13

4 MAINTENANCE AND CLEANING

Periodic maintenance is an “obligation” required by the law and is essential

tothesafety,efficiencyanddurationoftheboiler.Itallowsforthereductionof

consumption,pollutingemissionsandkeepingtheproductsafe and reliable

over time. Before starting maintenance operations:

close the fuel and water taps of the heating and domestic hot water sy-

stem.

To ensure product characteristics and efficiency remain intact and to comply

withprescriptionsofcurrentregulations,itisnecessarytorendertheapplian-

ce to systematic checks at regular intervals. When carrying out maintenance

work,respecttheindicationsgiveninchapter

“1 WARNINGS AND SAFETY

”.

This normally means the following tasks:

removing any oxidation from the burner

removing any encrustation from the heat exchangers

checkthestateofdeteriorationoftheelectrodeand,ifitisdeteriorated,

replace it together with the relative seal

check and general cleaning of the exhaust and intake pipes

checking the external appearance of the boiler

checkingtheignition,switch-offandoperationoftheappliance,inboth

DHW and heating mode

checkingthesealonthecouplingsandonthegas,waterandcondensate

connection pipes

checking the gas consumption at maximum and minimum output

checking the gas failure safety device.

b

During boiler maintenance, the use of protective clothing is

recommended to avoid any risk of personal injury.

b

Aftercarryingoutthemaintenancetasks,ananalysisofthecombustion

products is needed to make sure the boiler is working correctly.

b

In the event that, after any replacement of the electronic board,

exchanger,fan/mixer,gasvalve,orhavingcarriedoutmaintenance

on the detection electrode or on the burner, the analysis of the

combustion products returns values that are out of tolerance, it is

necessary to repeat the procedure described in paragraph “3.8

Combustion analysis”.

b

Do not clean the appliance or its parts with inflammable substances

(e.g.petrol,alcohol,etc.).

b

Donotcleanpanels,paintedpartsandplasticpartswithpaintthinner.

b

Panel cleaning must be carried out only with soapy water.

Cleaning the primary heat exchanger

Switch off the electrical supply by turning the system’s main switch to “Off”.

Close the gas shut-off valve.

Remove the casing as explained in paragraph “2.5 Removing the casing”.

Disconnect the connecting cable of the electrode.

Disconnect the power cables of the fan.

Take out the clip of the fixing ramp (A) from the mixer.

Loosen the nut of the gas train (B).

Rotate and take out the gas ramp from the mixer.

Remove the 4 nuts (C) that fix the combustion unit.

Take out the air/gas conveyor assembly including the fan and mixer,

being careful not to damage the insulating panel and the electrode.

Remove the siphon connecting pipe from the condensate drain fitting of

the heat exchanger and connect a temporary collecting pipe. At this point

proceed with the heat exchanger cleaning operations.

Vacuum out any dirt residue inside the heat exchanger,being careful

NOT to damage the retarder insulating panel.

Clean the coils of the heat exchanger with a soft bristled brush.

DO NOT USE METAL BRUSHES THAT COULD DAMAGE THE COM-

PONENTS.

Clean the spaces between the coils using a 0.4 mm thick blade (also

available in a kit).

Vacuum away any residue produced by the cleaning.

Rinsewithwater,beingcarefulNOTtodamagetheretarderinsulation

panel.

b

In case of stubborn deposits of combustion products on the surface

oftheexchanger,cleanbysprayingnaturalwhitevinegar,takingcare

NOT to damage the retarder insulation panel

Leave for a few minutes.

Clean the coils of the exchanger with a soft bristle brush.

DO NOT USE METALLIC BRUSHES WHICH CAN DAMAGE THE

COMPONENTS.

Rinse with water, taking care NOT to damage the retarder insulation

panel.

Make sure the retarder insulation panel is undamaged and replace it if

necessary following the relative procedure.

Oncethecleaningoperationsarefinished,carefullyreassembleallthe

components,followingtheaboveinstructionsinthereverseorder.

Toclosethefixingnutsoftheair/gasconveyorassembly,useatightening

torque of 6 Nm followingthesequenceindicatedonthediecast(1,2,3,4).

Turn the power and gas feeding to the boiler back on.

Cleaning the burner

Switch off the electrical supply by turning the system’s main switch to

“Off”.

Close the gas shut-off valve.

Remove the casing as explained in paragraph “2.5 Removing the casing”.

Disconnect the connecting cable of the electrode.

Disconnect the power cables of the fan.

Take out the clip of the fixing ramp (A) from the mixer.

Loosen the nut of the gas train (B).

Rotate and take out the gas ramp from the mixer.

Remove the 4 nuts (C) that fix the combustion unit.

Takeouttheair/gasconveyorassemblyincludingthefanandmixer,being

careful not to damage the ceramic insulation panel and the electrode. At

this point proceed with the burner cleaning operations.

Cleantheburnerwithasoftbristledbrush,beingcarefulnottodamage

the insulation panel and the electrode.

DO NOT USE METAL BRUSHES THAT COULD DAMAGE THE COM-

PONENTS.

Check that the burner insulating panel and the sealing gasket are unda-

magedandreplacethemifnecessary,followingtherelativeprocedure.

Oncethecleaningoperationsarefinished,carefullyreassembleallthe

components,followingtheaboveinstructionsinthereverseorder.

Toclosethefixingnutsoftheair/gasconveyorassembly,useatightening

torque of 6 Nm.

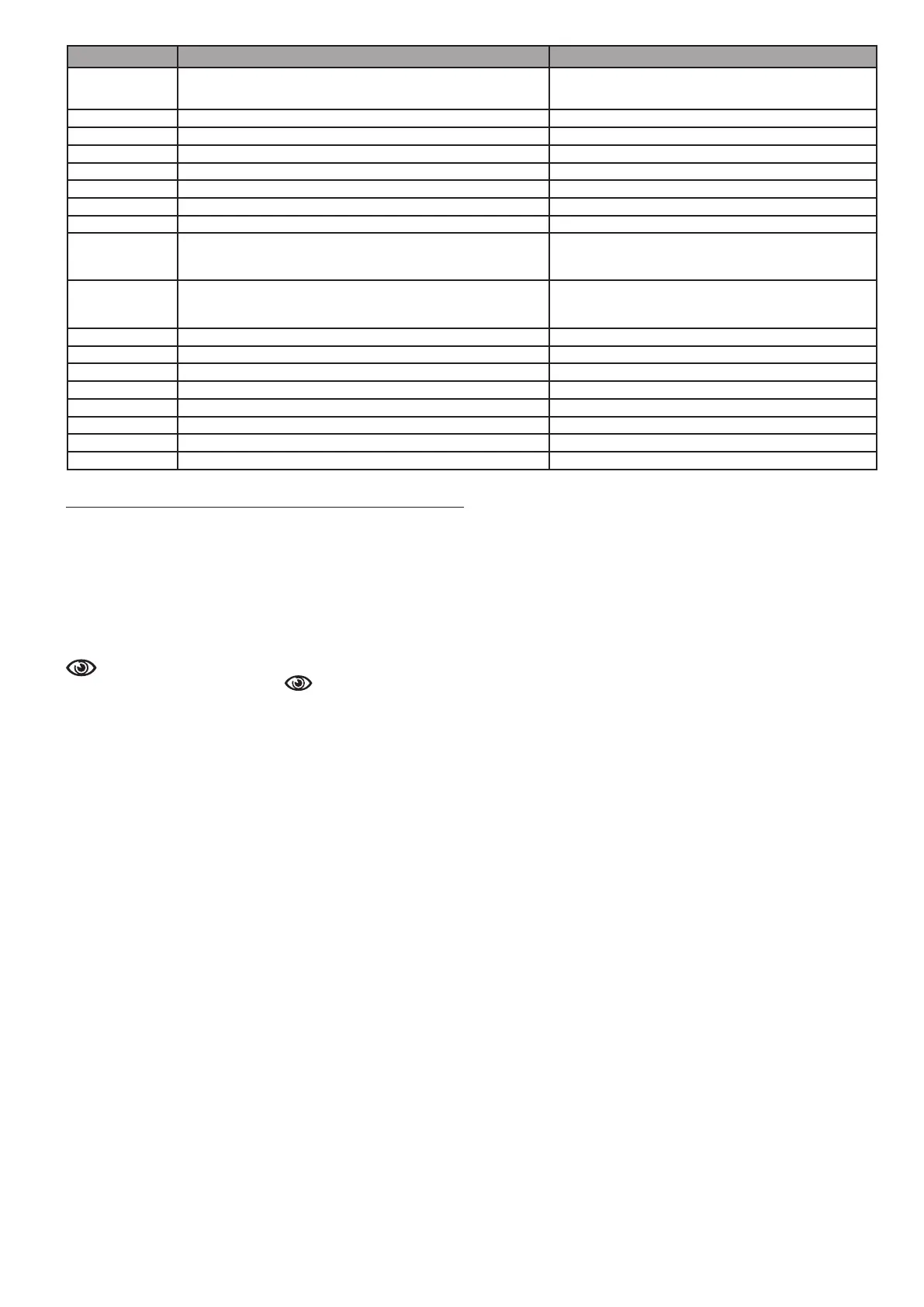

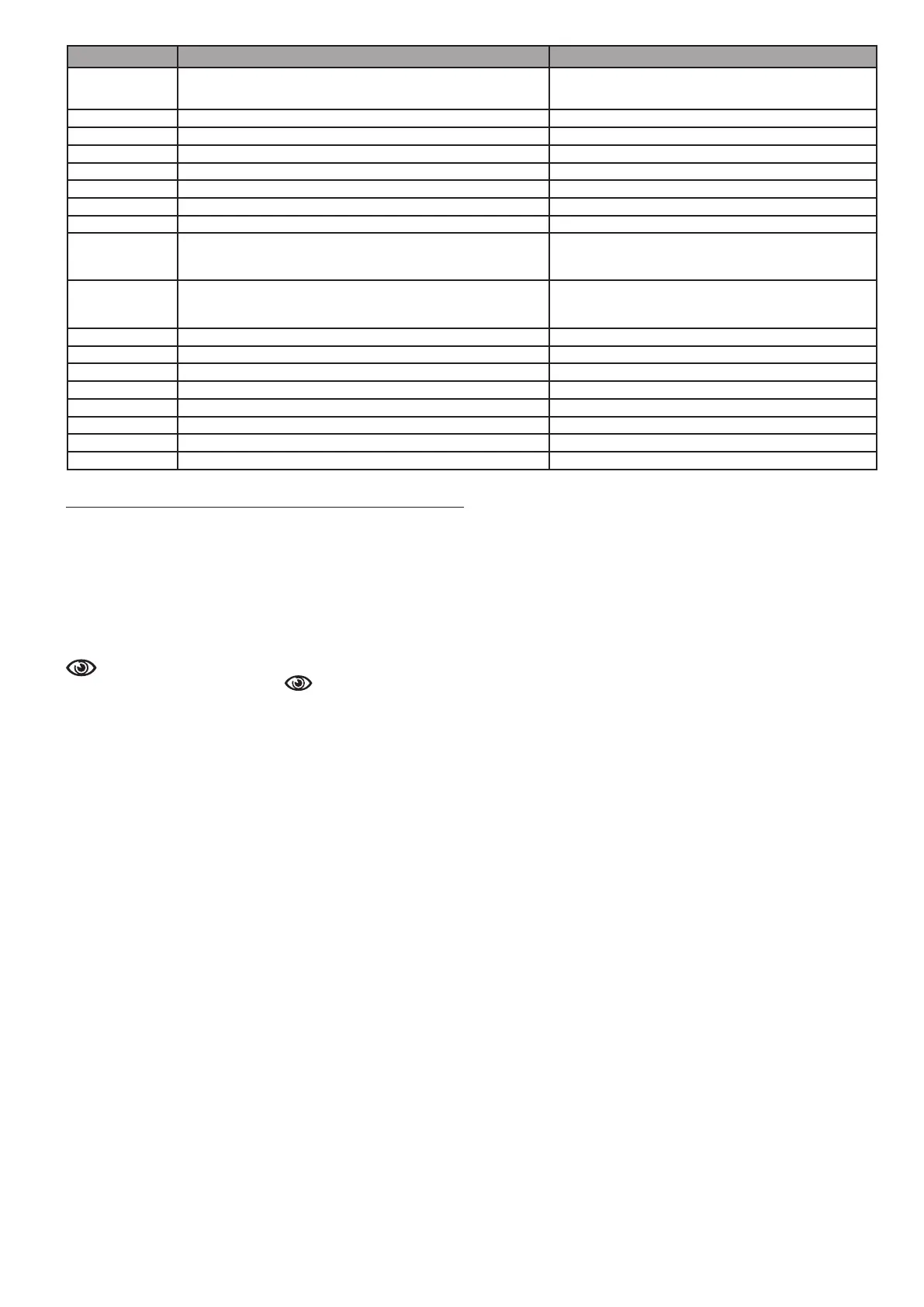

ERROR CODE ERROR MESSAGE DESCRIPTION OF TYPE OF ALARM

A10

Flame lockout

Condensate drain obstructed

Flue gas exhaust/air suction obstructed

defi nitive

A11 Extraneous fl ame transitional

A20 Limit thermostat defi nitive

A30 Fan fault defi nitive

A40 Fill the system defi nitive

A41 Fill the system transitional

A42 Pressure transducer fault defi nitive

A60 DHW probe fault transitional

A70

Flow sensor fault

Flow sensor overtemperature

Flow/return sensor diff erential

transitional

defi nitive

defi nitive

A80

Return probe fault

Return probe overtemperature

Return-fl ow sensor diff erential

transitional

defi nitive

defi nitive

A90 Flue gas probe fault transitional

A91 Clean primary heat exchanger transitional

A58 Low power supply voltage transitional

A59 High power supply voltage transitional

CFS Call Service signal

SFS Stop for Service defi nitive

FIL Low pressure - check system signal

>3.0 bar High pressure - check system signal

Loading...

Loading...