Page 31

3.3 Unpacking

The unit is supplied on a small pallet and is covered with a cardboard box. The cardboard box

should be removed to reveal the unit with the supplied components located in the recessed

back panel. The unit is attached to the pallet using screws. These must be removed before

trying to remove the unit from the pallet. The unit can then be slid off the pallet and located into

position. Care should be taken to ensure that the unit does not tilt more than 45° when being

moved around as this can cause internal damage.

3.4 Heating Circuit Connection

3.4.1 Heating Medium

The heating system should be completely flushed to remove impurities and deposits from

sealants and fluxes. The heating circuit should be flushed, purged and pressure tested

according to MCS guide MIS3005 and to the relevant Building Regulations. An inhibitor should

be added to the water to prevent corrosion, scale and bacteria growth. This should be added

according to the inhibitor manufacturer’s guidelines. Glycol should be added to the system in

areas where the ambient temperature drops below freezing. The amount of Glycol to be added

should be determined according to the manufacturer’s instruction. Warmflow provide a non-

toxic glycol solution complete with corrosion, scale and biological inhibitor.

3.4.2 Heating Connections to the Heat Pump

The unit comes with female union fittings for the heating flow and return connections. Two

flexible hoses with connections to attach to the female unions are included with the unit. These

should be used to reduce any vibration or noise which may be transferred to rigid pipe or the

building structure.

3.4.3 Heating Circuit and Integrated Circulator

A variable speed high efficiency circulator for the heating circuit is provided within the casing of

each unit. The circulators have been sized to accommodate the majority of heating systems

based on the heat output of each unit. However, due to the variation in each system, checking

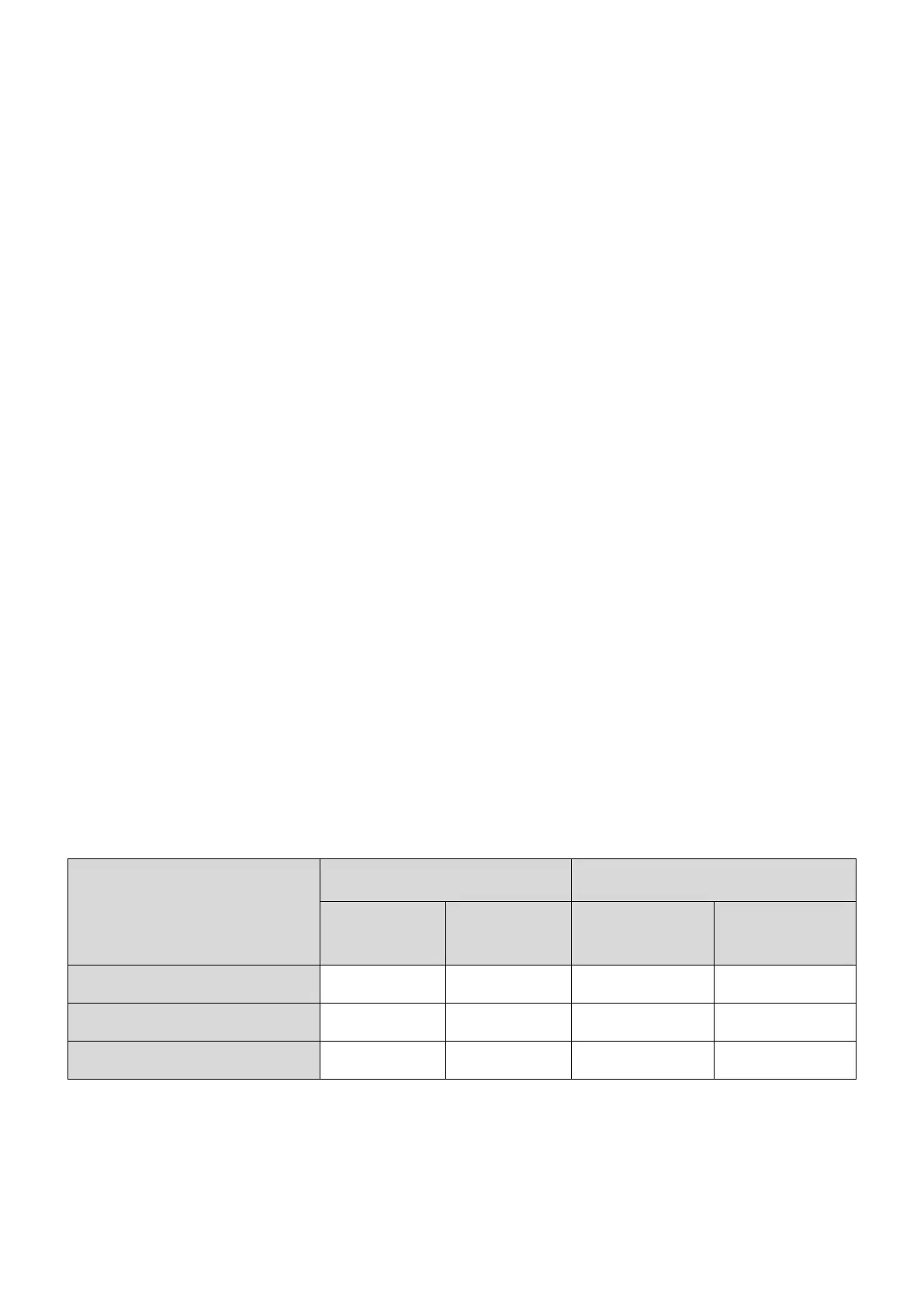

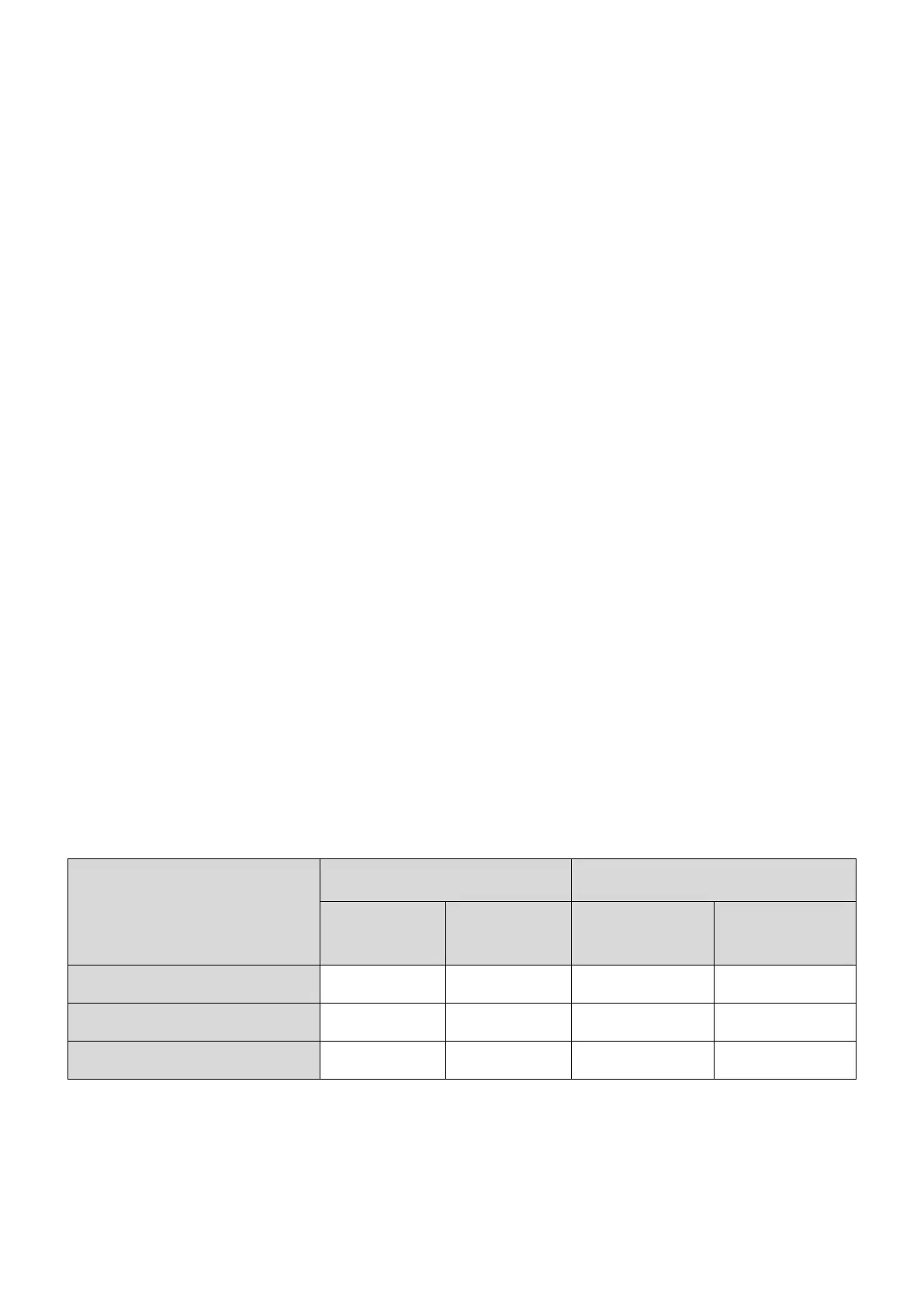

that the minimum required flow rate is achievable is essential. The table below shows the

minimum and maximum required flow rates for each unit at minimum and maximum heat

outputs respectfully.

Table 6 Heating flow rate requirements

Required Flow Rate (l/min)

3.4.4 Bypass / Open Zones

It is essential that the heating circuit can always achieve a minimum flow rate of at least 10 litres

per minute even when no zones are calling for heat. This can be achieved by fitting a bypass

between the flow and return or by leaving a number of zones/radiators permanently on. This

Loading...

Loading...