44 HC920•HC940•HC960

Interruption of work Cleaning the unit (shutting down)

9. Move the hydraulic ball valve on the material feed pump to

its horzontal position (closed).

10. Turn off the gasoline engine or electric motor.

8.1 Cleaning the unit from the outside

Danger

Gasoline units — Switch off the gasoline engine

and let it cool down.

Electric units — Unplug the mains plug from the

socket.

Danger

Danger of short-circuits through penetrating

water.

Never spray down the unit with high-pressure or

high-pressure steam cleaners.

Wipe the unit off with a cloth soaked in a suitable cleaning agent.

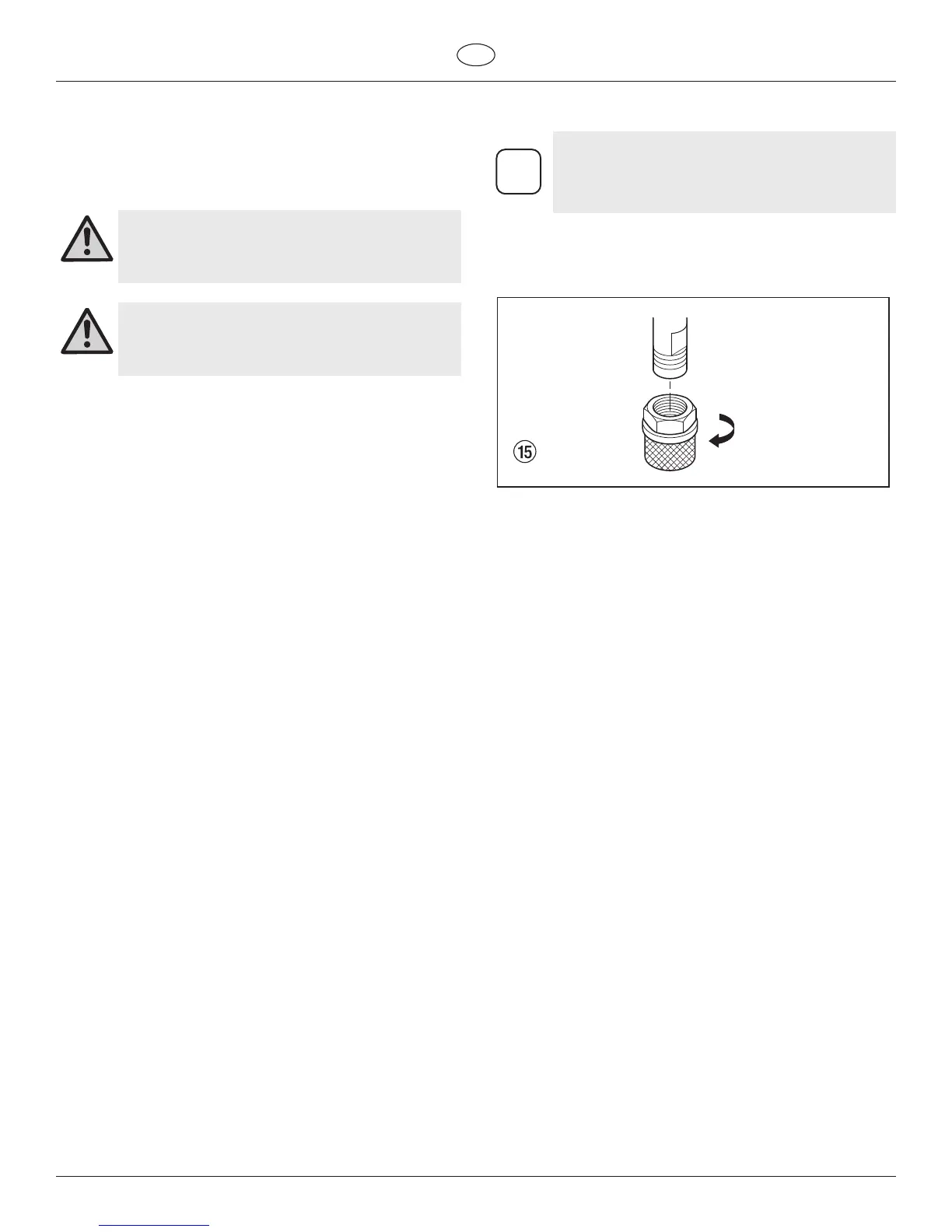

8.2 Suction lter on HC 920

i

A clean suction lter always guarantees maximum

feed quantity, constant spraying pressure and

problem-free functioning of the unit.

– Screwoffthelter(g.15)fromsuctionpipe.

– Cleanorreplacethelter.

Carry out cleaning with a hard brush and an appropriate

cleaning agent.

8.3 Cleaning the high-pressure lter

Cleantheltercartridgeregularly.

Asoiledorcloggedhigh-pressureltercancauseapoorspray

pattern or a clogged tip.

Disassembly

1. Move the hydraulic ball valve on the material feed pump to

its horzontal position (closed).

Flow of hydraulic oil to hydraulic motor of material feed

pump is interrupted.

2. Turn the relief valve handle (3) fully counterclockwise (k

Circulation).

3. Turn off the gasoline engine or electric motor.

4. Unscrewthehousingcover(g.16,item1).

5. Pullltercartridge(3)outofhousing(8).

6. Cleanthepressurespring(2)andltercartridge(3)with

an appropriate cleaning agent, clean the inside of the

housing (8) and housing cover (1).

7. Checkballintheltercartridge(3)forwearandreplace

ltercartridge,ifnecessary.

8. Ifballinltercartridge(3)isthoroughlyworn,aremove

O-ring (6) and valve seat (7). Replace worn valve seat, if

necessary.

9. Always replace O-ring (6) after removal.

10. Pull off pressure spring (2) from housing cover (1).

Measure length of pressure spring, and replace if shorter

than 19 mm.

Loading...

Loading...