JOHNSON CONTROLS

123

FORM 160.84-OM1

ISSUE DATE: 9/21/2017

5

SECTION 5 - MAINTENANCE

PREVENTATIVE MAINTENANCE

It is the responsibility of the owner to provide the nec-

essary daily, monthly and yearly maintenance require-

ments of the system.

In any operating system it is most important to pro-

vide a planned maintenance and inspection of its func-

tioning parts to keep it operating at its peak efficiency.

Therefore, the following maintenance should be per-

formed when prescribed.

IMPORTANT – If a unit failure occurs

due to improper maintenance during the

warranty period; Johnson Controls will

not be liable for costs incurred to return

the system to satisfactory operation.

Electrical Isolation

1. Isolate electrical power supply to the chiller from

the facility

2. Isolate the Power Panel battery from the Uninter-

rupted Power Supply by opening the Power Panel

disconnect switch.

3. Isolateplantuidowtothechilleratappropriate

valves or have refrigerant isolated to prevent free-

wheeling the driveline and generating electrical

energy from the permanent magnet rotor.

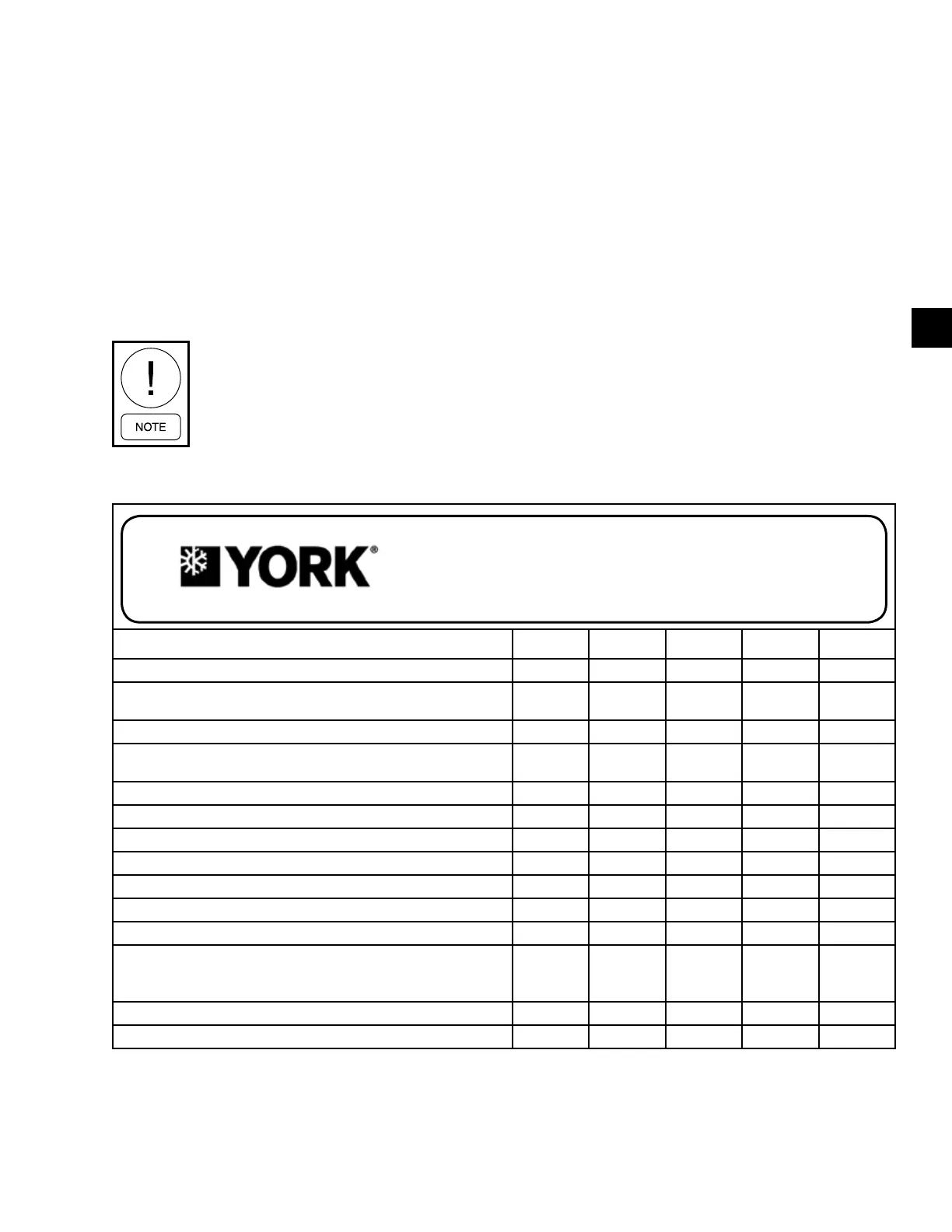

TABLE 13 - MAINTENANCE REQUIREMENTS

Procedure Daily Weekly Monthly Yearly Other

Record operating conditions (on applicable Log Form) X

Check operating parameters for indication of tube fouling or

refrigerant loss

X

Check three-phase voltage and current balance X

Check programmable operating setpoints and safety cut-outs.

Make sure they are correct for the application

X

Verify condenser and evaporator water ows X

Leak check and repair leaks as needed

1

X

Check and tighten all electrical connections X

Clean or backush VSD heat exchanger X

Replace VSD starter coolant X

Measure motor winding and insulation resistance X

Perform refrigerant analysis

1

X

Review operating data for trends which indicate increasing

vibration or power consumption. The MBC data includes 1 x

rotational speed vibration in displacement.

X

Clean tubes X

2

Perform Eddy current testing and inspect tubes 2-5 Years

For operating and maintenance requirements listed above, refer to appropriate service literature, or contact your local Johnson Controls

Service Ofce.

1

This procedure must be performed at the specied time interval by an Industry Certied Technician who has been trained and qualied

to work on this type of YORK equipment. A record of this procedure being successfully carried out must be maintained on le by the

equipment owner should proof of adequate maintenance be required at a later date for warranty validation purposes.

2

More frequent service may be required depending on local operating conditions.

MAINTENANCE REQUIREMENTS FOR YMC

2

CHILLERS

Loading...

Loading...