With separately available guide bars, the rack guide can be converted to the following rack sizes and wall

distances:

Distance between the wall and rear of the rack guide

14 Water connection

The water-related safety should be as per DIN EN 61770. The machine can be connected to an inlet water supply without an intermedi-

ate connection to other safety equipment.

The machine and any other relevant additional devices must be connected by an authorised specialist company in

relation to local standards and regulations.

14.1 Requirements for the on-site inlet water connection

The inlet water must in microbiological aspects have the quality of drinking water

max. 60 °C (80 °C on demand)

max. 50 °C for "effect" version glass washers

3 °dH (3.8 °e / 5.34 °TH / 0.54 mmol/l ) (recommendation to prevent scaling of the machine)

30 °dH (37.6 °e / 53.4 °TH / 5.35 mmol/l) for machines with an integral softener

14.2 Requirements for the on-site water stop cock

easily accessible

not behind the machine

3/4" connector

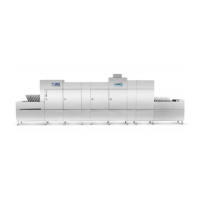

14.3 Connecting the supply hose

The supply hose may not be shortened or

damaged.

Old existing hoses may not be re-used.

Do not bend the supply hose while laying it.

The supply hose and dirt trap are located in the machine.

INFO The dirt trap prevents particles from the water supply

line entering the machine thus preventing extraneous

rust on the cutlery and in the machine.

Right view

Connect the supply hose (TWw) to the machine.

Connect the dirt trap to the on-site water stop cock.

Connect the supply hose to the dirt trap.

Open the water stop cock and test whether the connections

are tight.

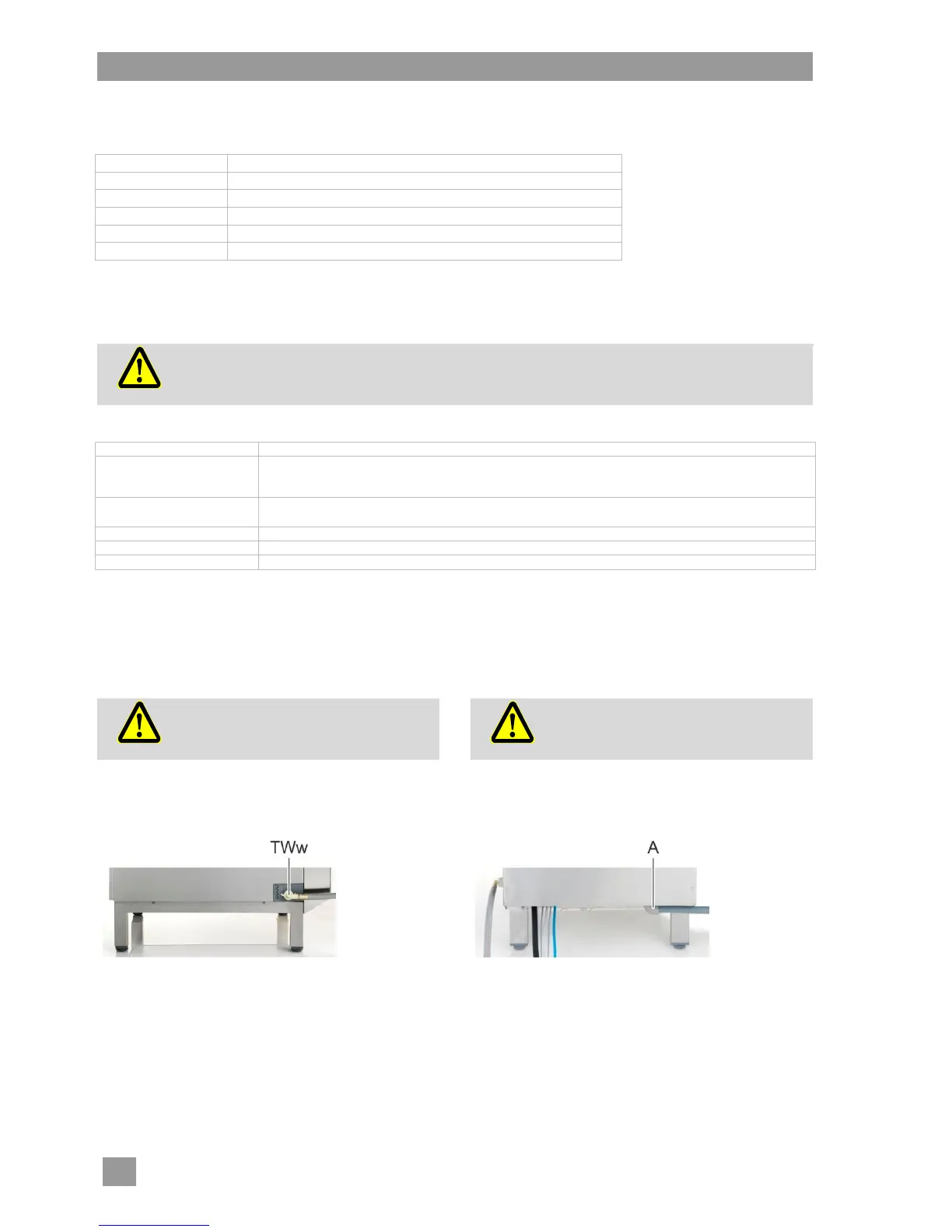

14.4 Connecting the drain hose

The drain hose may not be shortened or dam-

aged.

Do not bend the drain hose when laying it.

The drain hose is located in the machine.

INFO The machine is equipped with a drain pump. The on-

site water drain must have a trap. The maximum height

of the on-site water drain is 650 mm.

Back view

Connect the drain hose (A) to the machine.

Connect the drain hose to the on-site water drain.

Loading...

Loading...