TPS Control EN User guide

© Atlas Copco Industrial Technique AB - 9836 5819 01

11

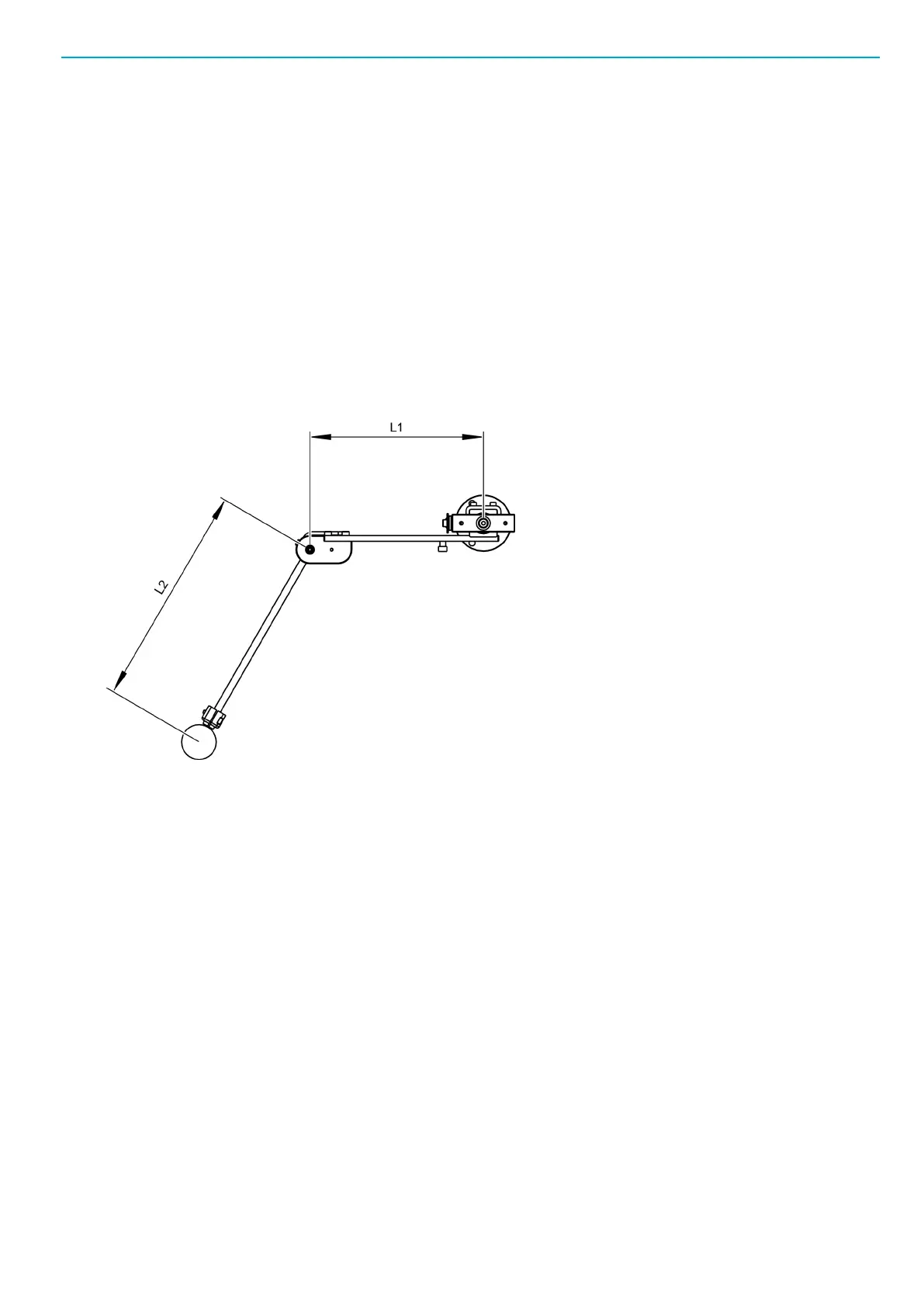

1. In TPS Control, go to Position.

2. Set Arm type to Angle/Linear.

3. Measure Length 1 (L1) on the torque arm from the centre of the axis to the centre of the tool when

fully retracted to start position. Check that the encoder value is set to zero in this position in Ser-

vice>Test functions>Test Inputs.

4. Measure Length 2 (L2) on the torque arm from the centre of the axis to the centre of the tool when

fully protracted to maximum length.

If the fully protracted arm has an analogue encoder value less than 1023, the following formula should

be used to calculate L2:

L2

Input

= L1 + 1023 * (L2 - L1)/(D2 - D1), where D stands for encoder value.

5. Enter the values for L1 and L2 in Length 1 and Length 2.

6. Press VAL to confirm changes or ESC to quit without making any changes.

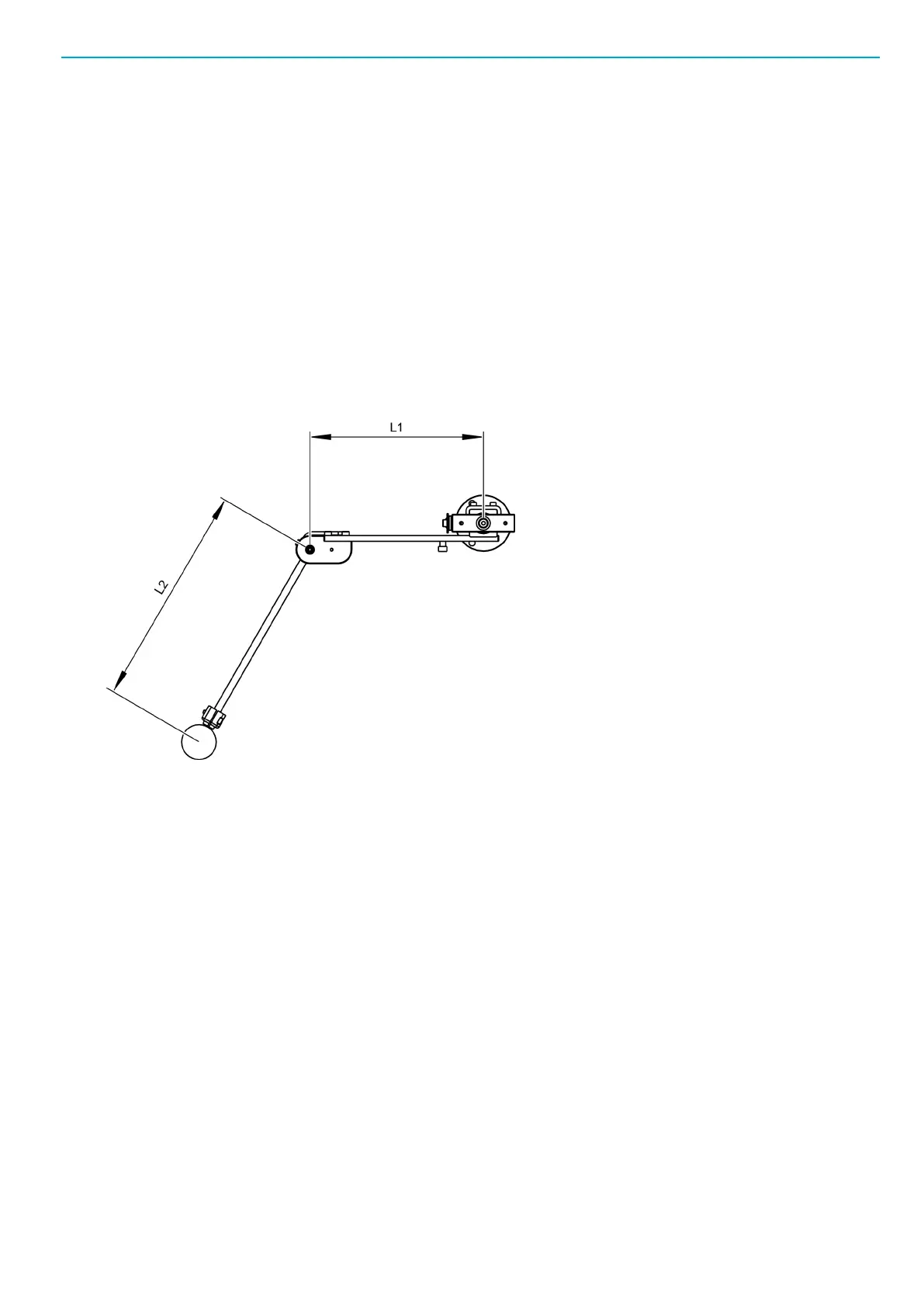

Setting up SMS T arms

The figure above shows an SMS T arm from above with horizontal arm mounted to the left (angle/angle

A).

1. In TPS Control, go to Position.

2. Set Arm type to one of the following angle/angle values:

■

Angle/Angle A (SMS T, position from above: horizontal arm mounted to the left, 180-degree ana-

logue encoder mounted on top of the torque arm)

■

Angle/Angle B (Positioning arm with 360-degree analogue encoder)

■

Angle/Angle C (SMS T, position from above: horizontal arm mounted to the right, 180-degree ana-

logue encoder mounted on bottom of the torque arm)

For more information on how to mount the positioning encoder on either the top or the bottom of the

torque arm, see the applicable torque arm instructions.

3. Measure Length 1 (L1) from the centre of the axis to the centre of the elbow when fully retracted to

start position.

4. Measure Length 2 (L2) from the centre of the elbow to the centre of the tool when fully protracted to

maximum length.

5. Enter the values for L1 and L2 in Length 1 and Length 2.

6. Press VAL to confirm changes or ESC to quit without making any changes.

7. Go to Service>Test functions>Test inputs to check that the fully retracted arm has an analogue en-

coder value of 100.

For information on how to set the encoder value to 100, see the applicable torque arm instructions.

Loading...

Loading...