Electrical connection (only for approved contractors)

167

Tronic 1000 T | Tronic 2000 T – 6721831855 (2021/06)

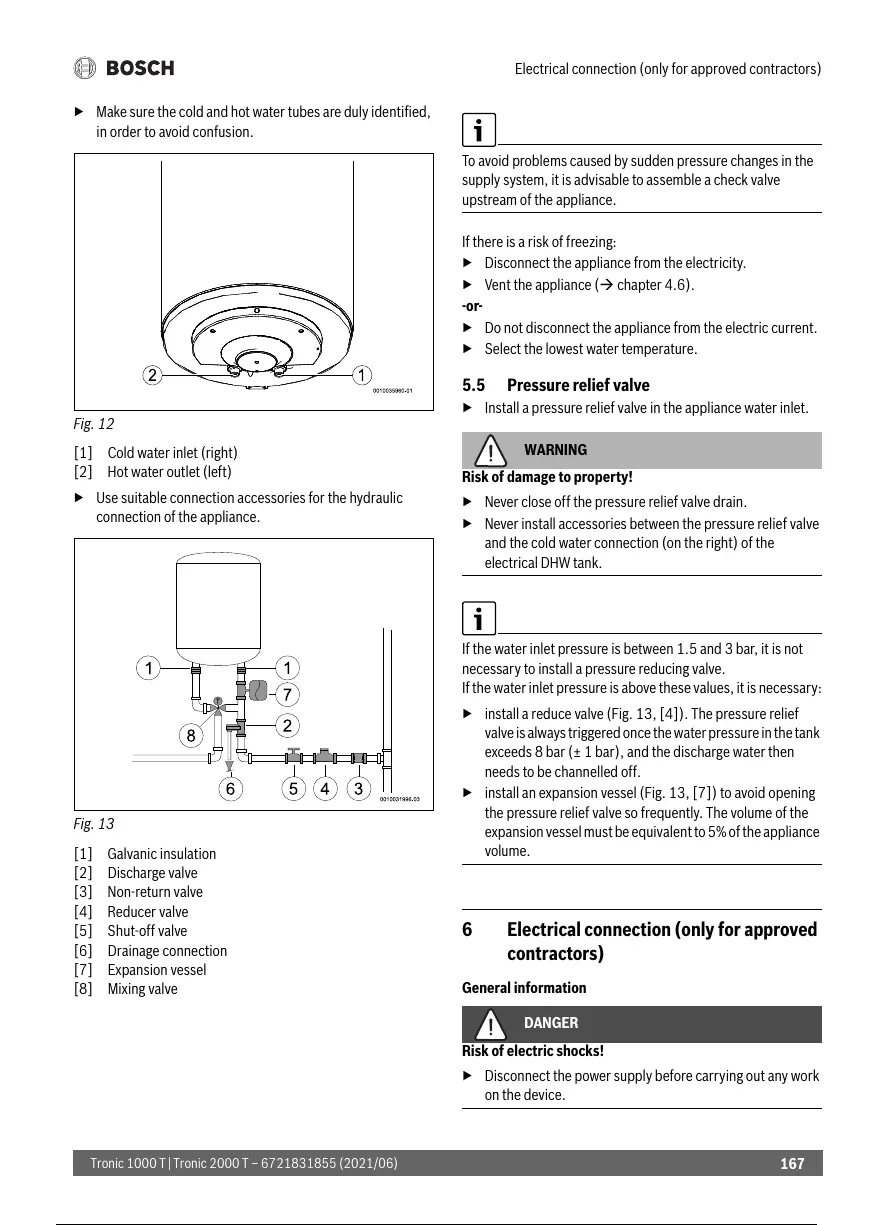

Make sure the cold and hot water tubes are duly identified,

in order to avoid confusion.

Fig. 12

[1] Cold water inlet (right)

[2] Hot water outlet (left)

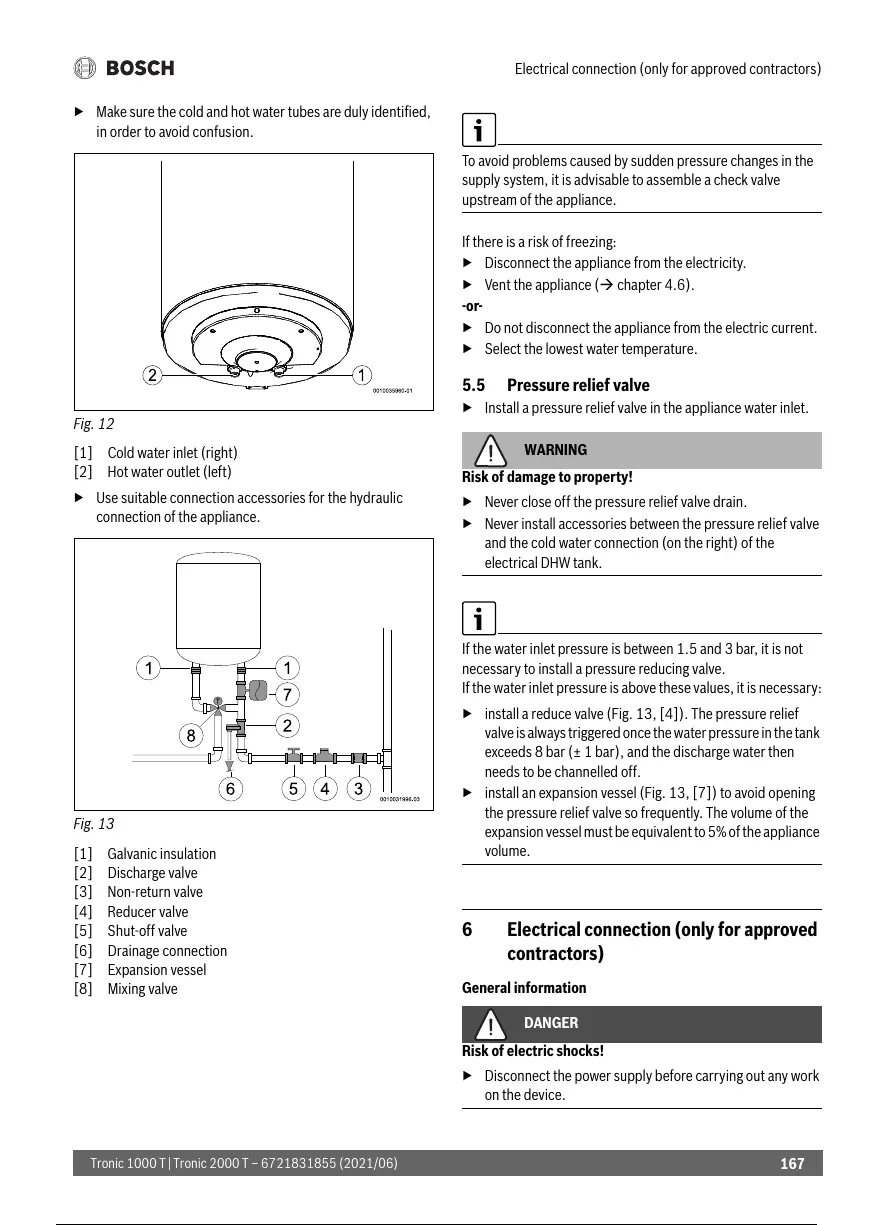

Use suitable connection accessories for the hydraulic

connection of the appliance.

Fig. 13

[1] Galvanic insulation

[2] Discharge valve

[3] Non-return valve

[4] Reducer valve

[5] Shut-off valve

[6] Drainage connection

[7] Expansion vessel

[8] Mixing valve

To avoid problems caused by sudden pressure changes in the

supply system, it is advisable to assemble a check valve

upstream of the appliance.

If there is a risk of freezing:

Disconnect the appliance from the electricity.

Vent the appliance ( chapter 4.6).

-or-

Do not disconnect the appliance from the electric current.

Select the lowest water temperature.

5.5 Pressure relief valve

Install a pressure relief valve in the appliance water inlet.

WARNING

Risk of damage to property!

Never close off the pressure relief valve drain.

Never install accessories between the pressure relief valve

and the cold water connection (on the right) of the

electrical DHW tank.

If the water inlet pressure is between 1.5 and 3 bar, it is not

necessary to install a pressure reducing valve.

If the water inlet pressure is above these values, it is necessary:

install a reduce valve (Fig. 13, [4]). The pressure relief

valve is always triggered once the water pressure in the tank

exceeds 8 bar (± 1 bar), and the discharge water then

needs to be channelled off.

install an expansion vessel (Fig. 13, [7]) to avoid opening

the pressure relief valve so frequently. The volume of the

expansion vessel must be equivalent to 5% of the appliance

volume.

6 Electrical connection (only for approved

contractors)

General information

DANGER

Risk of electric shocks!

Disconnect the power supply before carrying out any work

on the device.

168 / 242 167 / 240 168 / 242

Loading...

Loading...