6

2 INSTALLATION

2.1 Cleaning the system and characteristics of water

Inthecaseofanewinstallationorreplacementoftheboiler,itisnecessary

toclean theheatingsystem.Toensure the deviceworkswell, top upthe

additivesand/orchemicaltreatments(e.g.anti-freezeliquids,lmingagents,

etc.) and check the parameters in the table are within the values indicated.

PARAMETERS udm

HEATING CIRCUIT

WATER

FILLING

WATER

pH value - 7-8 -

Hardness °F - <15

Appearance - - clear

Fe

mg/kg

<0,5 -

Cu

mg/kg

<0,1 -

TheboilermustbeconnectedtoaheatingsystemandaDHWsystem,

both sized on the basis of its performance and power.

Beforeinstallation,washeverysystempipingcarefullyinordertoremo-

ve any residues that may impair the operation of the appliance.

Under the safety valve, install a water collecting funnel with the

corresponding discharge in the event of leaks due to the overpressure

of the heating system. The domestic hot water circuit does not need a

safetyvalve,butmakesurethatthepressureofwaterworksdoesnot

exceed6bar.Incaseofdoubts,installapressurereducer.

b

Priortoignition,makesurethattheboilerisdesignedtooperate

with the gas available; this can be checked by the wording on the

packaging and by the adhesive label indicating the gas type.

b

Itisveryimportanttohighlightthatinsomecasestheuesareun-

derpressure,sothejointsofthevariouselementsmustbeairtight.

2.2 Installation regulations

Theinstallationmustbecarriedoutbyqualiedpersonnel,incompliance

with the following reference standards: UNI 7129-7131 and CEI 64-8.

b

During boiler installation the use of protective clothing is

recommended,inordertoavoidpersonalinjury.

Always comply with local standards of the Fire Department, the Gas

Company and with possible municipal dispositions.

POSITION

This type C condensation boiler is designed for heating and domestic

hotwaterproduction.Therearetwocategories,dependingonthetype

of installation:

1. B23P-B53Pboilertype-forcedopeninstallation,withuegasdischarge

pipe and pickup of combustion air from the installation area. If the boiler

isnotinstalledoutdoors,airintakeintheinstallationareaiscompulsory;

2. C13,C13x; C33,C33x; C43,C43x; C53,C53x; C83,C83x,C93,C93x

boilertype:appliance withairtightchamber,withuegas discharge

pipe and pick-up of combustion air from outside. It does not require an

air intake point in the installation area.

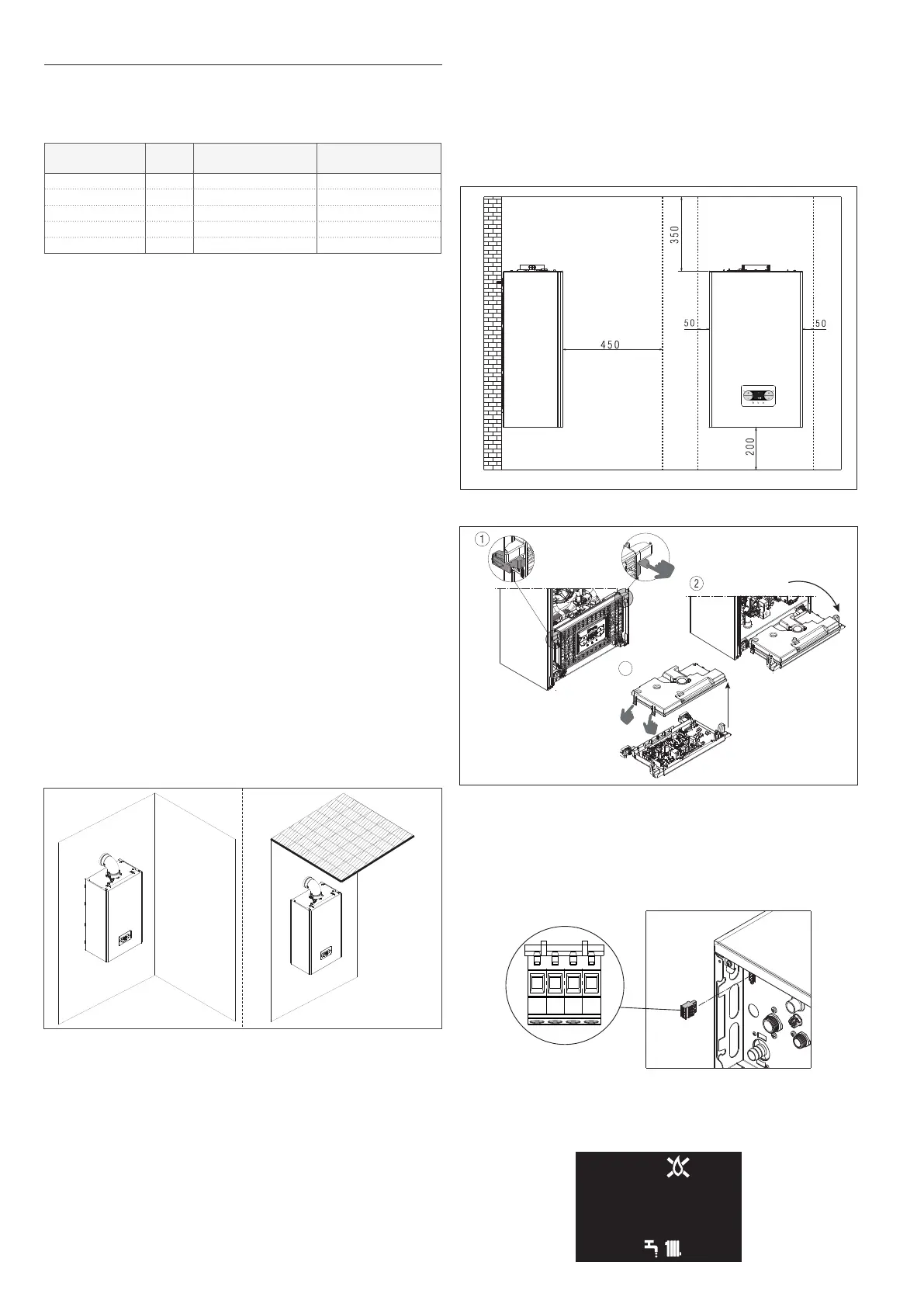

The appliance can be installed indoors (g. A) or outdoors (but in a partially

protected place (g. B)whereitisnotdirectlyexposedtorain,snoworhail).

It can work within a temperature range from >0°C to +60°C.

g. B

g. A

ANTI-FREEZE SYSTEM

Theboileristtedasstandardwithanautomaticanti-freezesystemthatacti-

vates when the temperature of the water in the primary circuit falls below 5°C.

This system is always active and provides protection for the boiler up to an air

temperature in the installation area of 0°C.

To take advantage of this protection (based on burner operation), the boiler

must be able to switch itself on; any lockout condition (for ex. due to a lack of

gasorelectricalsupply,ortheinterventionofasafetydevice)thereforedeacti-

vates the protection.

Innormaloperatingconditions,theboilercanprotectitselfagainstfrost.

You are advised to add a good quality anti-freeze liquid to the primary circuit

(respectingthemanufacturer’sindications)ifthetemperaturefallsbelow0°C,

with the electricity supply disconnected and the heating system full.

Forthehotdomesticwaterpart,werecommendyoudrainthecircuit.

The boiler component materials are resistant to ethylene glycol based antifreeze

liquids.

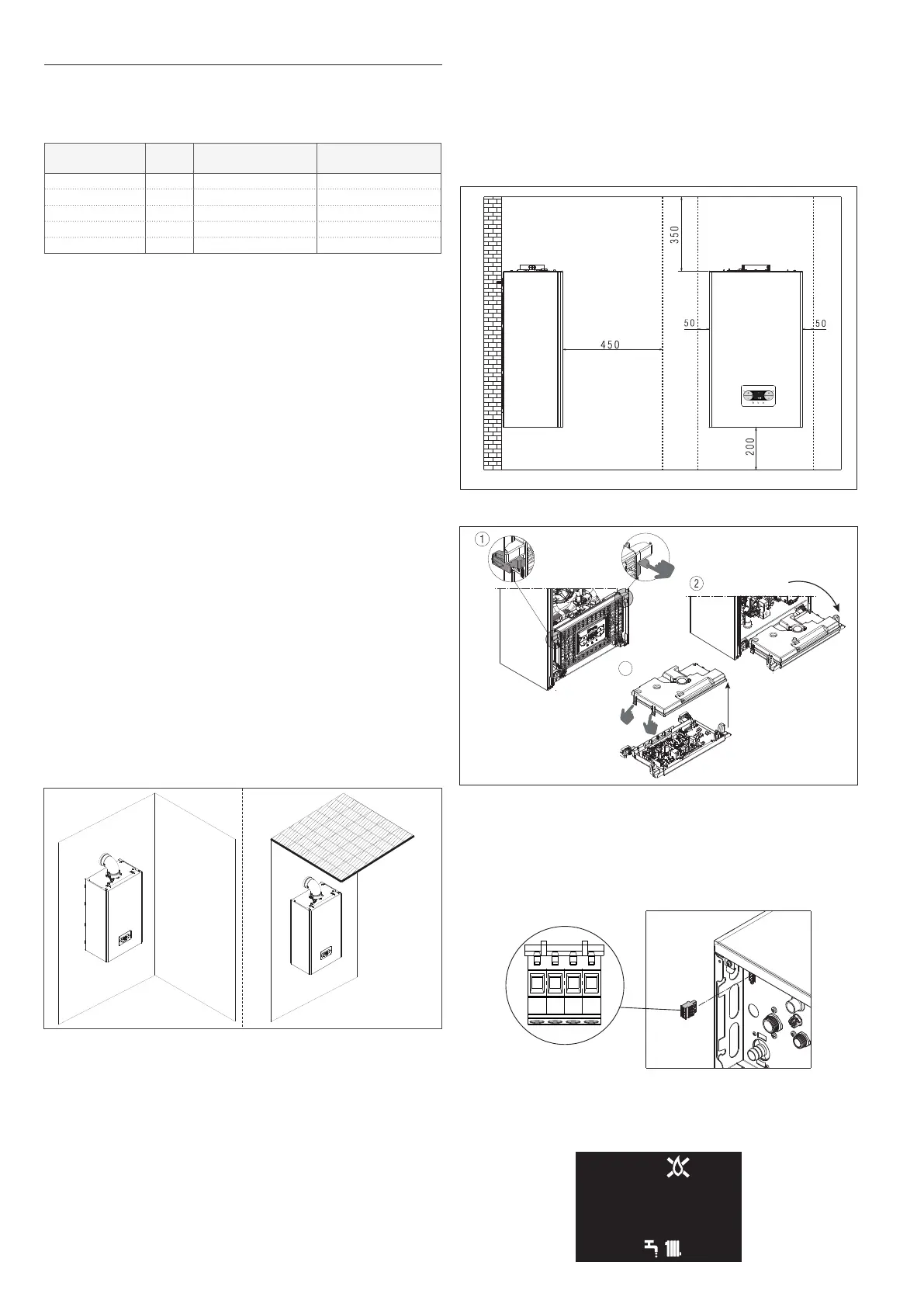

MINIMUM DISTANCES

Toensureaccesstotheboilerfornormalmaintenanceoperations,respectthe

minimum installation clearances envisaged.

Forcorrectappliancepositioning,bearinmindthat:

- it must be installed on a wall that can support its weight

- it must not be placed above a cooker or other cooking device

- itisforbiddentoleaveinammableproductsintheroomwheretheboileris

installed

- heat-sensitive walls (e.g. wooden walls) must be protected with proper in-

sulation.

measured in mm

2.3 Access to the electrical components

3

2.4 Electrical connections

Low voltage connections

CE4 connector: use4-polesconnector,suppliedasstandard,forconnections

withModBus485signal.Oncetheoperationshavebeencompleted,placethe

connector correctly in its counterpart.

b

We recommend using conductors with a section no larger than0,5mm

2

.

4-poles

ModBus

connector (CE4)

Connection on the main board: maketheTA(ambientthermostat),OT+

and SE (external sensor) connections on X11 connector - see diagram “7.5

Multiwire electrical diagram

”.

NOTE: when an OT+remotecontrolisconnectedtothesystem,ifparameter

803=1(SERVICE),

the boiler display shows the following screen

:

o

t

o

t

Loading...

Loading...