21

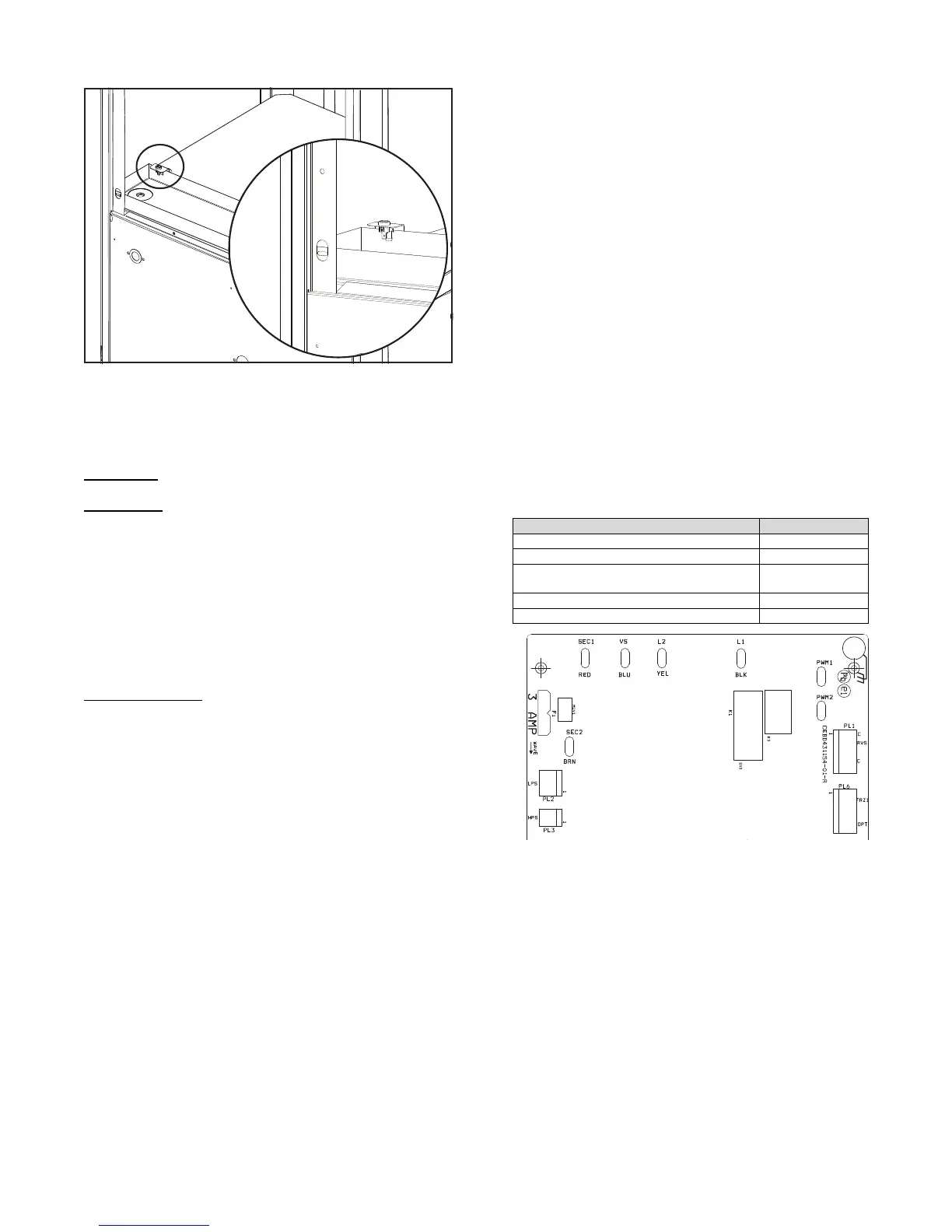

SCONDENSATE OVERFLOW PROTECTION SENSOR:

Located in the drain p an of the un it and connected to the ”COND”

terminal on the UPM board. See Fig. 25.

A14123

Fig. 25 -- Condensate Overflow Protection Sensor Location

SLOCKOUTS: If system protection faults occur, the unit will shut

down the compressor and fault codes will be shown on the UPM

board and the UI screen.

There are two types of lockouts:

Soft lockouts

-- This is a selectable dipswitch position to allow 2 or 4

unit trips before going to hard lockout.

Hard lockouts

-- Will require a manual reset.

This applies to all unit trips unless otherwise noted. In order to exit

the hard lockout early for servicing, the low voltage power to the

unit would need to be reset and the fault conditions corrected.

NOTE: The blower motor will remain active during a lockout

condition.

SBROWNOUT PROTECTION: The compressor will be shut

down if the incoming voltage falls below 170 VAC for 4 seconds

and fau lt co de will d isplay o n UP M L ED and w all con trol (if

applicable). The compressor will remain off until the voltage is

above 173 VAC for at least 4 seconds and the anti--short cycle timer

times out.

Defeat the Brownout

-- The high voltage brownout feature can be

defeated in the event of nuisance trips due to severe noisy power

conditions. The UPM dip switch has brownout ON as default, to

defeat the brown out protection, the selection can be changed to

OFF. All efforts should be exhausted to correct any electrical

deficiencies before defeating this safety feature to eliminate possible

equipment damage.

S230V LINE (POWER DISCONNECT) DETECTION:Ifthereis

no 230V at the compressor contactor(s) when the indoor unit is

powered and cooling or heating demand exists, the appropriate fault

code is displayed. Verify the disconnect is closed and 230V wiring

is connected to the unit.

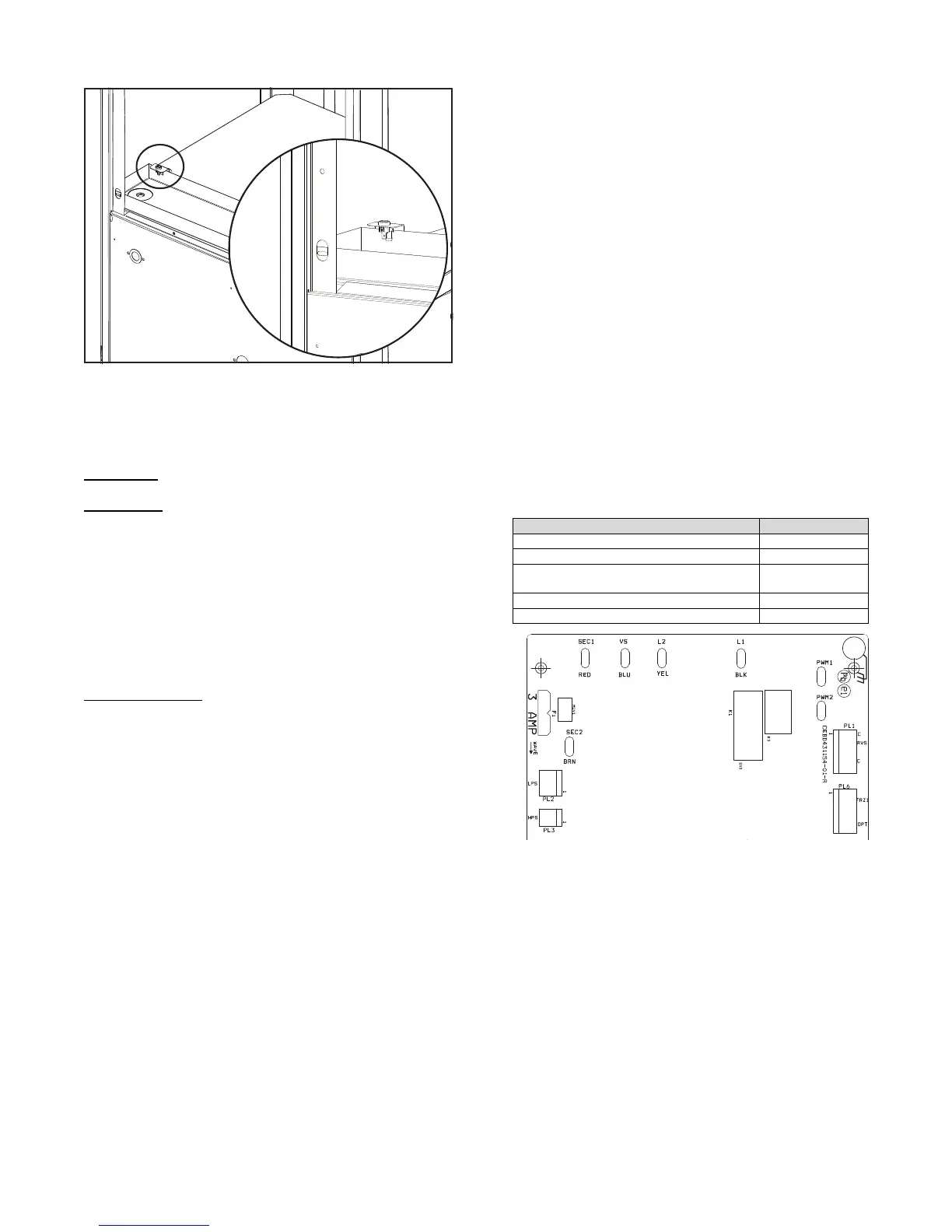

SCOMPRESSOR VOLTAGE SENSING: The control board input

termin als lab eled V S and L 2 (see F ig. 23) are u sed to detect

compressor voltage status and alert the user of potential problems.

The control continuously monitors the high voltage on the run

capacitor of the compressor motor. Voltage should be present any

time the compressor contactor is energized and voltage should not be

present when the contactor is de-- energized.

SCONTACTOR SHORTED DETECTION: If there is compressor

voltage sensed when there is no demand for compressor operation,

the contactor may be stuck closed or there may be a wiring error. The

control will flash the appropriate fault code.

If the control senses the compressor voltage after start--up and is then

absent for 10 consecutive seconds while cooling or heating demand

exists, the thermal protector is open.

The control de--energizes the compressor contactor for 15 minutes.

The control Status LED will flash the appropriate code shown in

Table 14. After 15 minutes, with a call for low or high stage cooling

or heating, the compressor contactor is energized. If the call for

coo ling o r h eating co ntin ues, th e co ntro l w ill energize the

compressor contactor every 15 minutes. If the thermal protector

closes, (at the next 15 minute interval check) the unit will resume

operation. If the thermal protector trips for three consecutive cycles,

then unit operation is locked out for 4 hours and the appropriate fault

code is displayed.

SNO 230V AT COMPRESSOR CONTACTOR: If the compressor

voltage is not sensed when the compressor should be starting, the

appropriate contactor may be stuck open or there is a wiring error.

The control will flash the appropriate fault code. Check the contactor

and control box wiring. Refer to Table 8 and Fig. 26.

Table 8 – UPM Voltage Detection

UPM Voltage Detection Fault Code

Brownout L1 and L2 46

Compressor voltage sensing VS and L1 74

230V line power disconnect detection on L1

and L2

47

Contactor shorted detection VS and L1 73

24V transformer Sec 1 an d Sec 2 No fa ults

Fig. 26 -- UPM Board

L1, L2, VS, SEC 1 and SEC 2 Locations

Loading...

Loading...