JOHNSON CONTROLS

91

SECTION 3 - OPTIVIEW™ CONTROL CENTER FUNCTIONS AND NAVIGATION

FORM 160.84-OM1

ISSUE DATE: 9/21/2017

3

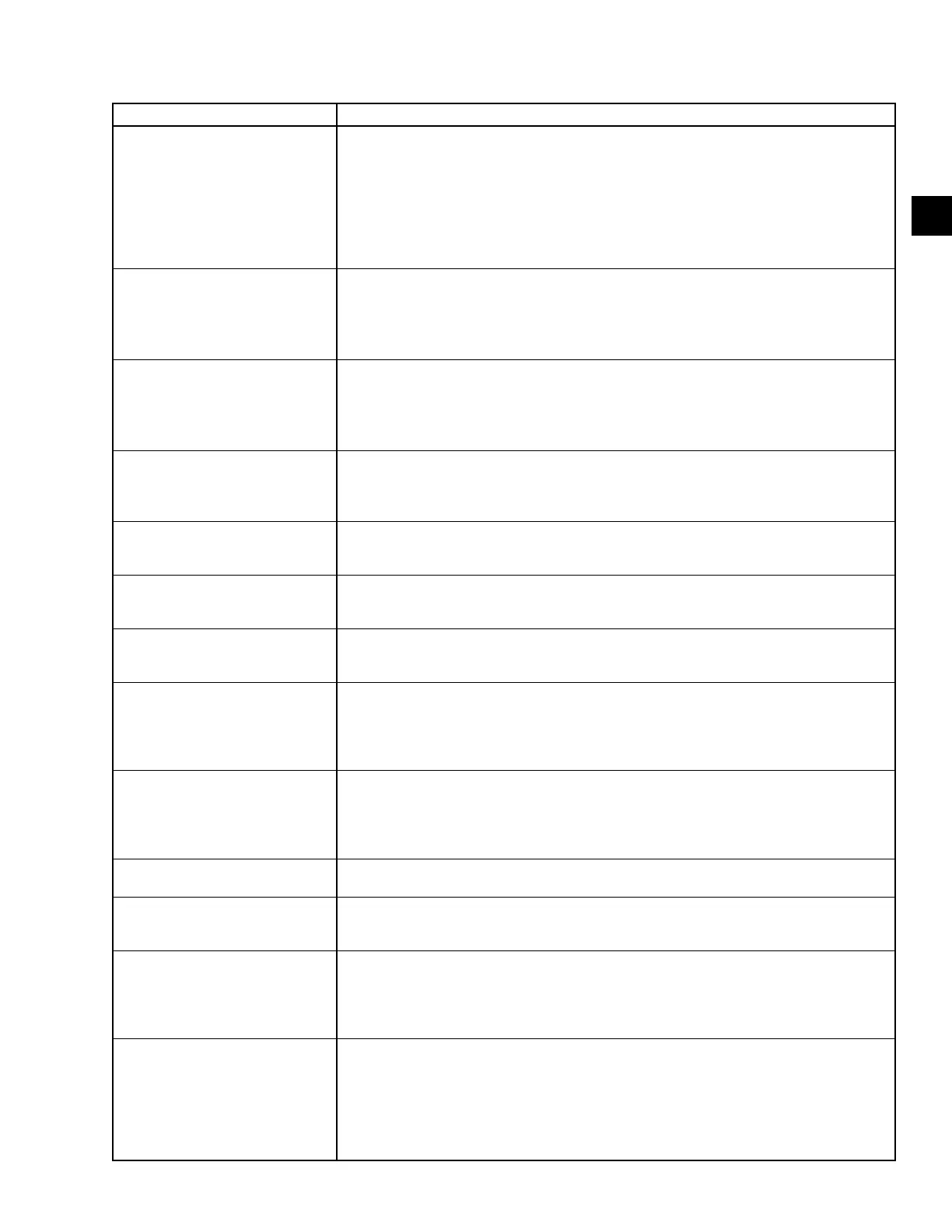

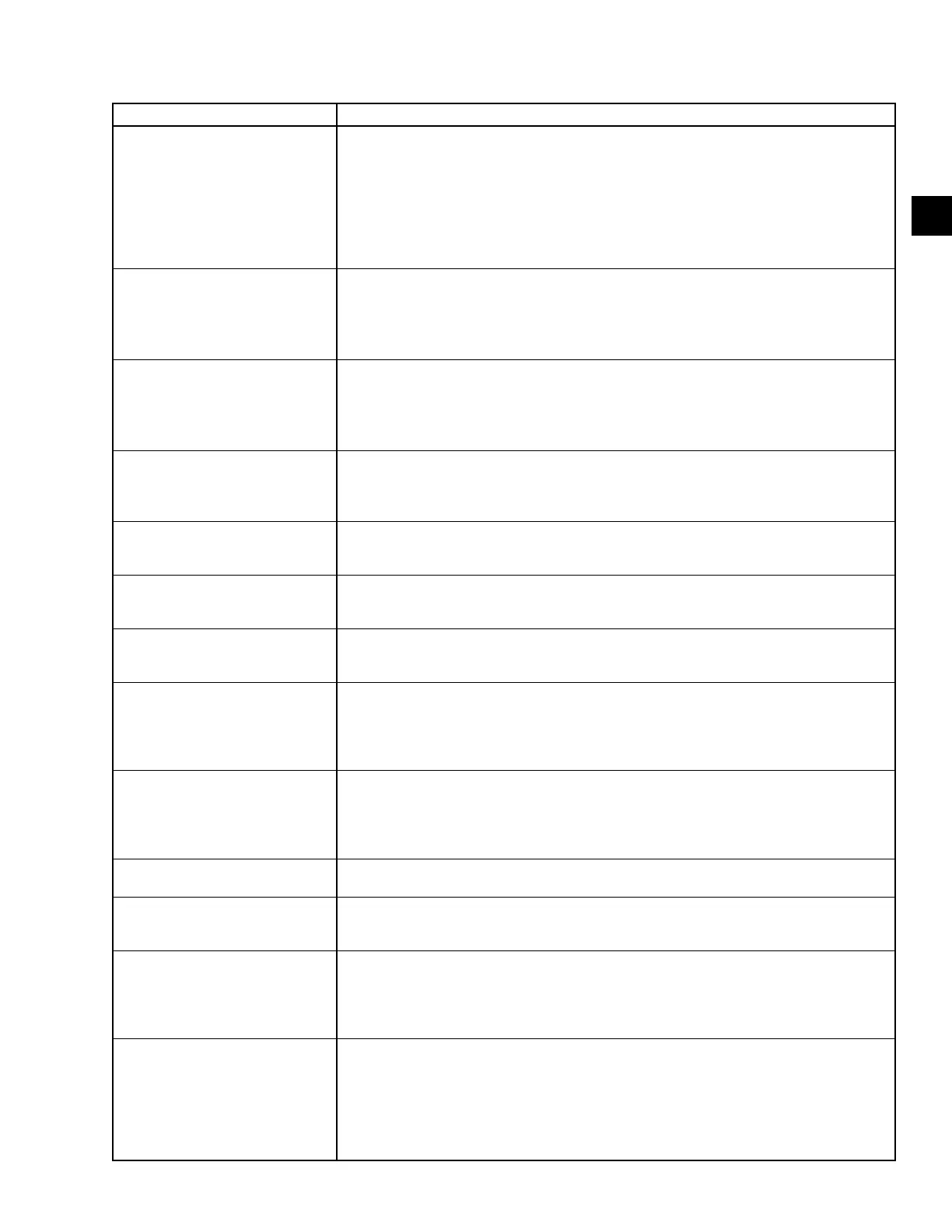

MESSAGE DESCRIPTION

WARNING - LOSS OF

SUBCOOLER LIQUID SEAL

The chiller is running greater than 30 minutes and the Subcooler Effectiveness value

decreased less than 0.400 (ADMIN programmable) at any drop leg refrigerant tempera-

ture or increased greater than 1.50 (ADMIN programmable) when the drop leg refriger-

ant temperature is at least 0.5 °F below or any amount above the Entering Condenser

Liquid Temperature. The subcooler effectiveness is (Condenser Sat Temp - Drop leg

refrigerant temp)/(Cond Sat Temp - Entering Condenser Liquid Temp). To clear mes-

sage press WARNING RESET key on HOME Screen when logged in at OPERATOR (or

higher) access level.

WARNING – MBC – HIGH AXIAL

OSCILLATOR VOLTAGE

This manual reset warning is set when the internal oscillator that drives the axial posi-

tion sensor coil is overloaded for one continuous second. This is typically the result of

an open in the connection to the shaft position sensor. It could also be a failure of the

MBC control board. This message will clear when the voltage is normal and the WARN-

ING RESET key is pressed in OPERATOR (or higher) access mode.

WARNING – MBC – HIGH

RADIAL OSCILLATOR

VOLTAGE

This manual reset warning is set when the internal oscillator that drives the radial posi-

tion sensor coil is overloaded for one continuous second. This is typically the result of

an opening in the connection to the shaft position sensor. It could also be a failure of the

MBC control board. This message will clear when the voltage is normal and the WARN-

ING RESET key is pressed in OPERATOR (or higher) access mode.

WARNING – MBC – CHECKSUM

CENTERING

This warning appears when the MBC Axial Centering process was never performed, or

not correctly realized internally. The centering process as found in the calibration section

of Form 160.84-M2 will need to be done in ADMIN access. Then this message will clear

when the WARNING RESET key is pressed in OPERATOR (or higher) access mode.

WARNING – MBC – DSP

WATCHDOG

A software reboot has occurred on the control board due to processor problem, but re-

set with the reboot. This message will clear when the WARNING RESET key is pressed

in OPERATOR (or higher) access mode.

WARNING – MBC – AMP

WATCHDOG

A software reboot has occurred on the amplier (power) board due to processor prob-

lem, but reset with the reboot. This message will clear when the WARNING RESET key

is pressed in OPERATOR (or higher) access mode.

WARNING – MBC – INTERNAL

ALARM

The MBC experienced an unsatisfactory condition detected internally to the control sys-

tem. This message will clear when the condition is resolved and the WARNING RESET

key is pressed in OPERATOR (or higher) access mode.

WARNING – MBC – ROTATION

MODE OFF

During the time the MBC Rotation Mode is commanded ON by the microboard via serial

comms this warning is set if the MBC reports Rotation Mode is OFF by serial comms.

This warning is inhibited if MBC communication is not initiated and during the rst 15

seconds after the Rotation Mode is commanded ON. This warning is released when

Rotation Mode status matches the microboard command to the MBC.

WARNING – MOTOR – HIGH

CURRENT LIMIT

The chiller motor current is greater than or equal to the Motor Overload current limit.

The Motor Overload current limit is predetermined from the motor model and Maximum

VSD Output Current. While this condition is in effect, chiller capacity control is in over-

ride to reduce current. Normal LCHLT capacity control operation is resumed and this

message automatically clears when the motor current decreases below this limit.

WARNING – MOTOR – HIGH

HOUSING TEMPERATURE

The Motor Housing Temperature is greater than or equal to 167°F (75°C). This warning

is released when Motor Housing Temperature is less than 158°F (70°C).

WARNING- MOTOR - HIGH

ROTOR TEMPERATURE

This warning occurs when the estimated rotor temperatures exceeds 230°F (110°C) for

3 continuous seconds. This warning will automatically clear when all winding tempera-

tures decrease below the warning threshold

WARNING - MOTOR – HIGH

WINDING TEMPERATURE

This warning occurs when any of the enabled motor winding temperatures exceeds

275°F (135°C) for 3 continuous seconds. This warning will automatically clear when all

winding temperatures decrease below the warning threshold. Also it will not act on any

individual winding temperature sensor that has been disabled with the TEMPERATURE

DISABLED Setpoint on the Motor Details Screen.

WARNING – REAL TIME

CLOCK FAILURE

During the initialization process that occurs when power is applied to the control center,

test data is written to a location in the BRAM battery backed memory device (IC loca-

tion U52 on Microboard). This data is then read from the BRAM and compared to the

test data. If the read data is not the same as that which was written to the device, it is

assumed the BRAM and Real time Clock operation is defective and this message is dis-

played. The BRAM should be replaced by a qualied Service Technician. This message

automatically clears when the BRAM problem has been solved.

TABLE 9 - WARNING MESSAGES

Loading...

Loading...