31

ALIGNMENT PROCEDURES

4.7 After the adjustment is complete,

solder the point labeled TE.

5. Alignment Completion.

5.1 Solder the point labeled ATSC.

5.2 Perform test procedure 1.

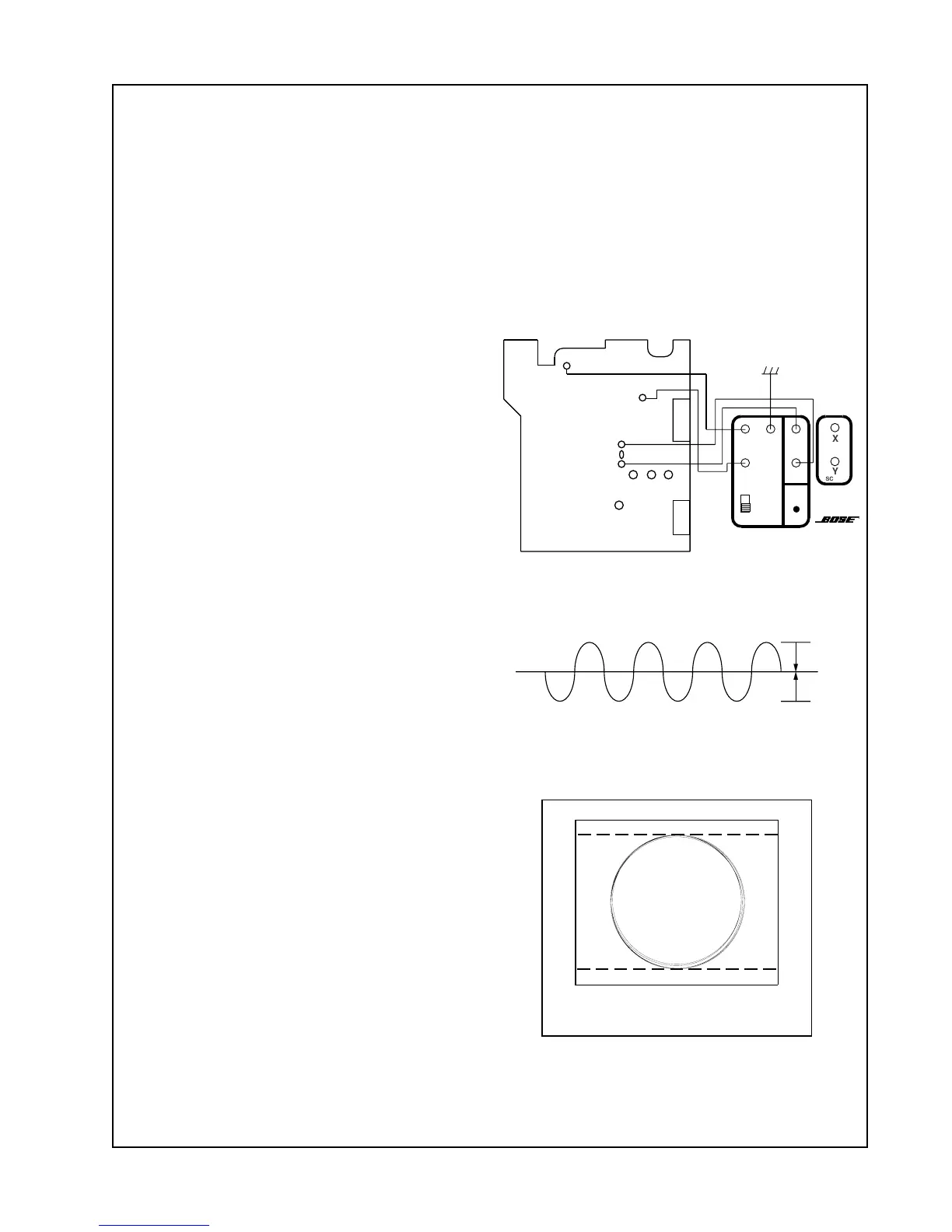

3. Focus Gain Alignment

3.1 Unplug the power pack from the CD-20

3.2 Remove the solder from the point

labeled FE and connect the CD-20 align-

ment fixture as shown in Figure 3.

3.3 Turn the CD-20 on and play track

number one of the A•Bex CD TCD-784.

3.4 Switch the CD-20 alignment fixture's

oscillator to 1.75 kHz.

3.5 Set the oscilloscope to the X-Y mode

and connect CH2 of the oscilloscope to the

"X" input and CH1 to the "Y" input of the

alignment fixture.

3.6 Adjust PT821 (F. GAIN) for the best

circle as viewed on the oscilloscope. See

Figure 6.

3.7 After the adjustment is complete,

solder the point labeled FE.

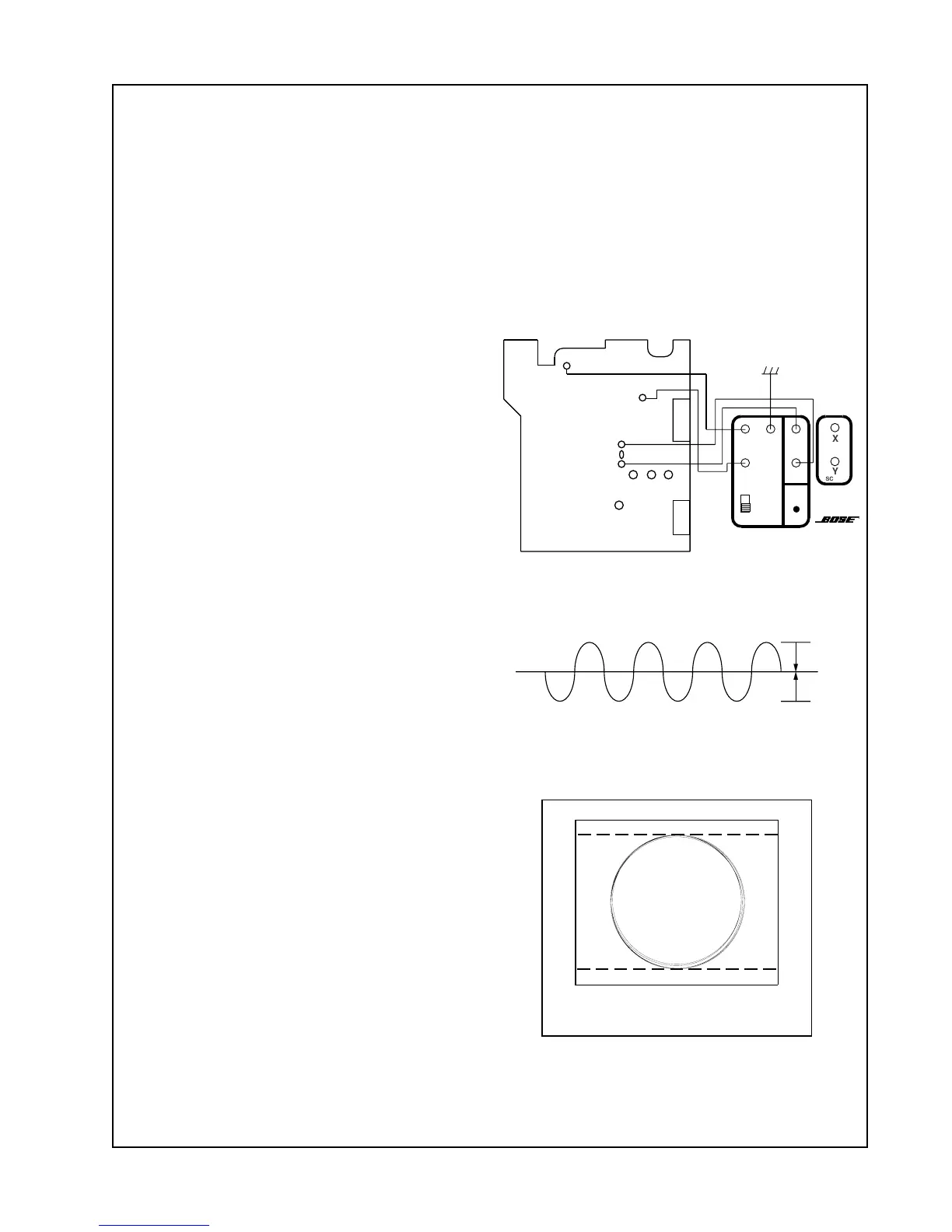

4. Tracking Gain Alignment

4.1 Unplug the power pack from the unit.

4.2 Remove the solder from the point

labeled TE and connect the alignment

fixture as shown in Figure 4.

4.3 Plug the CD-20 in and play track num-

ber 1 of the A•Bex CD TCD-784.

4.4 Switch the CD-20 alignment fixture's

oscillator to 2.15 kHz.

4.5 Set the oscilloscope to the X-Y mode.

Connect CH2 of the oscilloscope to the "X"

input and CH1 to the "Y" input of the align-

ment fixture.

4.6 Adjust PT822 (T. GAIN) for the best

circle as viewed on the oscilloscope. See

Figure 6.

CN902

CN903

TP704

Changer PCB

TP822

TP821

TE

TP701

PT822

V+

GND

1/2 V

CC

F 1.75kHz

T 2.15kHz

X

Y

SCOPE

CD20

ALIGNMENT

FIXTURE

CD-A

CD-B

POWER

Figure 5. Symmetrical Waveform

Oscilloscope

Figure 6. X-Y Mode Output

10mV/ Division

Figure 4. Tracking Gain Alignment

V1

V2

V1=V2

0V

Loading...

Loading...