Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 79

Features Common to Compact 5000 I/O Digital Modules Chapter 2

Synchronized Sampling lets you configure a test stand, for example, and take

many measurements simultaneously across many modules, if needed, while still

precisely coordinating the sampling. With these modules, the synchronized

sampling coordinates within approximately ± 10 μs.

Table 12 describes how you can use time stamps.

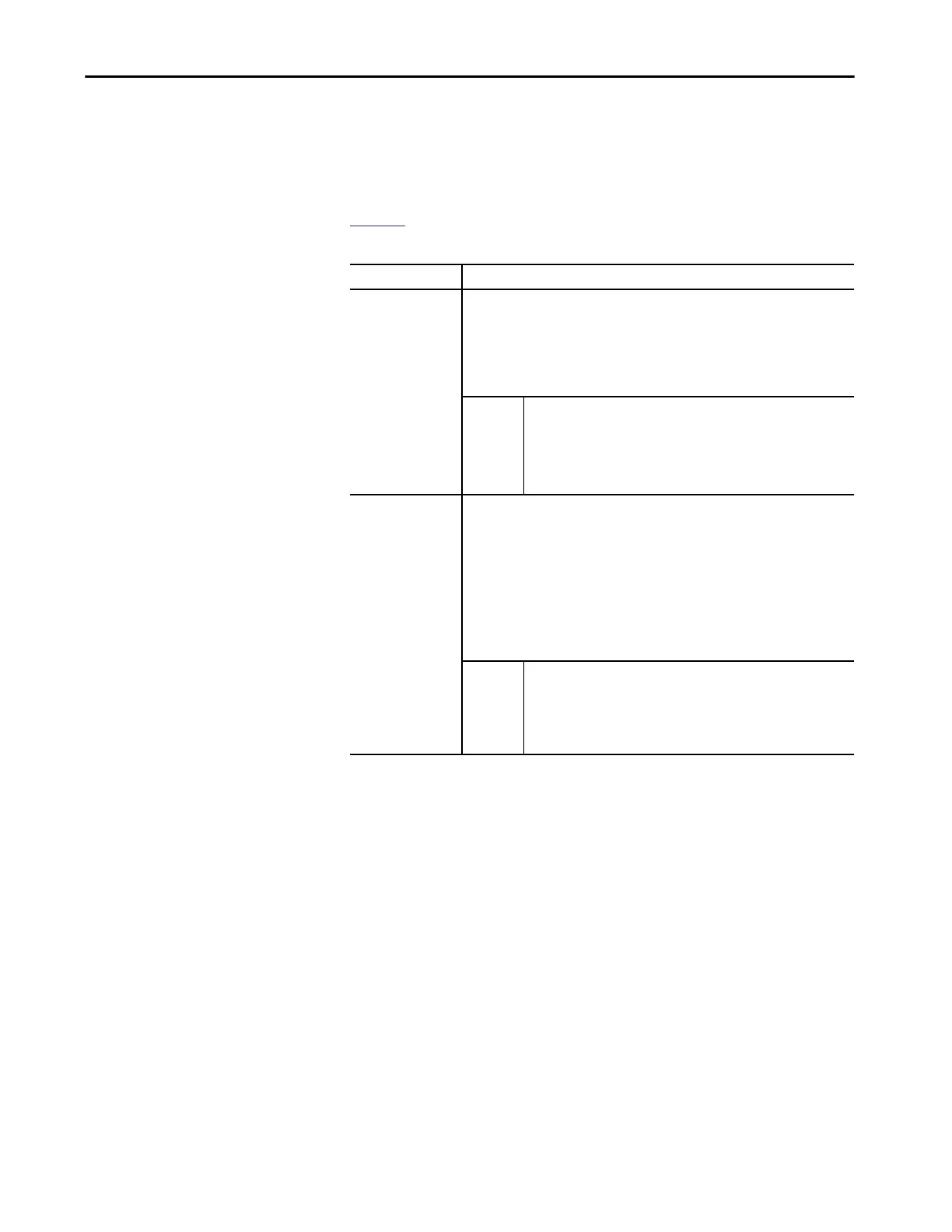

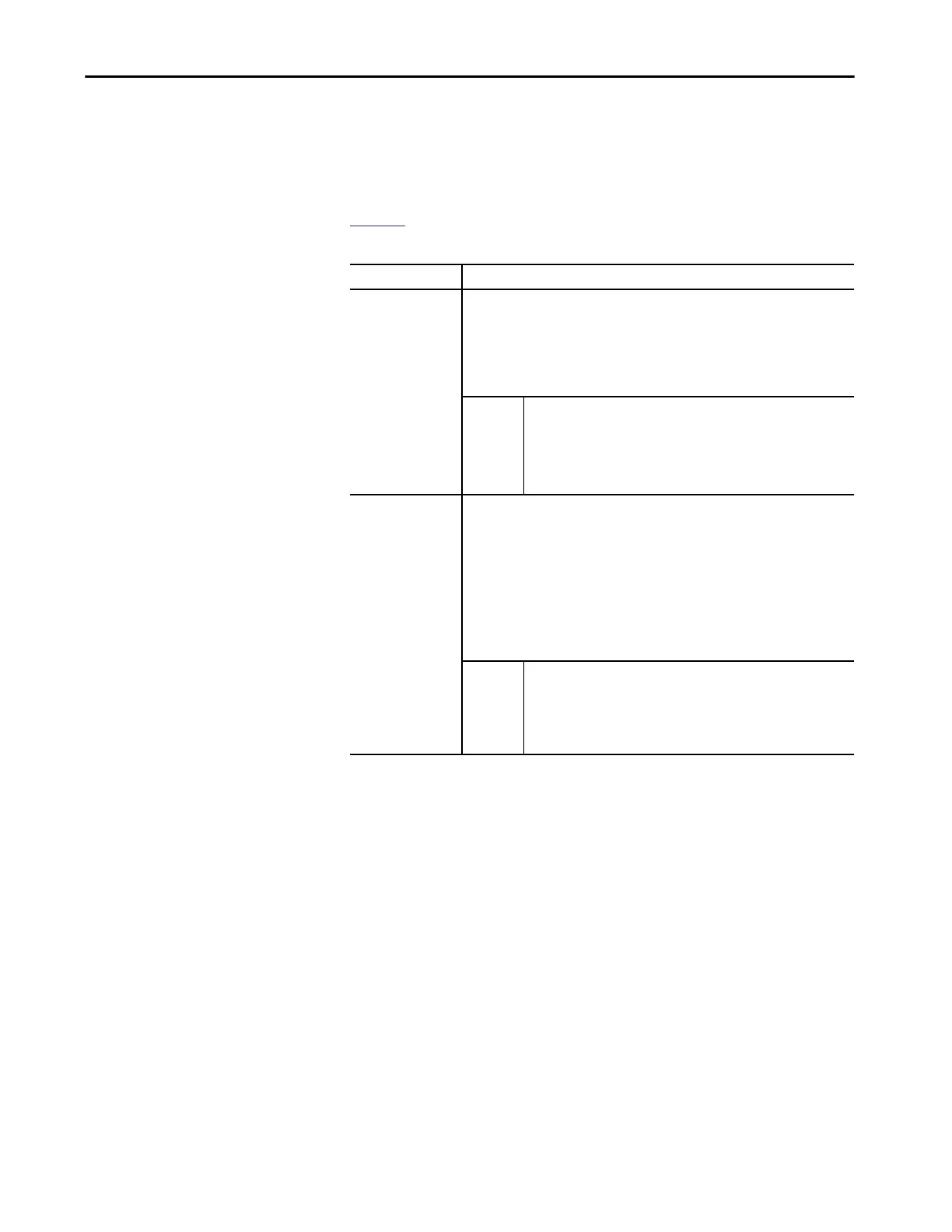

Table 12 - Timestamp Options

Topic Description

Timestamping for a

sequence of events

You can use CIP Sync to establish a sequence of events occurring at a particular input

module point by timestamping the input data. To determine a sequence of events, you

must complete the following:

• Set the format of the input module to Timestamped Input Data.

• Enable COS for the input where a sequence occurs, and disable COS for all other points

on the module.

TIP

If you configure multiple inputs for COS, your module generates a unique

time stamp each time any of those inputs change state if the changes do

not occur within 500 μs of each other.

If multiple inputs that are configured for COS change state within 500 ìs of

each other, one time stamp is generated for all state changes. As a result, it

appears as if they changed simultaneously.

Timestamping with

scheduled outputs

You can use timestamping with the scheduled outputs feature, so that after input data

changes state and a time stamp occurs, an output point actuates at a specific time.

You can schedule outputs into the future. Outputs that are sent in one packet can differ by

approximately 2 seconds. Sending in multiple messages allows greater spacing between

schedules. When you use timestamping of inputs and scheduled outputs, you must

complete the following:

• Choose a connection format for each input and output module that enables

timestamping.

• Disable COS for all input points on the input module except the point being

timestamped.

TIP

For scheduled outputs to work most effectively, remember the following:

• The schedule fires when it is configured to. You must make sure that

there is enough time for the schedule to plan ahead. If you are using an

MAOC instruction, you cannot control the schedule.

• A system-level Grandmaster synchronizes the times of the I/O modules.

Loading...

Loading...