68

Fig 39 : Digital Vacuum gage

5.1.3 - Remove shipping packaging

After receipt remove any packaging material from the unit, VFD, and control panels.

5.1.4 – Lubrication and purge circuit valves

Check if the motorized valves on lubrication circuit are open and all solenoid valves and service valves are open

on purging circuit.

5.1.5 - Tighten all gasketed joints

Gaskets normally relax by the time the chiller arrives at the jobsite. Tighten all gasketed joints to ensure a leak-

tight chiller (does not apply to refrigerant joints covered by factory insulation). Gasketed joints (excluding O-rings)

may include joints at some or all of the following:

• Waterbox covers

• Compressor first suction elbow flanges (at compressor and at the cooler)

• Compressor secondary suction flanges (at compressor and low side float chamber)

• Compressor discharge flange

• Cooler inlet line spacer (both sides)

• Envelope control flange (both sides of valve)

• ICP piping flange

• High and low side float chamber covers

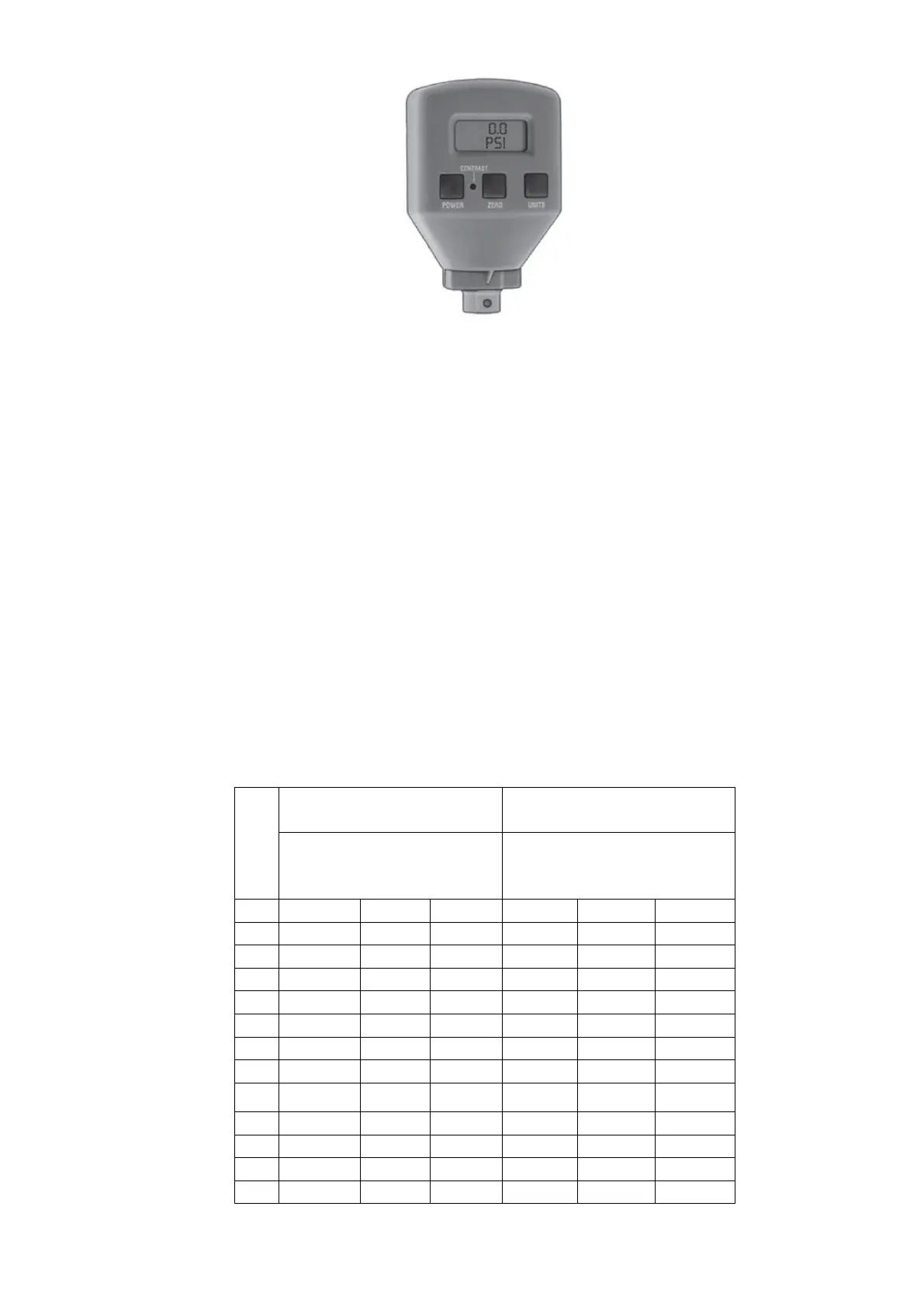

See Tables 16 for bolt torque requirements.

CLASS 8.8, SAE 5, SA499(N•m)

CLASS10.9, SAE 8, SA354 GR

BD(N•m)

SOCKET HEAD OR HEX

WITH 3 RADIAL LINES

MEDIUM CARBON STEEL

HEX HEAD

WITH 6 RADIAL LINES

MEDIUM CARBON STEEL

Loading...

Loading...