2-69

Confidential

4.2 Troubleshooting for Paper Feeding Problems

End users can solve problems related to paper feeding as long as they follow the User Check

items. If the problem still cannot be solved, implement each procedure according to the step

number in the tables below.

4.2.1 Multiple sheets of paper are fed

4.2.2 Paper becomes wrinkled

4.2.3 Paper is fed at an angle

<User Check>

- Check that the paper is set in each paper tray correctly.

- Check that there is not too much paper set in each tray.

- Reverse the paper in each paper tray or rotate the paper 180°.

- Check that the thickness of the paper is 60 to 105 g/m

2

. (60 to 163 g/m

2

for MP tray)

- Flip through the paper and reset it in the tray.

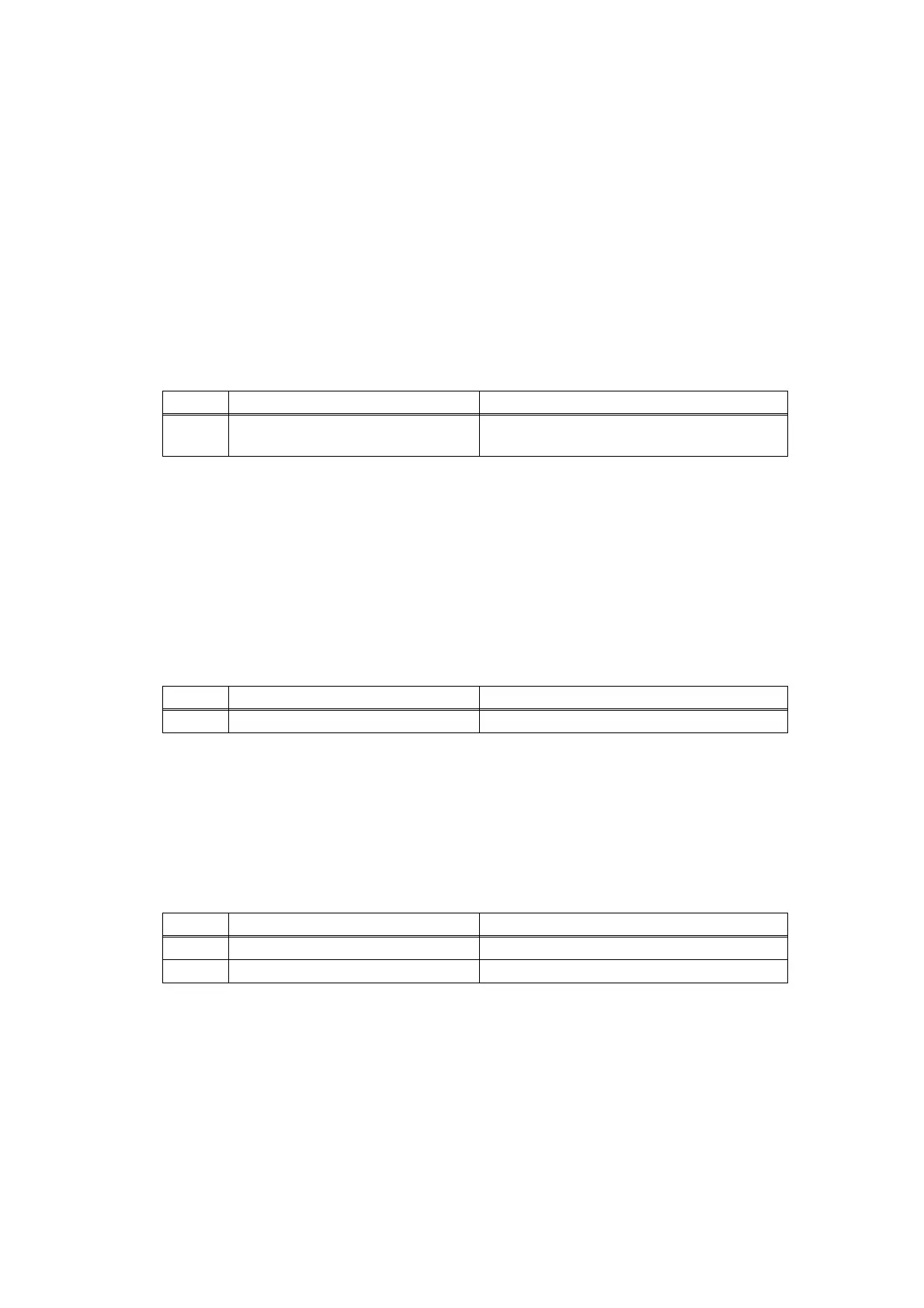

Step Cause Remedy

1

Abrasion of the separation pad or

separation roller

Replace the paper feeding kit for the

corresponding paper tray.

<User Check>

- Check that the paper is set in each paper tray correctly.

- Reverse the paper in each paper tray or rotate the paper 180°.

- Adjust the paper guide according to the paper size.

- Check that the thickness of the paper is 60 to 105 g/m

2

. (60 to 163 g/m

2

for MP tray)

- Check that the paper is not damp.

- Check that there is no dust stuck to the fuser unit.

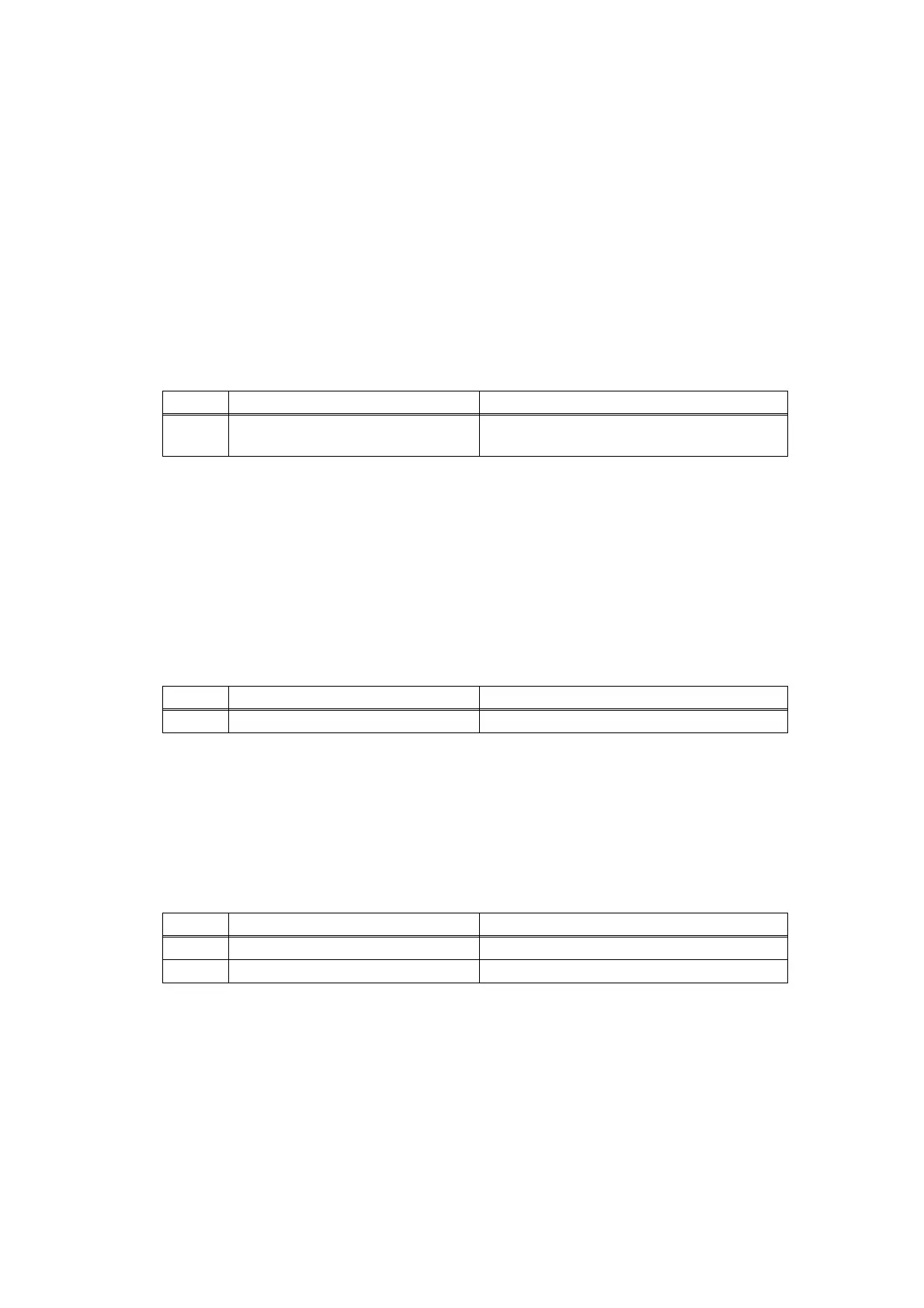

Step Cause Remedy

1 Fuser unit failure Replace the fuser unit.

<User Check>

- Check that the paper is set in each paper tray correctly.

- Adjust the paper guide according to the paper size.

- Check that the thickness of the paper is 60 to 105 g/m

2

. (60 to 163 g/m

2

for MP tray)

- Check that there is not too much paper set in each tray.

Step Cause Remedy

1 Registration clutch failure Replace the registration clutch.

2 Main PCB failure Replace the main PCB ASSY.

Loading...

Loading...