11

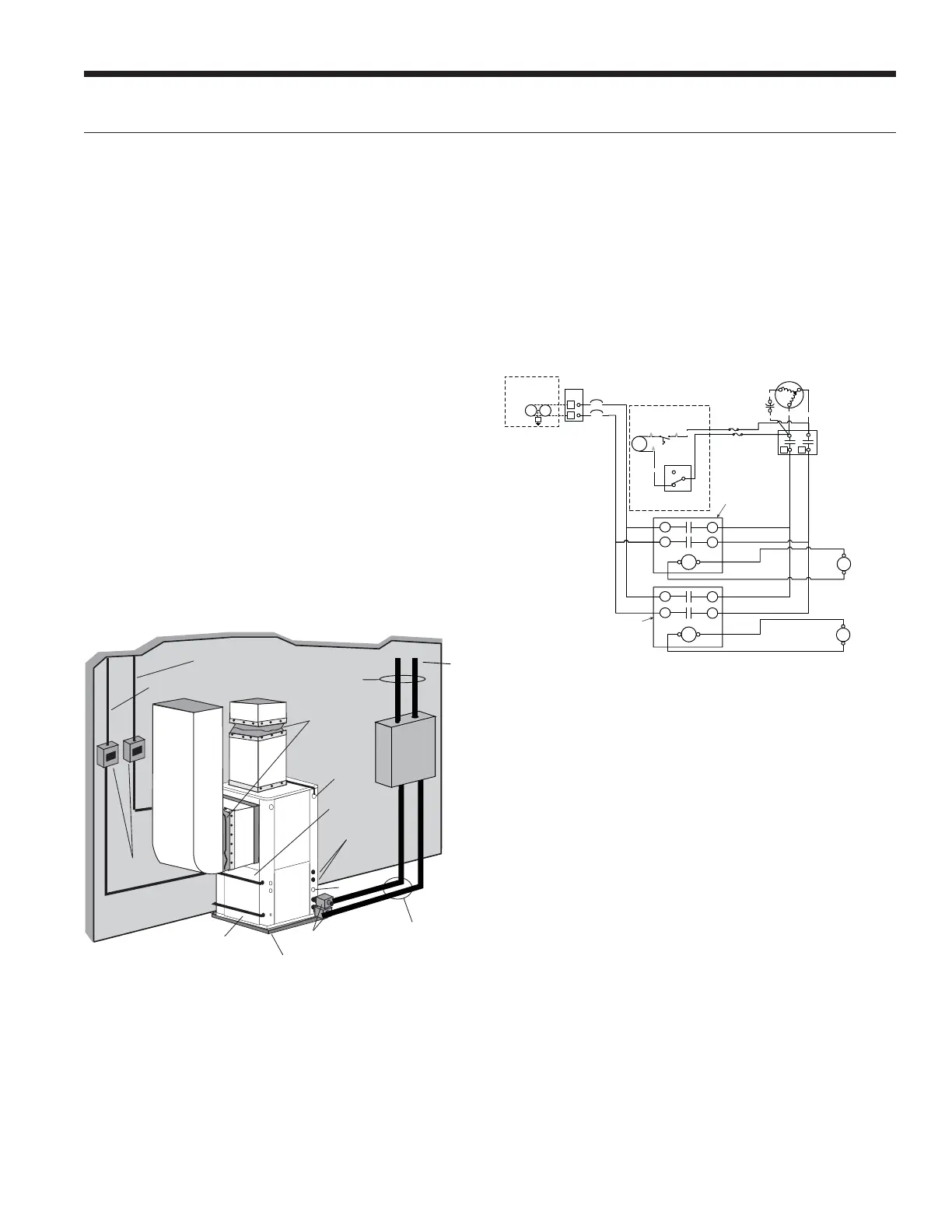

Figure 7: Closed Loop Ground Source Application

Once piping is completed between the unit, pumps and

the ground loop, final purging and charging of the loop

is required. A flush cart (or a 1.5 HP pump minimum) is

needed to achieve adequate flow velocity in the loop to

purge air and dirt particles from the loop itself. A filter

MUST be used when flushing a loop. The standard 100

micron filter bag (LFC-F100M) is acceptable for capturing

relatively large debris such as pipe shavings, gravel, and

medium sand particles. In certain installation locations

other smaller materials such as fine sand, silt, and clay

can be less than 75 microns. For these smaller particles

the use of the 1 micron filter bag is required (LFC-F1M).

It is also recommended to run the flush cart with the

1 micron filter bag for at least 30 minutes. Antifreeze

solution is used in most areas to prevent freezing. Flush

the system adequately to remove as much air as possible

then pressurize the loop to a static pressure of 40-50 psi

(summer) or 50-75 psi (winter). This is normally adequate

for good system operation. Loop static pressure will

fluctuate with the seasons. Pressures will be higher in

the winter months than during the cooling season. This

fluctuation is normal and should be considered when

initially charging the system.

Flexible Duct

Collar

Vibration Absorbing Pad

P/T Plugs

Drain

Hot Water Generator

Connections

Auxiliary

Heater

Knockout

Low

Voltage to

Thermostat

Unit Supply

Auxiliary Heat

Supply

Insulated piping

or hose kit

Disconnects

(If Applicable)

Unit Power

P/T

TO

LOOP

GeoLink

®

Flow

C

enter

GeoLink

®

Polyethylene w/

Armaflex

®

Insulation

NOTE: Additional information can be found in Flow Center

installation manual and Flush Cart manual.

Closed Loop Ground Source Systems

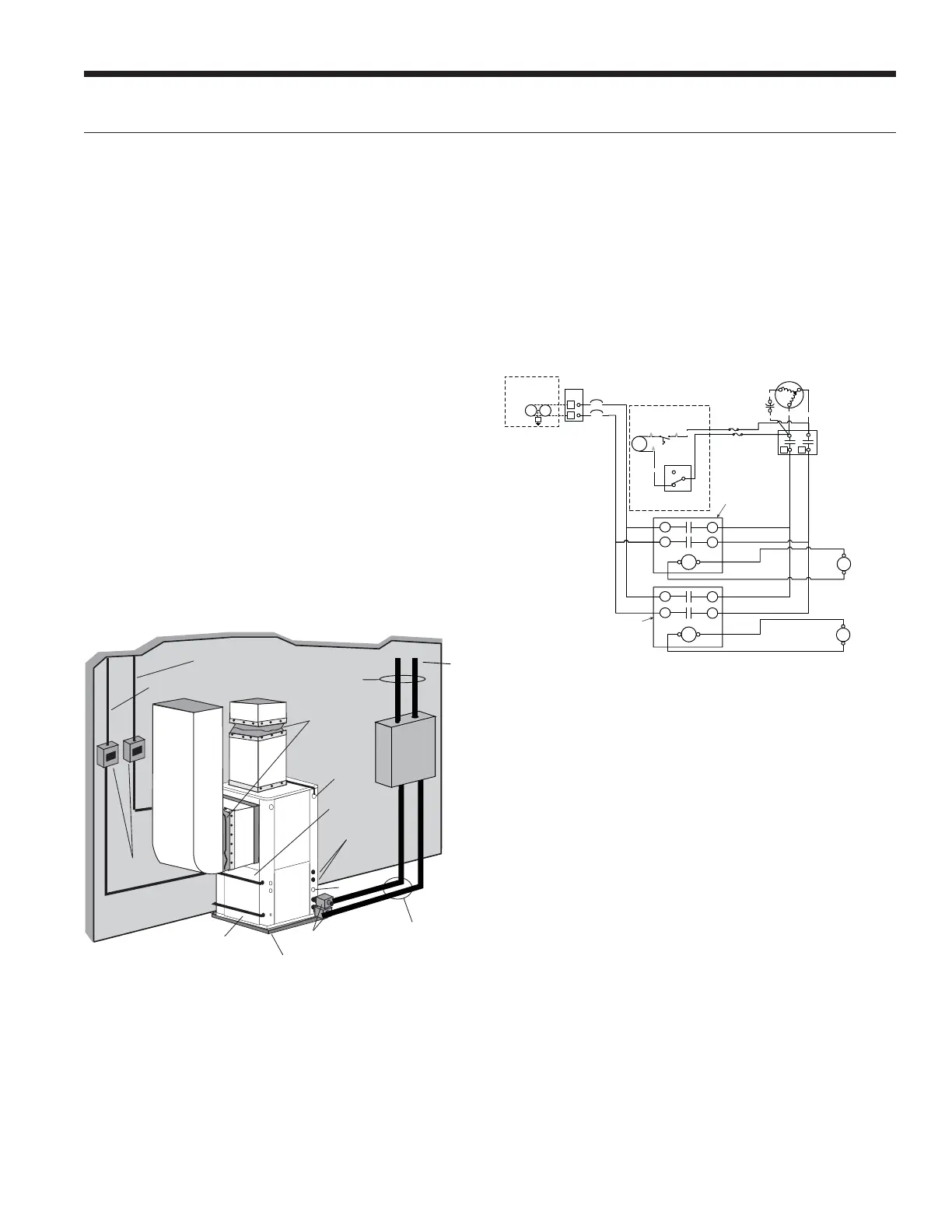

Figure 8: Primary/Secondary Wiring with Aurora Base Control

(no AXB Board)

CC

T2

T1

Compressor

C

R

S

Blue

L1

L2

Black

Red

Ta n (6 )

Cap

Ext Pump

1/2 hp Total

208-230/60/1

Pump

G

1

2

PB1

1

2

Pump

Circuit

Breaker

Circuit

Breaker

1

5A

5A

Optional Internal

HWG Pump

HWG

Pump

Purple

Hot Water

Limit Switch

130°F

Blue

1

2

3

Cabinet

HW Switch

Field Supplied

Relay for Heat

Pump 1

Field Supplied

Relay for Heat

Pump 2

Heat Pump 1

Contactor Coil

Heat Pump 2

Contactor Coil

Field Supplied

Fuses 5A

Multiple Units on One Flow Center

When two heat pumps are connected to one loop pumping system,

follow figure 8. Installer will be required to supply fuses, two relays,

and wiring. It is recommended that water solenoid valves

be installed on heat pumps that share a flow center. This is

to allow water flow through only the heat pump that has

a demand. Circulating fluid through a heat exchanger of a

system that is not operating could be detrimental to the

long-term reliability of the compressor.

LX SERIES INSTALLATION MANUAL

Loading...

Loading...