19

ENG

easy/easy compact/easy split +030220791 - rel. 3.2 - 13.07.2010

Duty setting and defrost

If the control probe error occurs when the controller is in defrost mode,

the function is not stopped but rather is completed as required; in

addition, the defrost can still be performed when called. During the

defrost, the duty setting timer is not stopped but rather keeps counting

the ON and OFF times.

Duty setting and continuous cycle

If the continuous cycle is operating, the controller instantly exits this status

and activates duty setting (also for safety reasons, given that during the

continuous cycle the low temperature alarm is disabled). To re-activate

continuous cycle operation, the ambient probe fault must be resolved.

If the probe error is no longer present, the unit returns to normal operation.

The compressor again takes on the logic of the control, respecting the

times c1, c2, c3.

4.5 Continuous cycle

The continuous cycle is used to maintain refrigeration continuously

active, regardless of the temperature inside the unit. The function is used

to rapidly lower the product temperature, even below the set point, for

example after lling the cabinets. In this phase, the temperature may fall

below the set point. To activate or deactivate the continuous cycle from

the keypad, see paragraph 3.5, the display shows “cc” and the

icon

ashes (2 ashes, pause).

cc: continuous cycle duration

This represents the time in hours that the compressor operates

continuously for so as to lower the temperature, even below the set

point. If cc=0 the continuous cycle is not activated. The controller exits

the continuous cycle procedure after the time set for parameter “cc” has

expired, or when reaching the minimum temperature (see the minimum

temperature alarm, parameter AL).

c6: temperature alarm bypass after continuous cycle

This is the time in hours during which all the temperature alarms

are deactivated after a continuous cycle. If the temperature of the

refrigerated unit, after the continuous cycle, lowers due to inertia below

the minimum temperature threshold (set point-AL), the activation of

the low temperature alarm is delayed for the time c6. In any case, the

continuous cycle is deactivated at the temperature (set point-AL).

4.6 Compressor protection

The easy, easy compact and easy split controllers are tted with an

automatic compressor protection system to avoid continual starts or

stops of the unit. The protection is based on the times in minutes set for

parameters c0; c1; c2; c3:

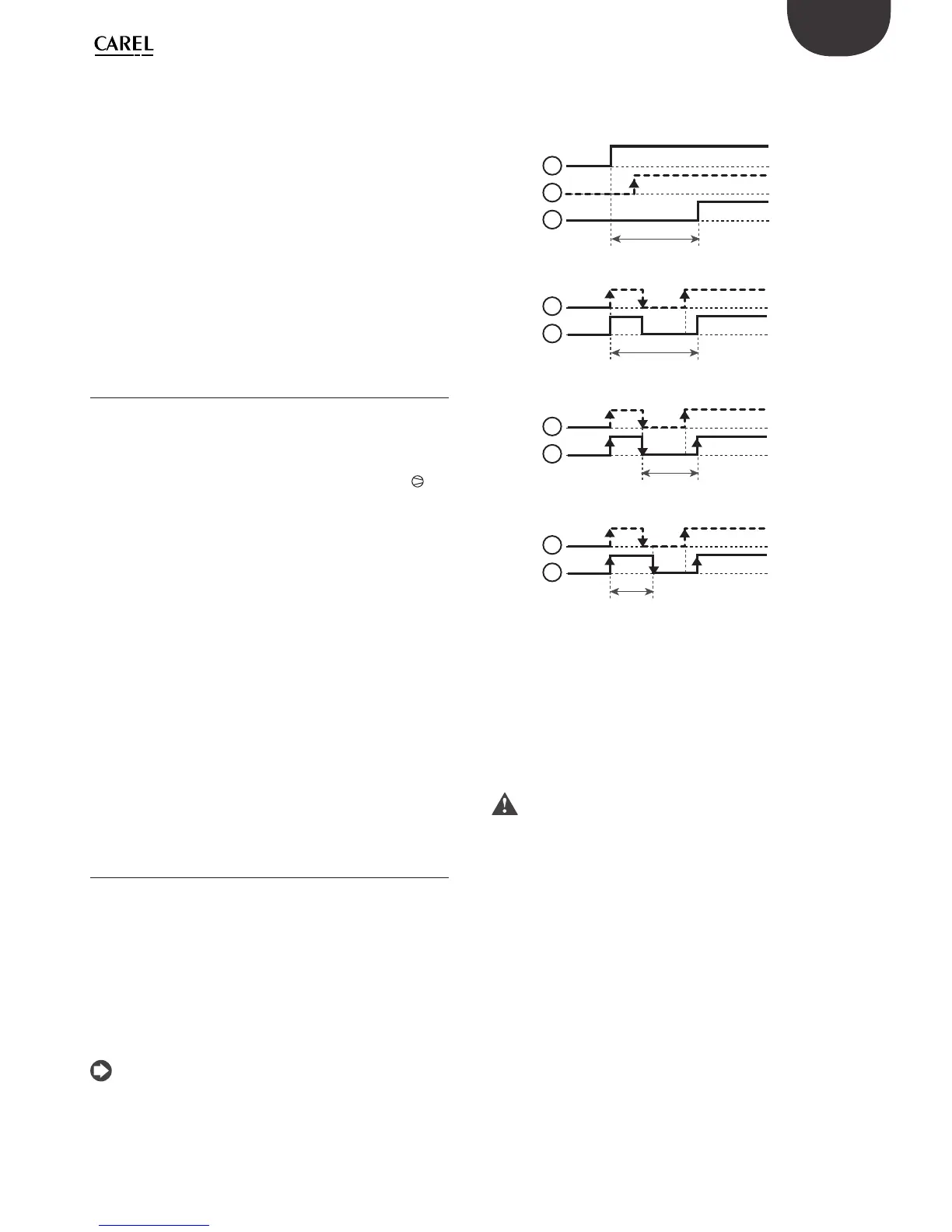

c0 compressor and fan start delay on power-up

When the controller is powered-up, this delays the start of the compressor

and the evaporator fan (see Fig. 4.c).

c1 minimum time between consecutive compressor starts

Delay between two consecutive starts of the compressor (see Fig. 4.d).

Note:

• if the maximum number of starts/hour allowed is 10, simply set c1=6

to ensure this limit is observed.

• as well as c1, also remember that parameter “dd” (dripping time) stops

the compressor and the evaporator fan after a defrost..

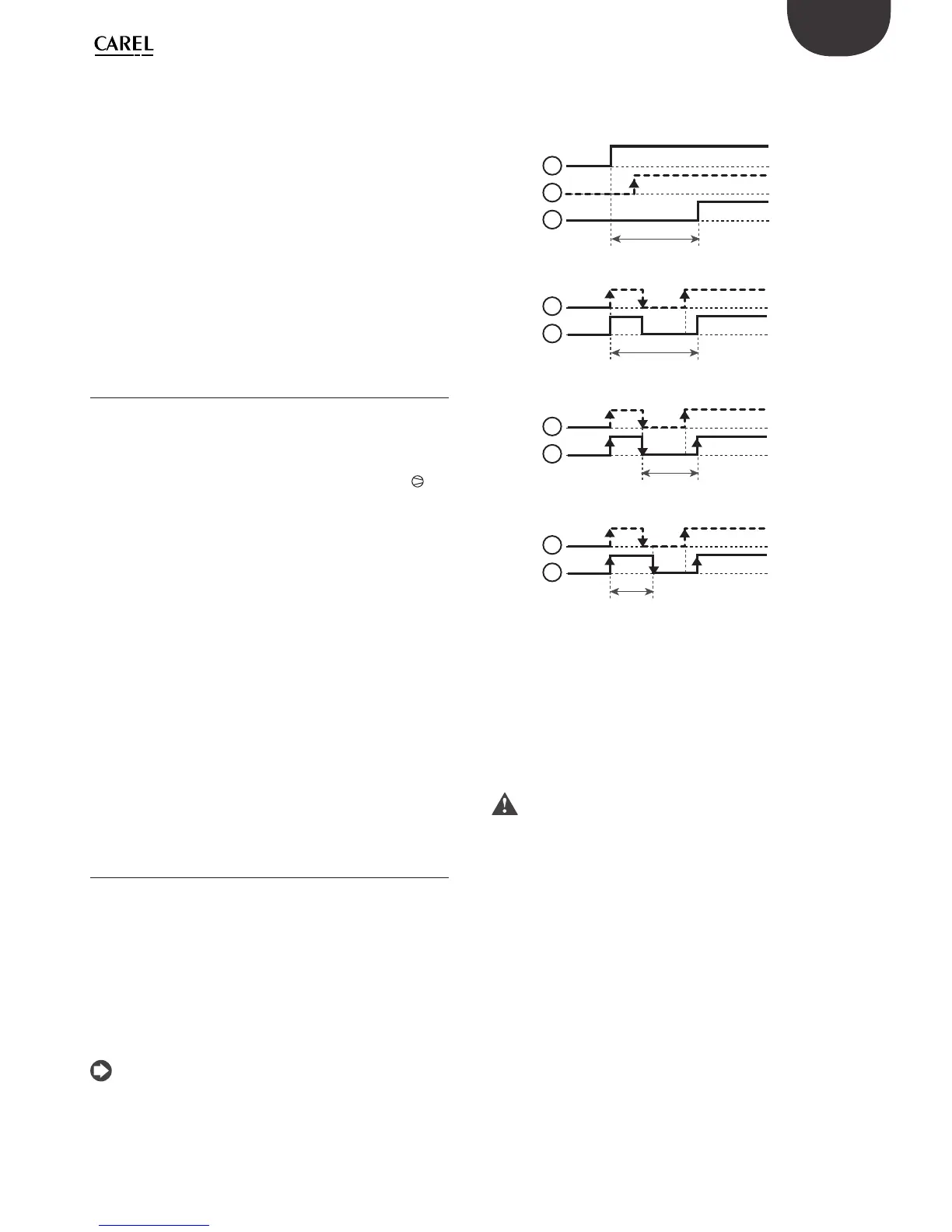

c2/c3 minimum compressor o /on time

These determine the minimum o time (c2) and on time (c3) for the

compressor. The compressor will not be controlled until times c2 and c3

have elapsed (see Figs. 4.e and 4.f).

OFF

OFF

ON

OFF

ON

ON

C0

1

2

3

Fig. 4.c

OFF

OFF

ON

ON

C1

3

2

Fig. 4.d

OFF

OFF

ON

ON

C2

3

2

Fig. 4.e

OFF

OFF

ON

ON

C3

3

2

Fig. 4.f

Key to Figs 4.c…4.f

1 instrument power-up;

2 compressor call;

3 compressor

c11: second compressor delay (easy split only)

This parameter determines the delay in the activation of the second

compressor compared to the main compressor. The parameter has no e ect

on the deactivation of the compressor.

Important: select the auxiliary output as the second compressor

output in parallel (H1 = 5), second compressor with two step control,

without rotation (H1 = 6) or second compressor with two step control, with

rotation (H1=7).

Loading...

Loading...