Specialized Concentrated Focused

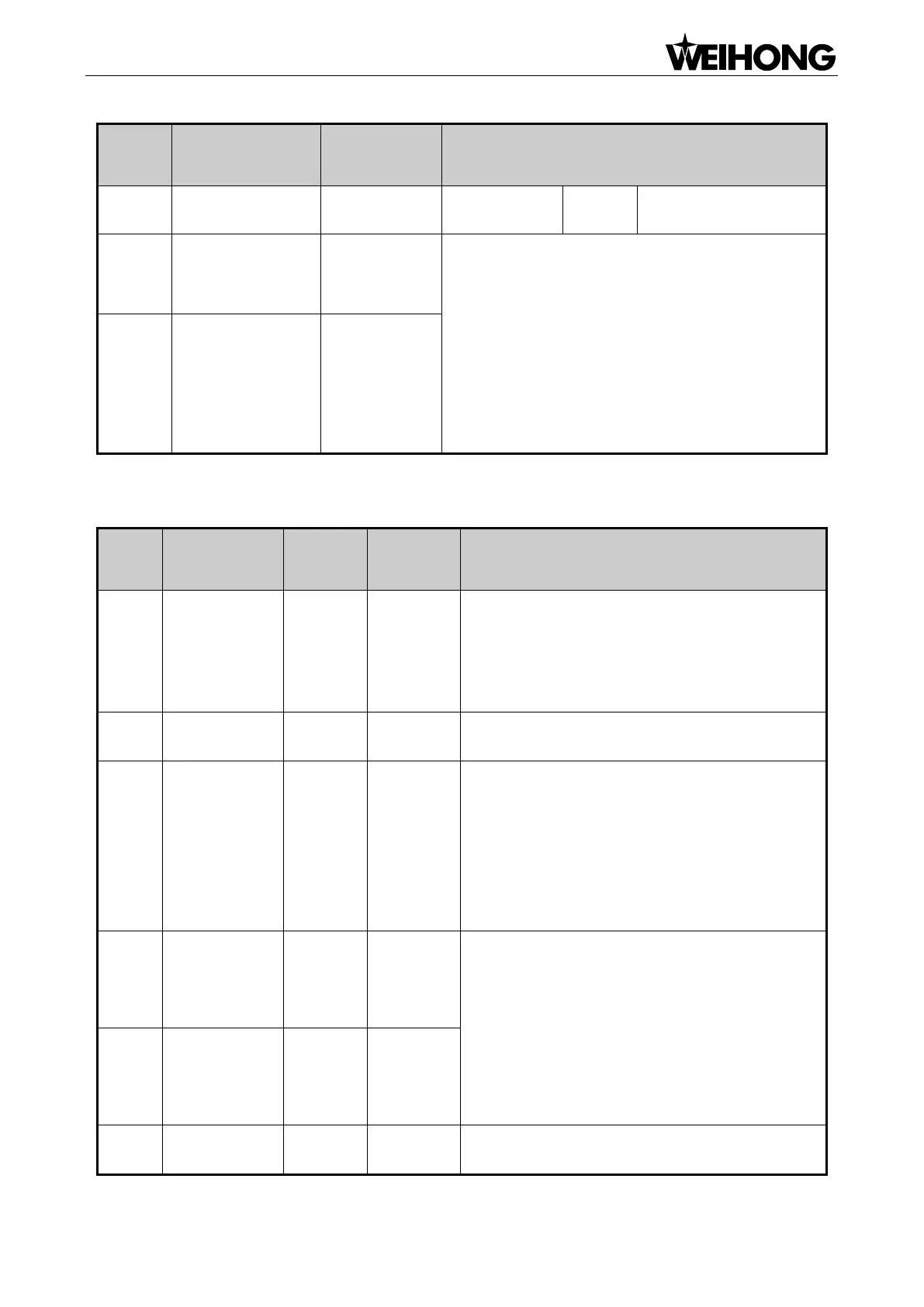

Wiring「19」

encoder after

cycle divided)

Numerator of

Electronic Gear

Ratio

Pn202 = pulse number of each encoder circle × 4 ×

mechanical deceleration ratio

Pn203 = (screw pitch / pulse equivalent)

Typical value: pitch 5mm, encoder 17-bit,

deceleration ratio 1:1, pulse equivalent 0.001mm,

Pn202=16384; Pn203=625.

pitch 5mm, encoder 17-bit, deceleration ratio 1:1,

pulse equivalent 0.0005mm, Pn202=8192; Pn203

=625

Denominator of

Electronic Gear

Ratio

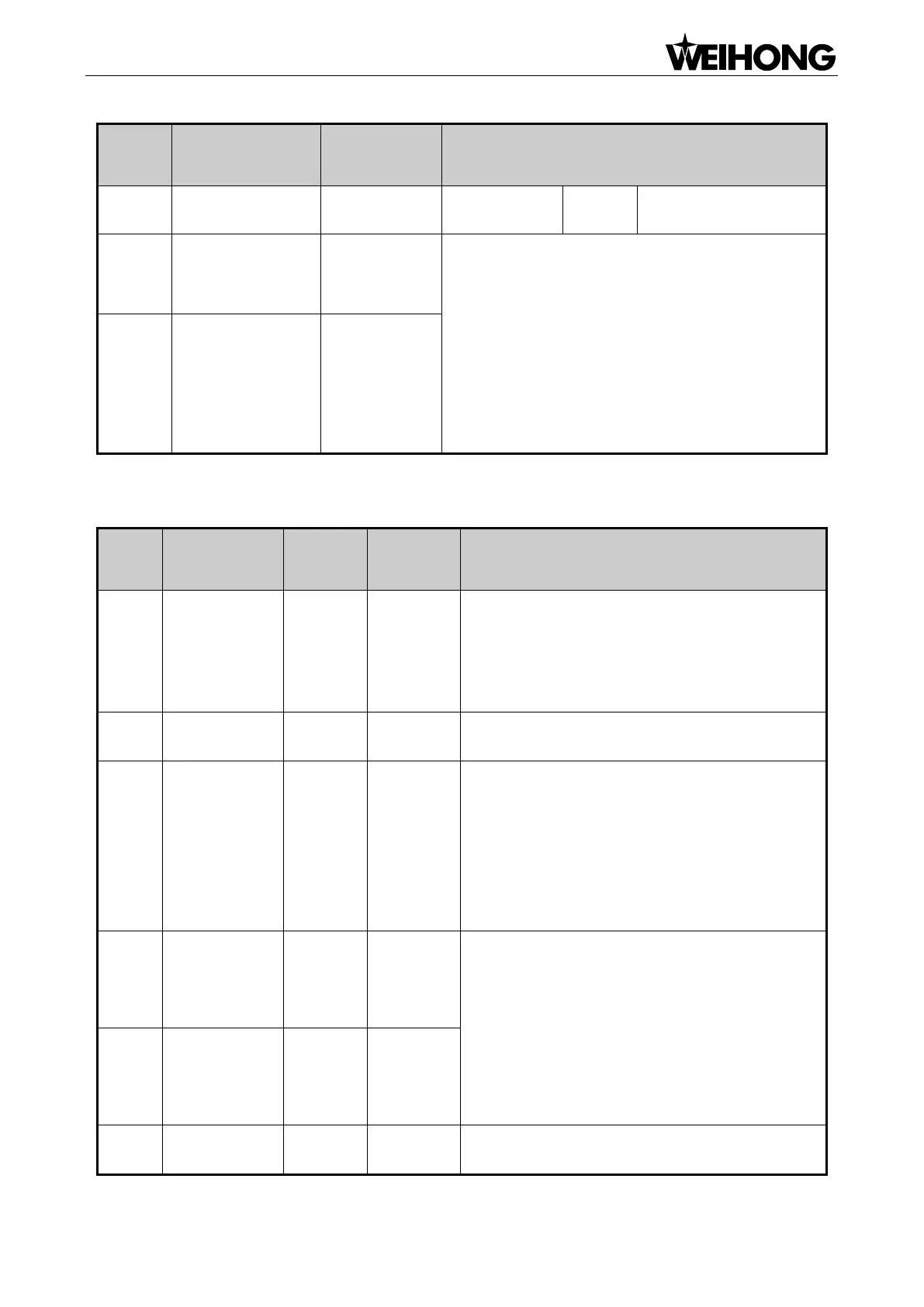

3.6.3 Parameter Setting of DELTA ASDA_ A Servo Driver

Monitor if the number of sent and received pulse

is correct by setting this parameter. In Weihong

control system, the correct quantity of pulse sent

by control card is detected by pulse inspection to

determine if there is electrical interference.

External pulse

input type

X=2: pulse + direction;

Z=1: negative logic

Z=0: when switching control mode, DIO is

maintaining the set value. Since switching

control mode is not used, Z=0

Y=0: forward rotation (anticlockwise) (from the

point of load);

Y=1: the rotation direction is reversed.

X1X0=00: position control mode

Numerator of

Electronic

Gear Ratio,

(N1)

N1 / M= encoder pulses× 4× pulse equivalent×

mechanical deceleration ratio / pitch.

Representative value: encoder pulses 2500,

pulse equivalent 0.001, pitch 5mm, mechanical

deceleration ratio 1, calculation as below:

N1 / M= 2500×4×0.001/5 = 2 / 1, N1=2, M=1;

When the multi-electronic gear ratio is not used,

P2-60~ P2-62 are not required.

Denominator

of Electronic

Gear Ratio,

(M)

0: Servo ON must be triggered by numerical

input signal.

Loading...

Loading...