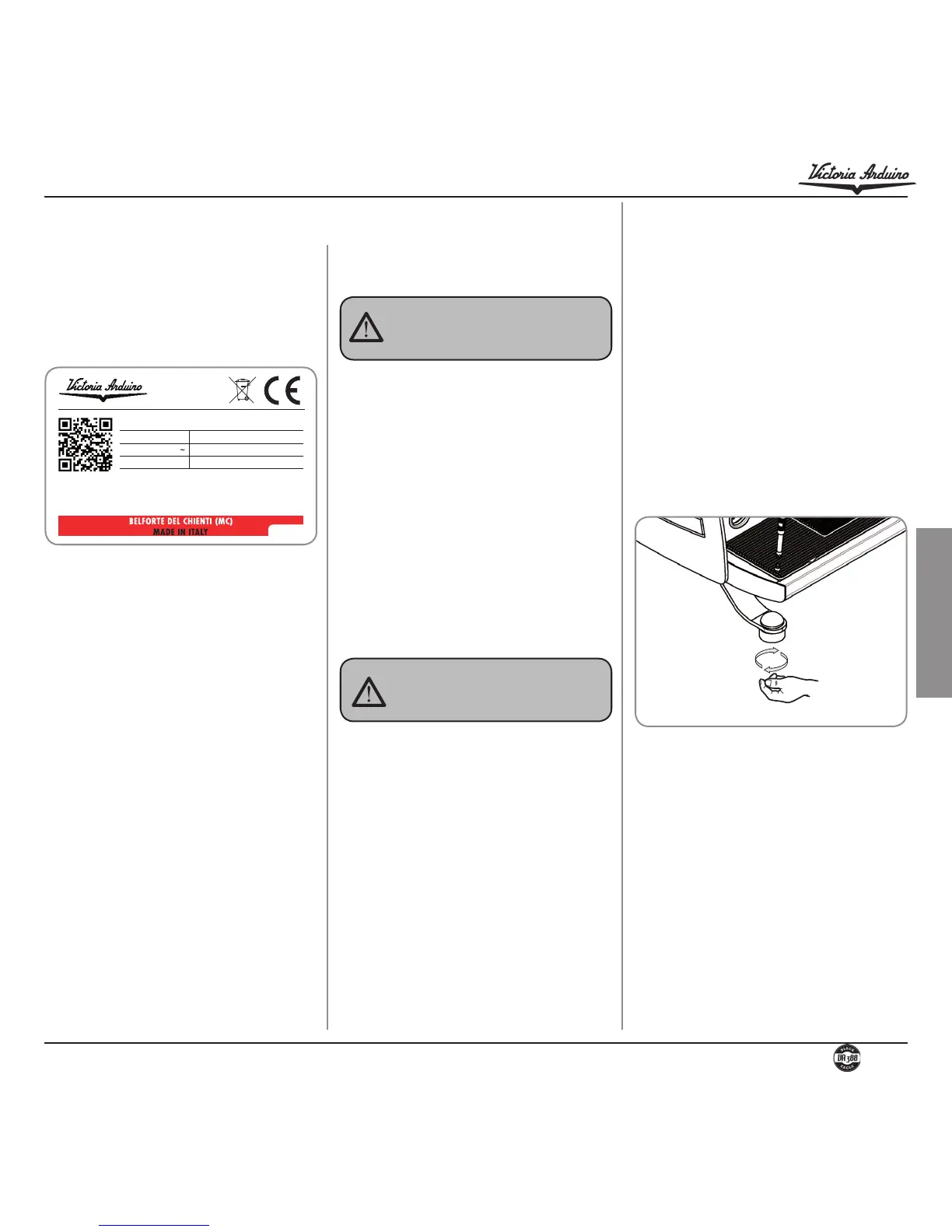

Once the machine is out of the packaging and

its integrity, and that of the accessories has

been checked, place it on a flat, horizontal

surface and if necessary, use the adjustable

feet to make sure it is correctly level:

7XUQWKHIHHWWRWKHOHIWWRUDLVHWKHPDFKLQH

up to a maximum of + 1 cm;

7XUQ WKH IHHW WR WKH ULJKW WR ORZHU WKH

machine.

It is advisable to install a softener (1) and then

a mesh filter (2) on the external part of the

plumbing system, during preliminaries and after

levelling the machine.

Fig. 10

4. INSTALLATION

AND

PRELIMINARY

OPERATIONS

Always quote the machine serial number in all

communications to the manufacturer, Victoria

Arduino.

The machine is transported on pallets which

also contain other machines - all boxed and

secured to the pallet with supports.

Before carrying out any transport or handling

operation, the operator must:

SXWRQZRUNJORYHVDQGSURWHFWLYHIRRWZHDU

as well as a set of overalls which must be

elasticated at the wrists and ankles.

The pallet must be transported using a suit-

able means for lifting (e.g., forklift).

CAUTION

RISK OF IMPACT

OR CRASHING

CAUTION

RISK OF IMPACT

OR CRASHING

Must ensure that there are no persons,

objects or property in the handling area.

The pallet must be slowly raised to a height

of 30 cm (11,8 in) and moved to the loading

area. After first ensuring that there are no

persons, objects or property, loading opera-

tions can be carried out.

Upon arrival at the destination and after

ensuring that there are no persons, objects

or property in the unloading area, the prop-

er lifting equipment (e.g. forklift) should be

used to lower the pallet to the ground and

then to move it (at approx. 30 cm (11,8 in)

from ground level), to the storage area.

Before carrying out the following operation,

the load must be checked to ensure that it is

in the correct position and that, when the

supports are cut, it will not fall.

The operator, who must first put on work

gloves and protective footwear, will proceed

to cut the supports and to storing the prod-

uct. To carry out this operation, the techni-

cal characteristics of the product must be

consulted in order to know the weight of the

machine and to store it accordingly.

3. TRANSPORT AND HANDLING

3.1 MACHINE

IDENTIFICATION

3.2 TRANSPORT

3.3 HANDLING

Mod. VA388 T3 S GR2 C

Operating Pressure 0,165 MPa MAX Inlet Pressure 0,65 Mpa

S.N. XXXXXX Date 09 / 03 /2015

Cup Warmer

P = 7400 W

380 - 415 V3N

50 / 60 Hz

Since 1905

Fig. 9

Loading...

Loading...