Specialized Concentrated Focused

Wiring「17」

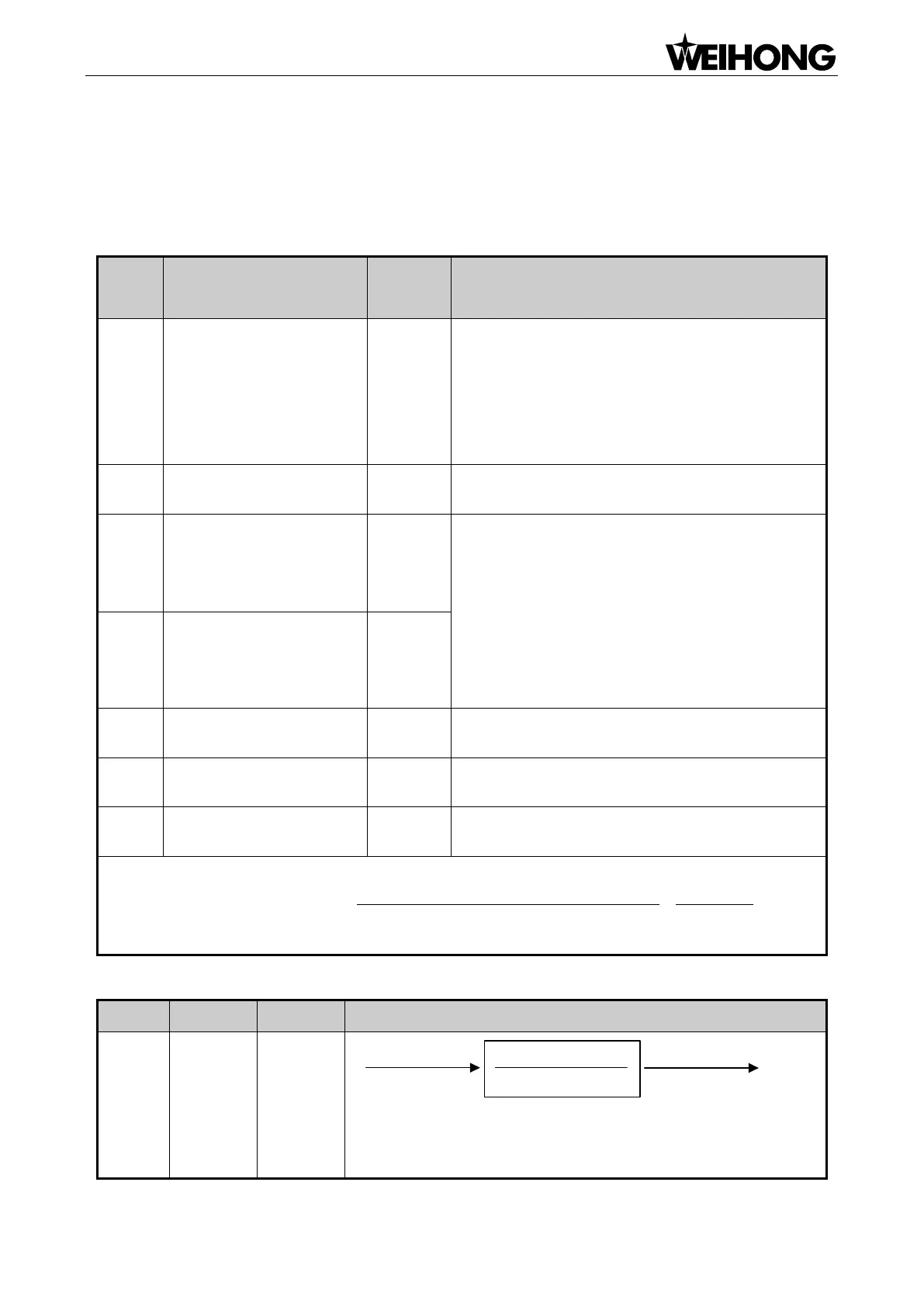

3.6 Parameter Setting of Servo Drivers

3.6.1 Parameter Setting of WISE Servo Driver

Monitor if the number of sent and received pulses

is correct by setting this parameter. In Weihong

control system, the correct quantity of pulses sent

by control card is detected by pulse inspection in

order to determine whether there is electrical

interference.

Command pulse No. per

motor circle

When it is set to “0”, parameters Pr009 and Pr010

are valid.

1

st

numerator of

command pulse

frequency division/

multiplication

Range: 0~2

30

Typical value: pitch 5 mm, encoder resolution

10000, deceleration ratio 1:1, pulse equivalent

0.001 mm:

Pr009=10000

Pr010=pitch 5mm/ pulse equivalent 0.001mm=

5000

Pr009/Pr010=10000/5000=2/1

Denominator of command

pulse frequency

division/multiplication

Unit: 0.1/s. Set it according to the actual situation.

Unit: 0.1Hz. Set it according to the actual

situation.

1st velocity loop

integrated time constant

Unit: 0.1ms. Set it according to the actual

situation.

When the value of Pr008 is not “0”, it can be calculated in terms of the following formula:

Screw pitch 5mm

Command pulse No. per motor circle 5000

Pulse equivalent Mechanical deceleration ratio 0.001mm/ p

When screw pitch is 5mm and pulse equivalent 0.001, the value of Pr008 is “5000”.

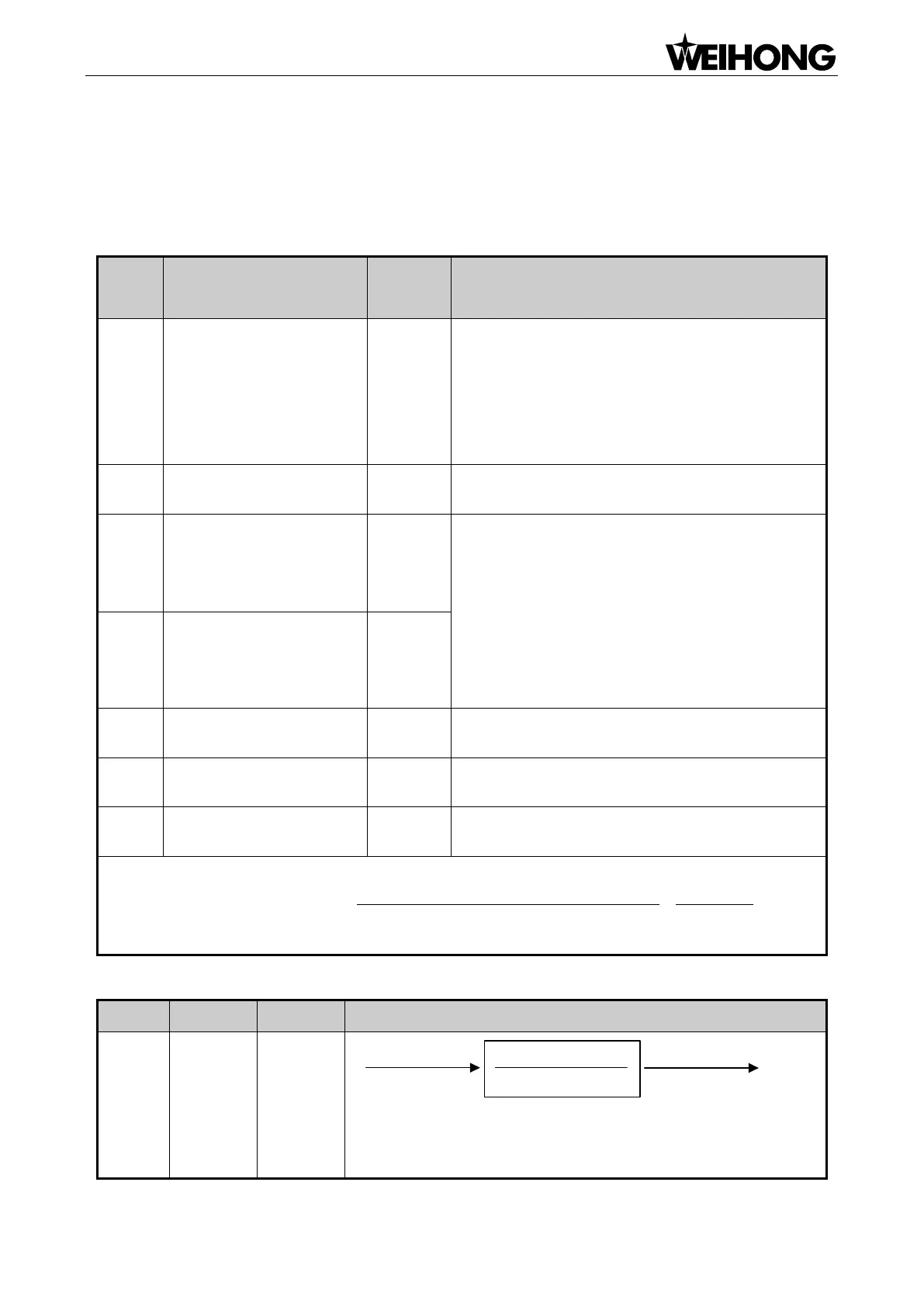

Attached Table: relationship among parameters Pr008, Pr009 and Pr010

Command

Pulse Input

Position

Command

Encoder Resolution

Setting Value of Pr008

As shown above, the process is undergone in terms of the

setting value of Pr008, not affected by the settings of Pr009 and

Pr010.

Loading...

Loading...