Page - 26/100 AE0ZP0EC - AC-0 SSL SENSORED - User Manual

programming (if used).

C8 FLASH Must be connected to C7 for the Flash memory

programming (if used).

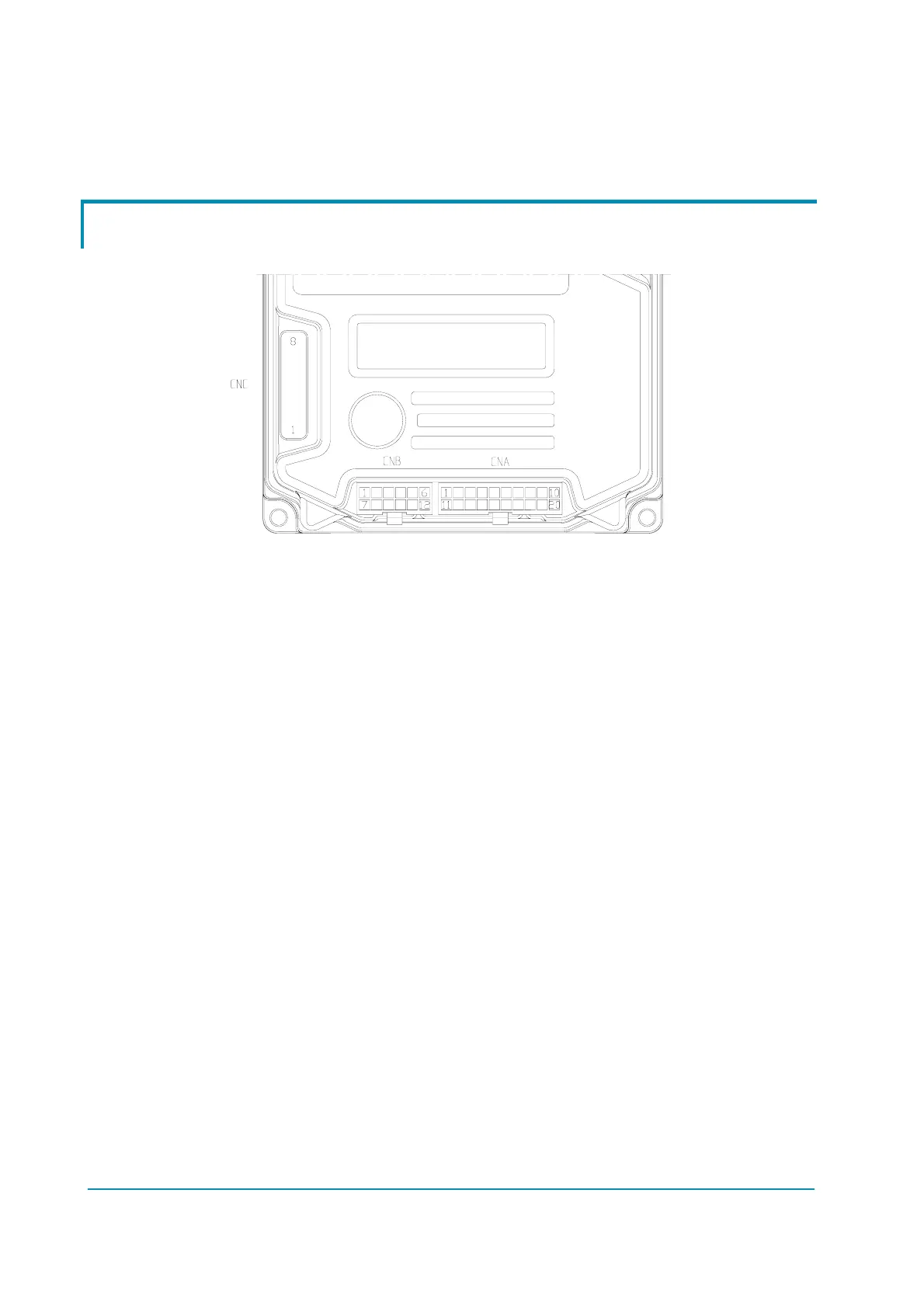

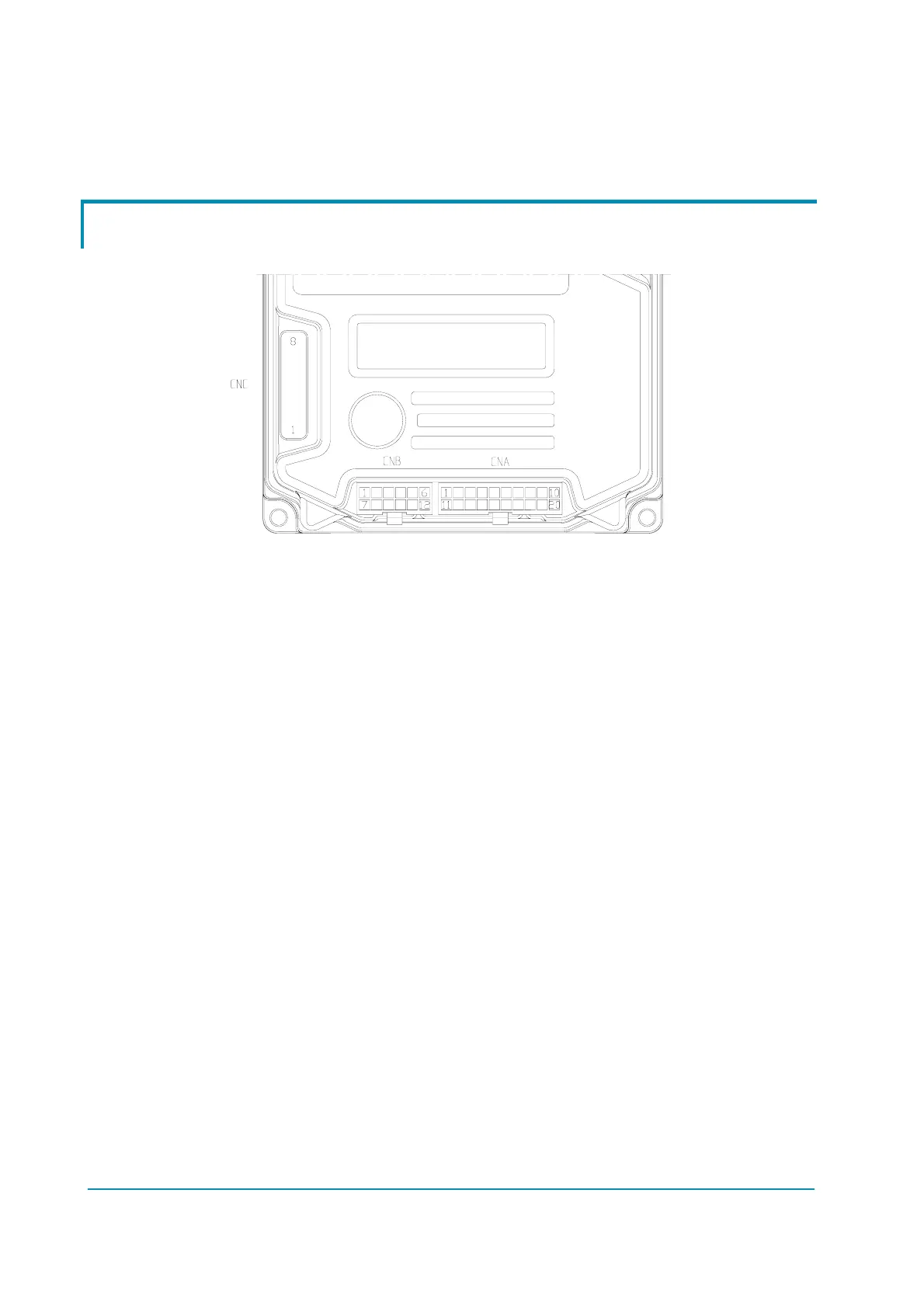

6.2 Connectors of the logic – Pump configuration

Figure 6–4

CNA connector

A1 NMC Negative of main contactor coil.

A2 PMC/PEB Positive of main contactor coil and of the first auxiliary

output.

A3 NAUX 1 Negative of the first auxiliary output.

A4 NAUX 2 Negative of the second auxiliary output.

A5 PPC/PEV Positive of the second and the third auxiliary output.

A6 NAUX 3 Negative of the third auxiliary output.

A7 CAN LOW Low level CAN-BUS voltage I/O.

A8 -BATT -Batt.

A9 ENC + Encoder Positive Supply (+5 or +12 Vdc).

A10 ENC - Encoder Negative Supply (GND to minus battery).

A11 HM (+B) This output provides a +Batt for general-purpose

applications; 3 A maximum current.

A12 -BATT -Batt.

A13 MOT TH Motor thermal sensor input. The internal pull-up is a

fixed 2 mA (Max 5 V) source current.

A14 SPEED 3 Input for third speed request; it is active high.

A15 SPEED 2 Input for second speed request; it is active high.

A16 +12V This output provides a +12 V signal for the MDI PRC;

100 mA maximum current.

A17 CAN HIGH High level CAN-BUS voltage I/O.

A18 CPOTB Proportional electrovalves potentiometer wiper.

A19 ENC A Encoder Channel A.

Loading...

Loading...