Rockwell Automation Publication 520-UM001G-EN-E - September 2014 217

PID Set Up Appendix F

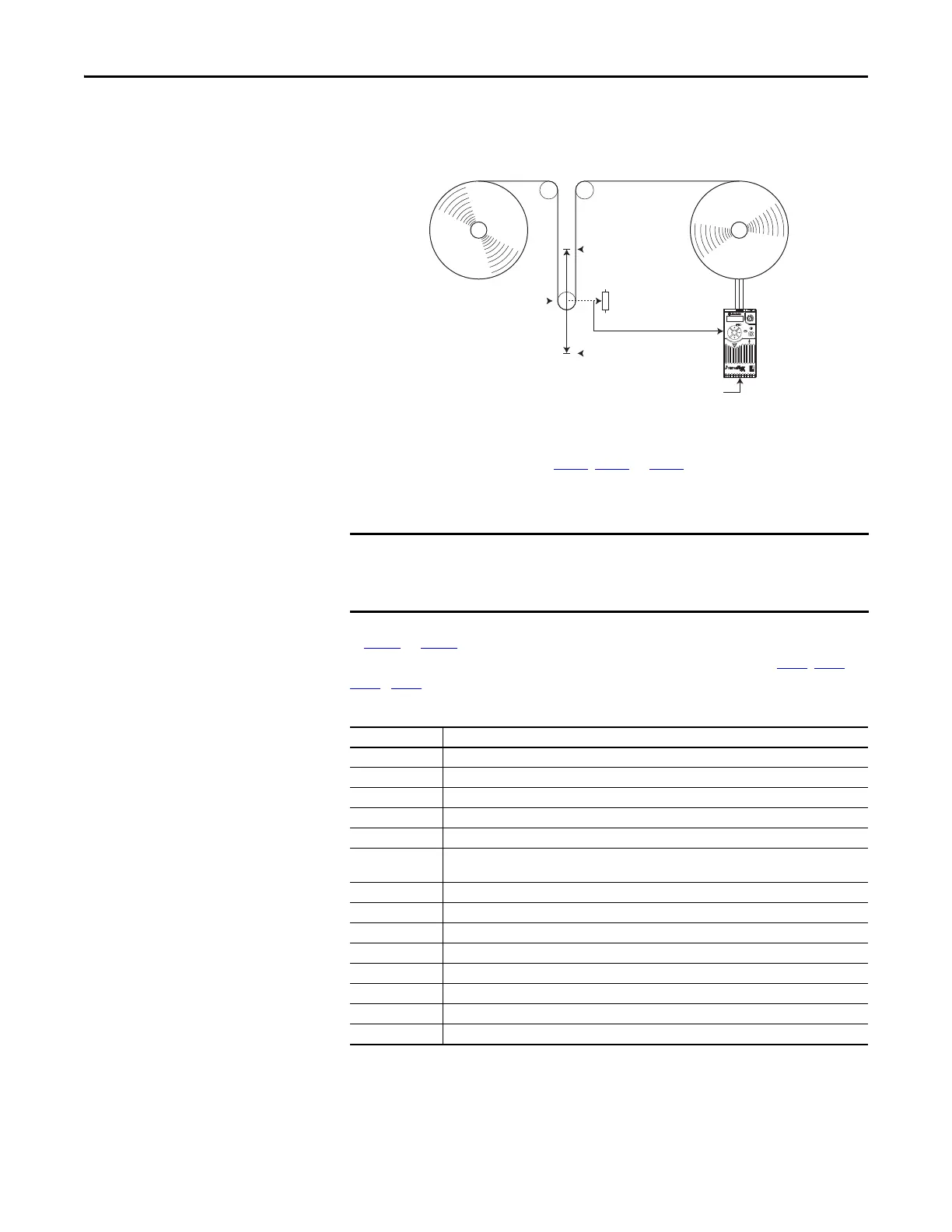

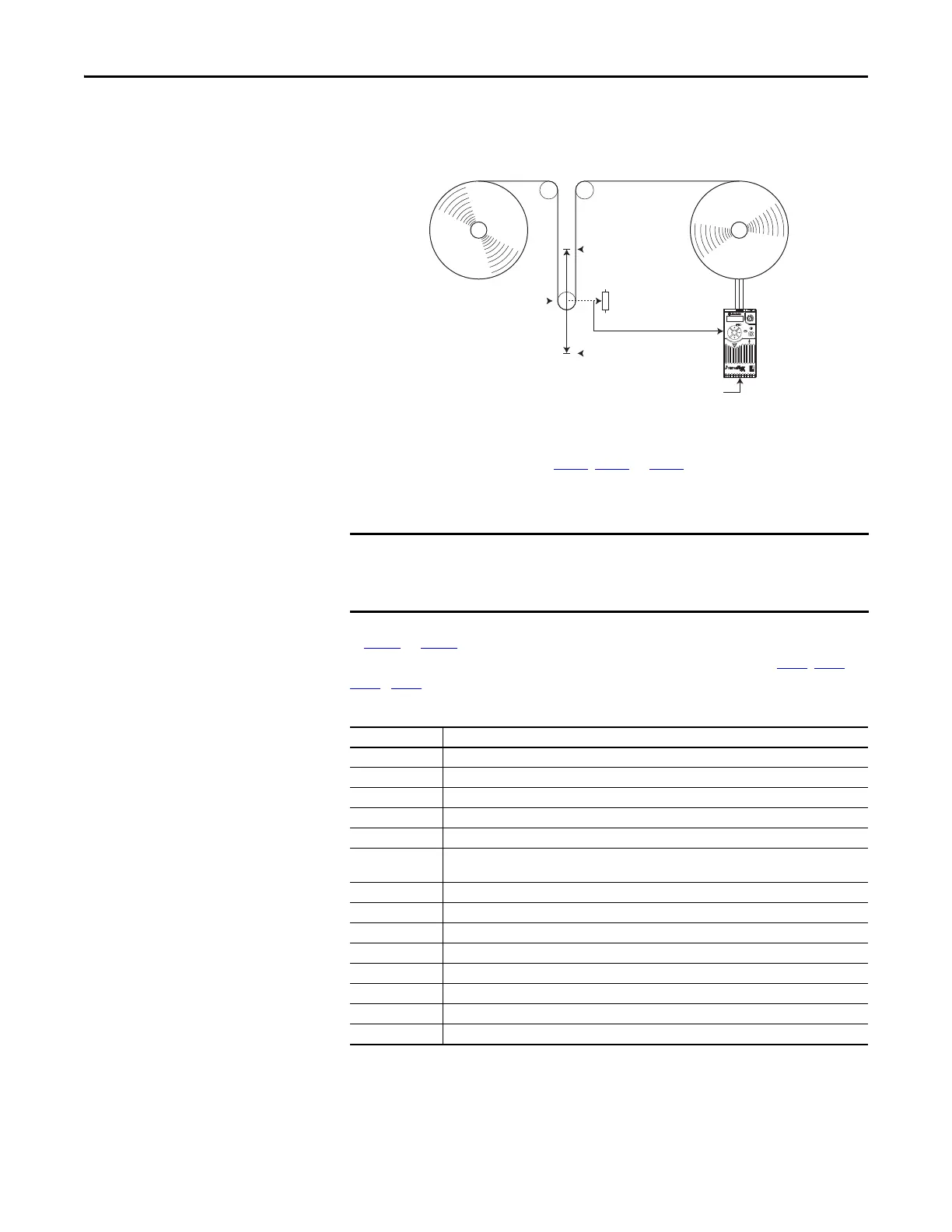

• As tension increases or decreases during winding, the Speed Reference is

trimmed to compensate. Tension is maintained near the Equilibrium set

point.

PID Reference and Feedback

PID mode is enabled by setting P047, P049 or P051 [Speed Referencex] to

11 “PID1 Output” or 12 “PID2 Output”, and activating the corresponding speed

reference.

If A459

or A471 [PID x Ref Sel] is not set to 0 “PID Setpoint”, PID can still be

disabled by select programmable digital input options (parameters t062

, t063,

t065

...t068 [DigIn TermBlk xx]) such as “Purge”.

[Speed Referencex]

0V

PID Feedback =

Dancer Pot Signal

10V

PID Reference =

Equilibrium Set Point

PowerFlex 523 has one PID control loop.

PowerFlex 525 has two PID control loops, of which only one can be in use at any

time.

A459, A471 [PID x Ref Sel] Options

Options Description

0 “PID Setpoint“ A464 or A476 [PID x Setpoint] will be used to set the value of the PID Reference.

1 “Drive Pot” The drive potentiometer will be used to set the value of the PID Reference.

2 “Keypad Freq” The drive keypad will be used to set the value of the PID Reference.

2 ”Serial/DSI” The reference word from the Serial/DSI communication network becomes the PID Reference.

4 “Network Opt” The reference word from a communication network option becomes the PID Reference.

5 “0-10V Input” Selects the 0-10V Input. Note that the PID will not function with a bipolar analog input. It will

ignore any negative voltages and treat them like a zero.

6 “4-20mA Input” Selects the 4-20 mA Input.

7 “Preset Freq” A410...A425 [Preset Freq x] will be used as an input for the PID Reference.

8 “AnlgIn Multi”

(1)

(1) Setting is specific to PowerFlex 525 drives only.

The product of the 0-10V and 4-20mA Inputs will be used as an input for the PID Reference.

9 “MOP Freq” A427 [MOP Freq] will be used as an input for the PID Reference.

10 ”Pulse Input” Pulse train will be used as an input for the PID Reference.

11 “Step Logic”

(1)

Step Logic will be used as an input for the PID Reference.

12 “Encoder”

(1)

Encoder will be used as an input for the PID Reference.

13 “Ethernet/IP”

(1)

The reference word from the Ethernet/IP communication network becomes the PID Reference.

Loading...

Loading...