G 2.5A Portable Generator Repair

wc_tx000207gb.fm 44

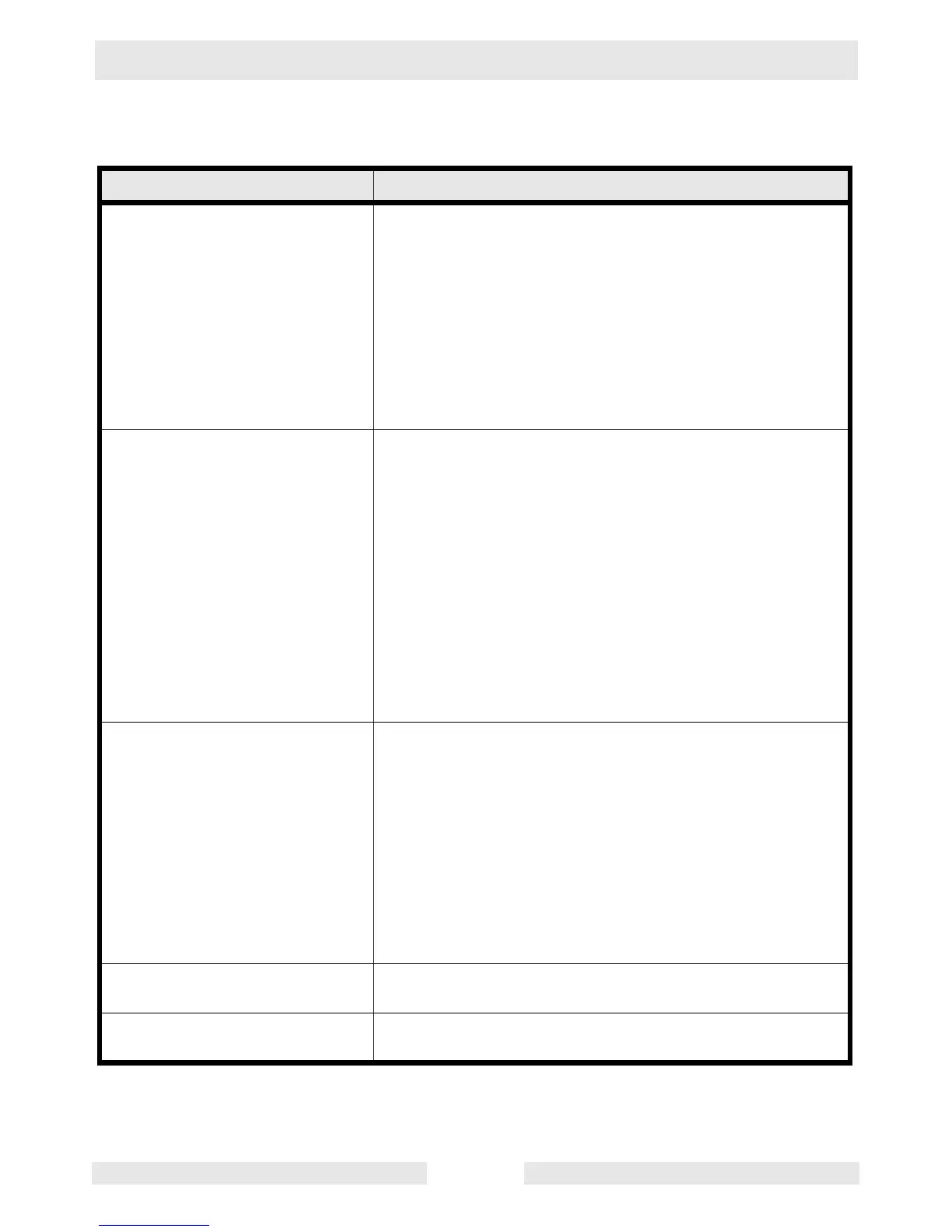

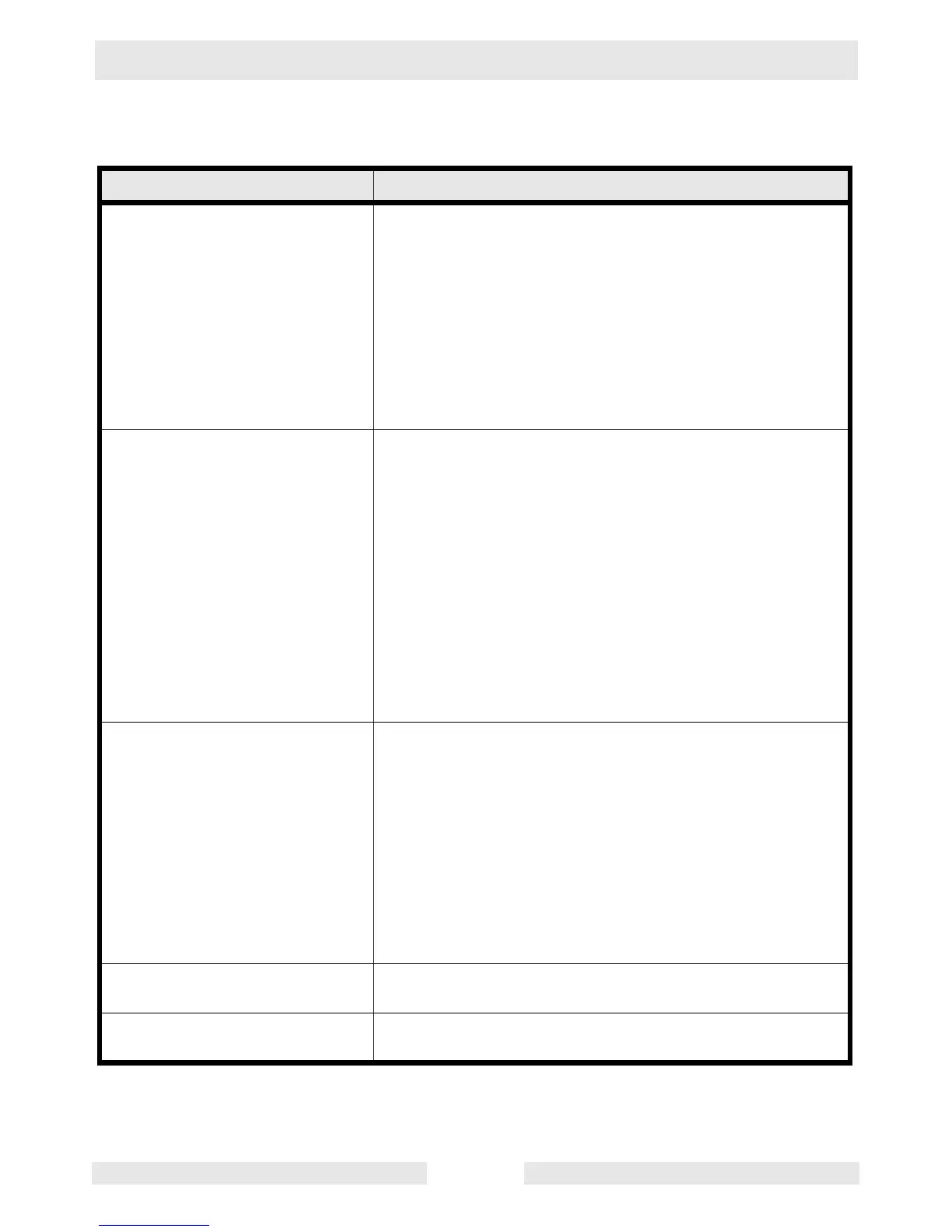

5.17 Troubleshooting

Problem / Symptom Reason / Remedy

Engine Does Not Start • Engine switch is in “OFF” position. Move engine switch to

“START” position.

• Fuel valves under fuel tank and on engine are closed. Open

fuel valves.

• Fuel tank is empty. Fill fuel tank.

• Choke lever is in wrong position. Move choke lever to correct

position. (Close choke lever when starting a cold engine).

• Spark plug is in poor condition. Replace spark plug.

• Spark plug cap is loose. Tighten spark plug cap.

• Engine oil level is low. Refill oil.

No Output Voltage • Engine speed too slow. Increase engine speed to 3700 rpm,

no-load.

• Circuit breaker open. Reset breaker.

• GFI open. Test and reset GFI. Replace if defective. Tool or

appliance defective, leaking current.

• Loss of residual magnetism. Flash rotor fields.

• Defective receptacle or switch. Inspect wiring and components

and repair.

• Rotor diodes open or shorted. Test diodes and replace.

• Open or shorted stator windings. Test stator and replace.

• Open or shorted rotor windings. Test rotor and replace.

• Connector from generator to control panel is loose or discon-

nected. Install tightly.

Low Voltage • No-load voltage between 70 – 100 volts, engine operating at

correct speed. One diode on rotor open or shorted. Replace all

diodes.

• Engine slightly below operating speed, but not enough to col-

lapse all output. Increase engine speed to 3700 rpm, no-load.

• Capacitor is defective. Test capacitor and replace if necessary.

• Rotor winding wire broken off at diode. Resolder wire to diode.

• Rotor winding partially shorted. Test rotor winding resistance.

Replace rotor.

• Rotor slipping on engine crankshaft. Rotor winding partially

shorted.

High Voltage • Engine speed too high. Reduce engine speed to 3700 rpm, no-

load.

No-load Voltage Normal but Falls

when Load is Applied

• Engine lugging down under load. Refer to engine repair manual

to restore engine power.

Loading...

Loading...