Do you have a question about the Xinje VB5 and is the answer not in the manual?

| Model | VB5 |

|---|---|

| Category | Inverter |

| Output Power (DC Input) | 500W |

| Efficiency | 85% |

| Output Voltage (DC Input) | 220V AC |

| Protection Features | Overload, short circuit, over temperature, low voltage |

| Operating Temperature | -10℃~50℃ |

Provides a general introduction to the VB3/VB5/V5 series inverter's features.

Details electrical and performance specifications for different inverter models.

Describes the external design and layout of the inverter units.

Provides physical dimensions and mounting details for various inverter models.

Specifies environmental conditions and mounting requirements for inverter installation.

Covers general wiring precautions and procedures for power and control circuits.

Explains main circuit terminal assignments and their corresponding product types.

Illustrates a typical wiring diagram for basic inverter operation.

Details the control circuit terminals, jumpers, and their functions.

Offers guidance on mounting to comply with EMC standards and reduce noise.

Explains how to start, stop, and control the inverter using various command channels.

Describes the operation panel layout, keys, LEDs, and display functions.

Guides the user through the initial power-on procedure and checks.

Introduces parameter groups and the meaning of parameter change symbols.

Details parameters for basic inverter operation and control.

Covers parameters related to frequency setting and analog input channels.

Covers parameters related to motor starting modes, frequencies, and braking.

Explains parameters for auxiliary functions like jog, multi-speed, and energy saving.

Defines the functions assignable to the inverter's input and output terminals.

Details parameters for various motor and inverter protection functions.

Describes parameters for recording and displaying fault information.

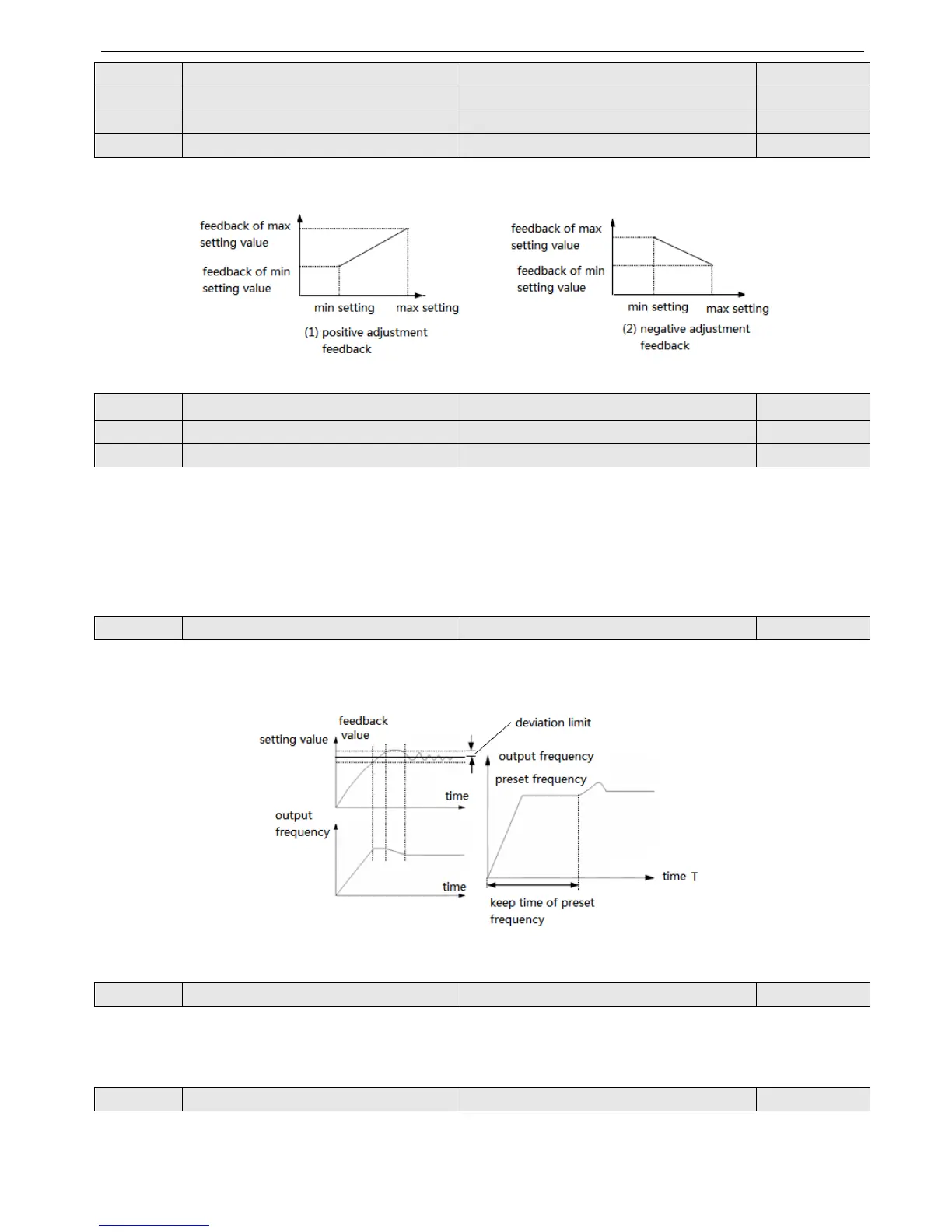

Explains parameters for setting up and tuning the closed-loop control system.

Covers parameters for the inverter's integrated simple PLC functionality.

Details parameters for configuring swing frequency operations, used in textile/fiber industries.

Explains parameters specific to vector control motor operation.

Covers parameters for special application modes like fan/pump control.

Parameters for managing default settings and user password protection.

Lists common fault codes, possible reasons, and suggested solutions for troubleshooting.

Explains how to access and use recorded fault codes and parameters to diagnose issues.

Provides methods for resetting the inverter after a fault occurs.

Outlines routine checks and general maintenance practices for the inverter.

Details specific inspection points and countermeasures for periodic maintenance.

Explains the warranty terms and conditions for the Xinje inverter.

Introduces the RS485 communication port and Modbus-RTU protocol support.

Covers networking modes and communication protocol details for connecting devices.

Describes the character structure, information, and parameters for Modbus-RTU communication.

Provides information on selecting and wiring brake resistors for inverters.

Lists compatible operate panel models and their mounting dimensions.

Details available extension cable types and lengths for the operate panel.