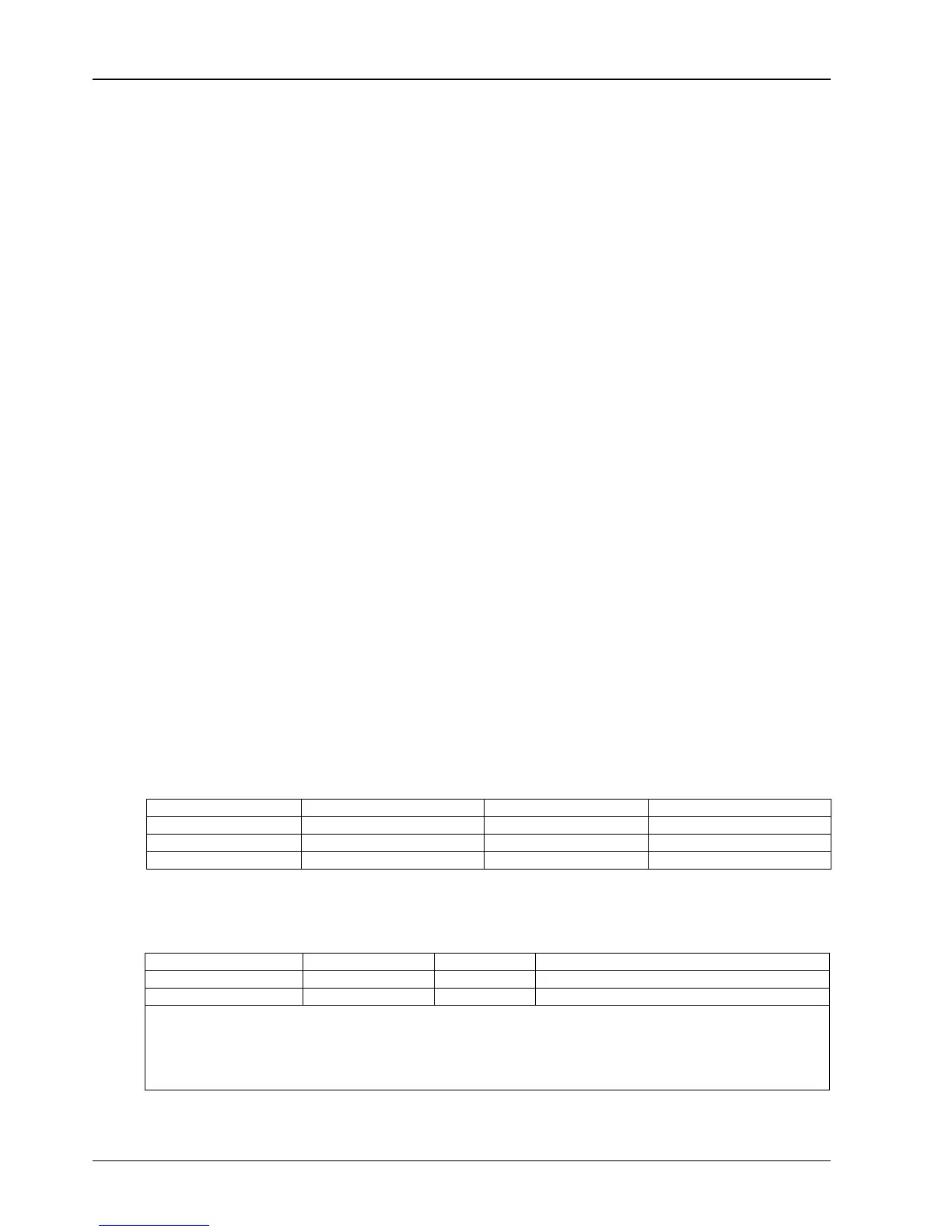

Table 2-1 Load cable CSA selection

Note:

1. The specs are applicable at ambient temperature of 25°C. If the temperature is higher than this, the CSA of the cable should

be increased.

2. The battery cable should reach at least +90°C heat durability. It is recommended to use double-insulated copper-core flame

retardant cable as battery cable

Loading...

Loading...