505428-YTG-V-0417

4 Johnson Controls Unitary Products

Condensing Unit Features and Benefits

Features

• Meets or exceeds ASHRAE 90.1 standards.

• Scroll compressors provide both high efficiency and

reliability.

• Smart Equipment™ Controls

• Dual refrigerant circuits on PD and YD models.

• Condensing unit coils are constructed of reliable and

durable Micro-Channel aluminum tube and fins for long

lasting, efficient operation. Micro-Channel technology

provides exceptional durability along with reduced

product weight and less refrigerant charge. Heat pumps

units are equipped with aluminum fin, copper tube coils

providing durability, reliability and value.

• Crankcase heaters that de-energize when compressors

are operating.

• Both high and low pressure controls. Since these

controls are self-contained, there are no capillary lines

to be damaged.

• Internal compressor motor protection.

• Class 2, 24-volt thermostat control circuit protected by a

re-settable breaker.

• Standard factory installed service valves.

• Filter-driers are shipped in the unit's control box for field

installation in the liquid line leaving the outdoor unit.

• Copper stub-outs are factory mounted on the suction

and liquid lines to simplify the field piping connections.

• Smart Equipment™ Controls provide stable cooling

operation at ambient temperatures down to 40°F with

low ambient kits available for operation to 0°F.

• Capacity staging for more economical operation and

stable temperature levels within the conditioned space.

• Smart Equipment™ Controls control board uses a three

times, you're out philosophy. The high, low-pressure

switch, anti-freeze protection, low voltage or heating

high limit must trip three times within two hours before

the unit control board will lock out the associated

compressor. An alarm message will be displayed on the

LCD screen

• Smart Equipment™ Controls monitor each safety

independently (High pressure, low pressure, low

voltage) allowing ease of troubleshooting if any

problems arise.

• Inherently protected condenser fan motors.

• Technicoat or E-coat coated outdoor coils for sea coast

or corrosive environment applications.

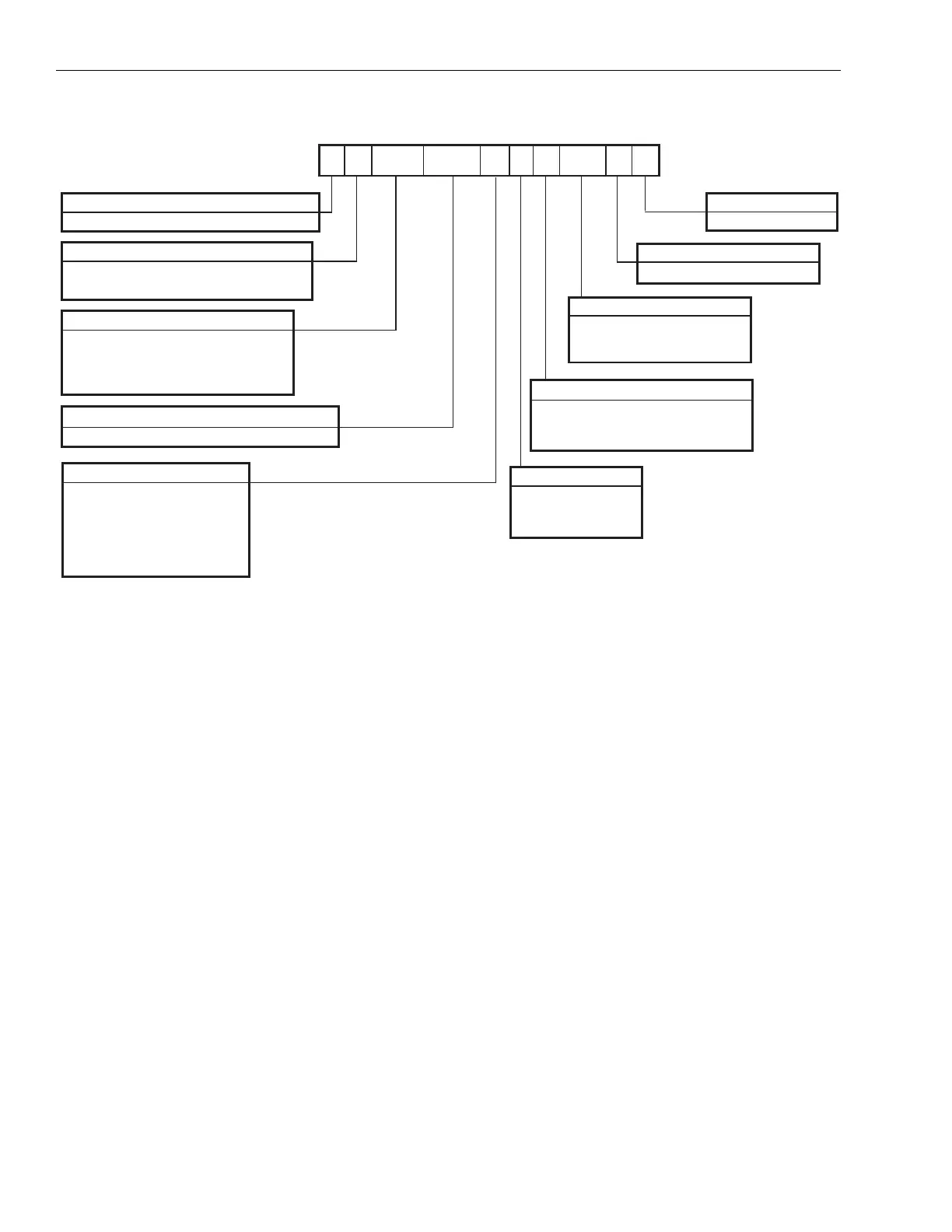

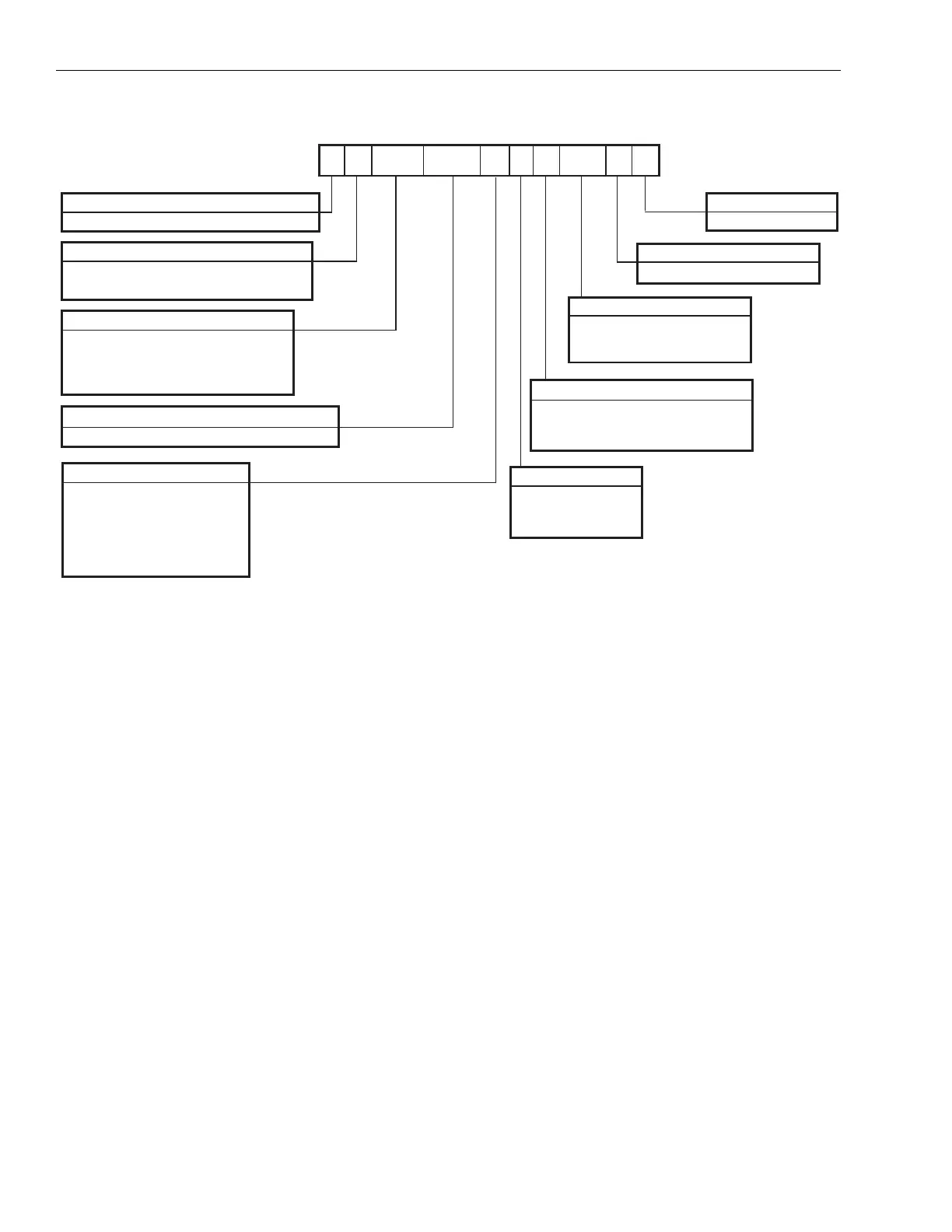

Product Category

N = Split System, Air Handler, AC & HP R-410A

Product Identifier

Nominal Cooling Capacity - MBH

090 = 7-1/2 Ton

120 = 10 Ton

180 = 15 Ton

240 = 20 Ton

C00 = Cooling Only

Product Options

AA = No Options Installed

EJ = E-Coat Evaporator Coil

TJ = Technicoat Evaporator Coil

Installation Options

1

B = IntelliSpeed VFD

C = IntelliSpeed VFD w/Bypass

D = Customer Installed IntelliSpeed VFD

2 = 208/230-3-60

4 = 460-3-60

5 = 575-3-60

Configured Split Air Handler Model Number Nomenclature

B = 1.5 HP Motor

C = 2.0 HP Motor

D = 3.0 HP Motor

E = 5.0 HP Motor

F = 7.5 HP Motor

N = None (Motor Drive Kit Reg)

Airflow

Product Generation

1 = First Generation

Voltage

Heat Type & Nominal Heat Capacity

N

L

240

C00 B

6

A

AA

1

A

Product Style

A = Style A

1. In order for the IntelliSpeed option to function

properly some field programming will be required.

See unit installation manual for details.

L = Standard Efficiency, 2-pipe w/Intellispeed

M = Standard Efficiency, 4-pipe w/Intellispeed

Loading...

Loading...