VESDA by Xtralis VESDAVLSProduct Guide

www.xtralis.com 3

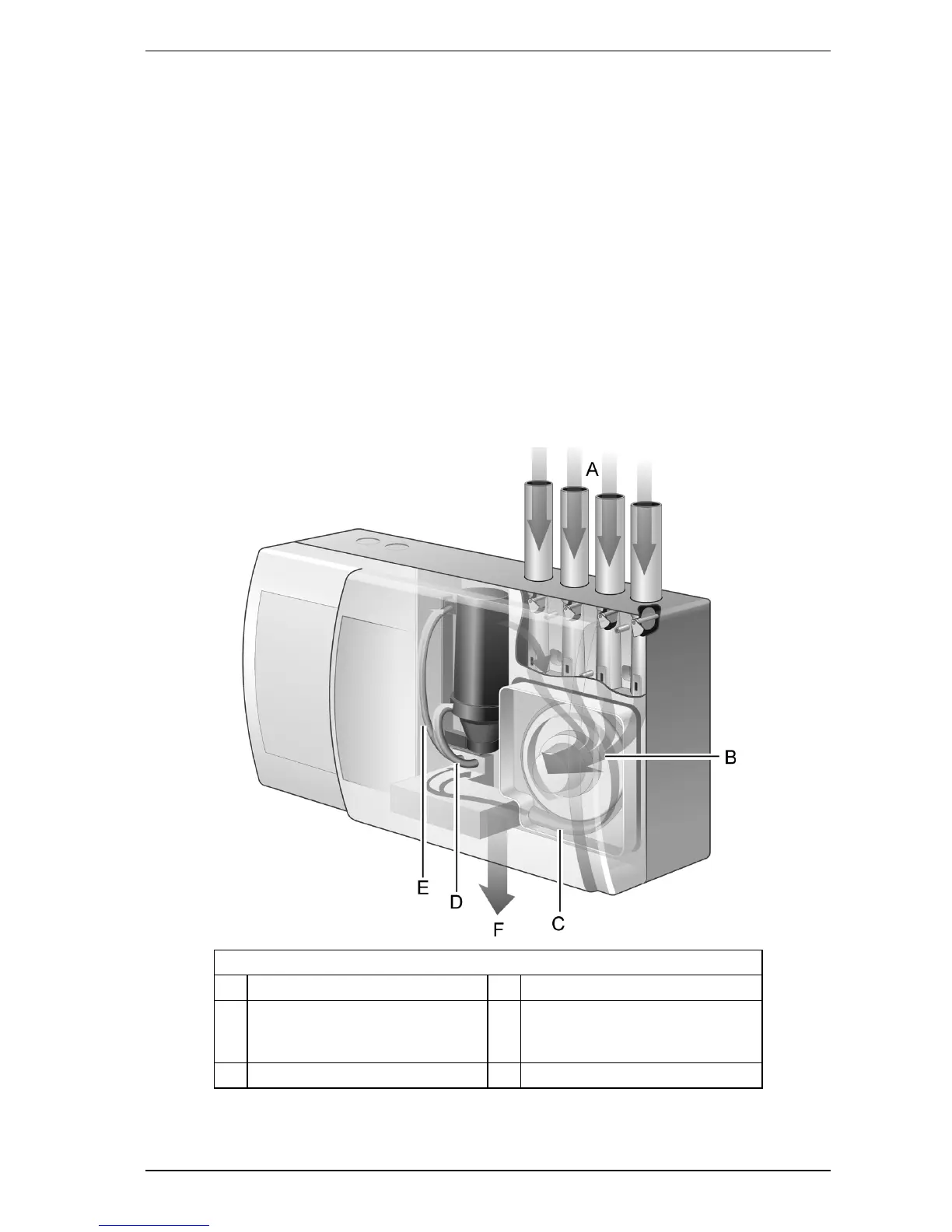

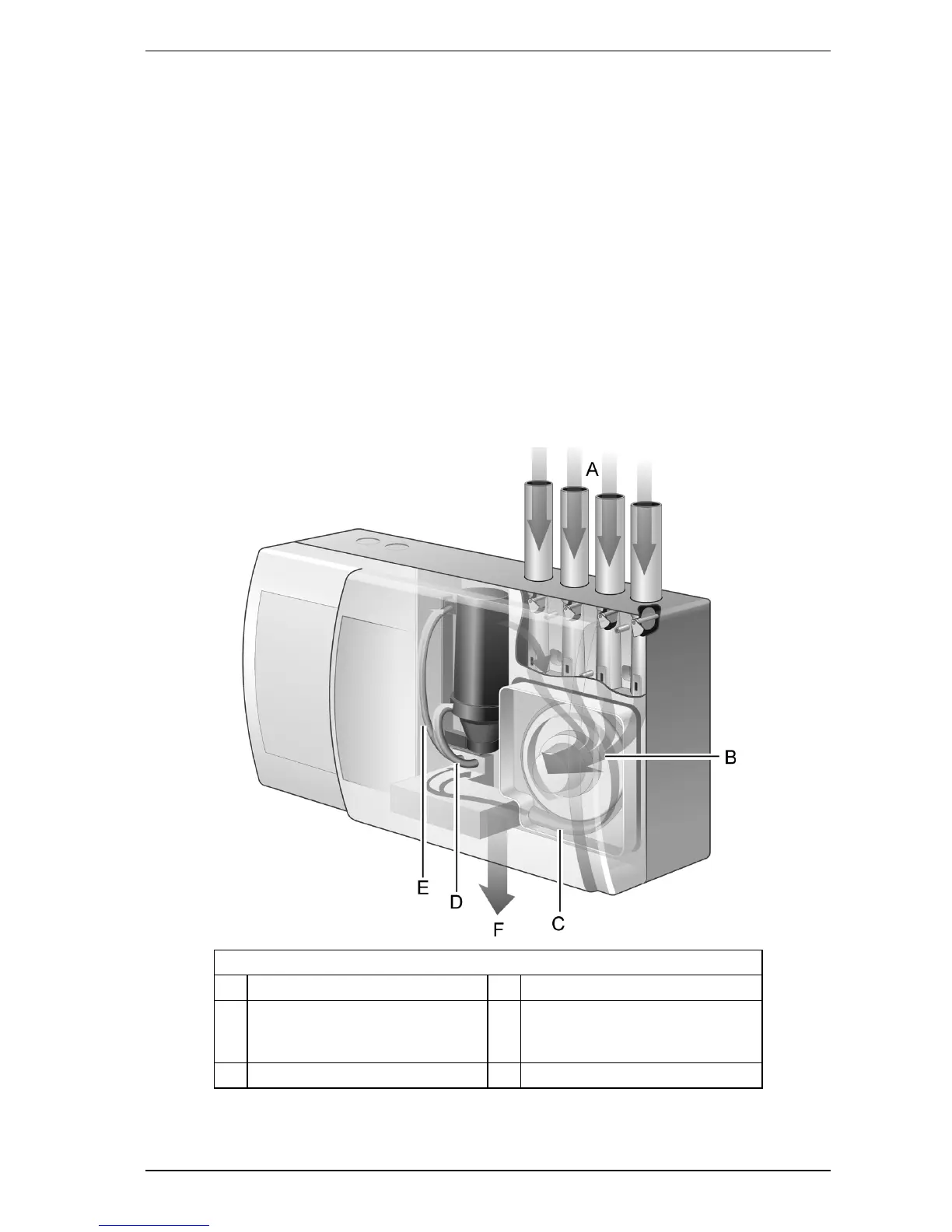

2 Operation

An air sampling pipe network with sampling holes at appropriate spacing collects air samples from a protected

area.

An integrated Aspirator draws air in the sampling pipes through a Pipe Inlet Manifold (up to four pipes can be

connected to a VESDA VLS detector). For further information on air sampling pipe network, refer to the Pipe

Network Design and Installation Manuals.

Each pipe inlet in the manifold has a valve that can open or close the flow of air to the pipe. The scan function

controls the opening and closing of the valves to detect the smoke carrying pipe. Refer to Section 2.1 on page

4 for further information.

Some of the sampled air flows to the dual stage air filter. The first stage filtration removes dust and dirt from

the sampled air and a small percentage of this air then flows to the laser detector chamber for detection

smoke.

Any smoke detected in the laser detection chamber is signaled to the main processor card. If the presence of

detected smoke is higher than the set thresholds it will be reported as an alert, action, fire 1 or fire 2 Alarm

depending upon the set alarm thresholds. The second stage filtration further filters the air to make it ultra clean

air. The ultra clean air is used to protect the optical surfaces in the laser detector chamber.

Legend

A Air inlets from pipe networks D -flows into the chamber for testing

B Air is drawn into the aspirator E -is filtered a second time, then used

to flush the chamber with ultra clean

air

C Some air is filtered and: F All air is then exhausted

Figure 2-1: Operation and internal air flow of a VESDA VLS

Loading...

Loading...